Single Stage Centrifugal Water Pump for Farm Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Stage Centrifugal Water Pump for Farm Irrigation

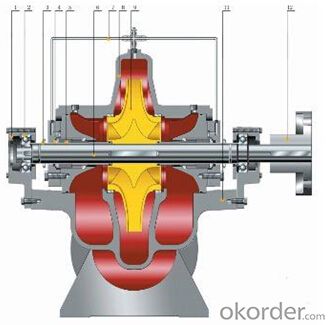

1.Single Stage Centrifugal Water Pump for Farm Irrigation Description

The Single Stage Double Suction Split Casing Centrifugal Pump is designed for Irrigation, The casting is axially split, which permits removal of the complete rotor whish moving either piping or motor. Pumps generating high heads have double volute to reduce radial forces. Replaceable wear ring protect the casting at the impeller running clearances. Flange drilled to ISO, DIN, BS or ANSI. The close double suction impeller gives practically zero axial forces. Each impeller is statically and dynamically balanced according to ISO 1940.The pumps have a reduced number of parts and extensive interchangeability, which leads to minimum levels of inventory for customers and faster parts delivery. Vertical installation is a standard option with the same upper and lower casing parts. It is mounted for a space-saving configuration or when apace is at a premium. Soft packing or mechanical seal, grease or oil lubricated bearing is optional. Oil lubrication is with constant level oiler.

2.Main Features of Single Stage Centrifugal Water Pump for Farm Irrigation

•Attractive design

•High efficiency, steady performance

•Big capacity, medium pressure

•High concentricity of components

3.Single Stage Centrifugal Water Pump for Farm IrrigationSpecification

Casing | Cast Iron, Ductile Cast Iron, Cast Steel, Stainless Steel or Duplex S.S |

Impeller | Cast Iron, Bronze, Duplex S.S, Stainless Steel |

Shaft | C-Steel, Cr-Steel, Stainless Steel |

Wearing Ring | Cast Iron, Brass, Stainless Steel |

Capacity/Q | Up to 25000m3/h, Up to 110000gpm |

Head/H | Up to 280m, Up to 800 feet |

Temperature/T | Up to 200degree |

Speed/n | 2900/1450/980/740/580 rpm 3500/1750/1180/890/710rpm |

4.Picture of Single Stage Centrifugal Water Pump for Farm Irrigation

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference.

- Q:I just had my water pump replaced and a coolant flush. 35 miles later, my MAL light came on and my mechanic said my thermostat needs replacement. Should this have been done with the water pump work, or could the work have caused the thermostat problem?

- Anytime I replace a water pump, intake gasket, or anything else where the coolant needs removal, I always suggest to my customers that we change the thermostat as well. Many times I just change it anyway. I tell the customers, but really don't offer an option! (of course if they say don't I will honor that, but no one has ever said that!) It is possible that during a flush some trash/scale got into the thermostat causing improper operation. With the thermostat removed, there is no restriction in the cooling system making flushing easier and more thorough. Now to answer your question, It is my opinion he SHOULD HAVE. That is not only an up-sell (even though I hate creating extra work) it is just an added value to the customer. He should also check belts and hoses, changing them (via customer approval) if needed. As a mechanic, the last thing I want is a comeback such as yours was because I at the very least didn't suggest a proper service!

- Q:Im looking at putting a cabin on my property. I have a 200 gallon underground fresh water tank and i'm needing a pump to get the water into the cabin. i want to run a toilet, sink and possibly a shower. does anyone know the style of pump i would need that would only operate when i need it to that way it does not burn up.

- I had a jet pump to run my whole house on my farm. It was placed in the basement, but it could be in a back room, too and they are pretty quiet these days. Does it freeze inside the cabin? I assume not. having it inside means if you have trouble even in freezing weather you can work on it in comfort. The end of the pie into your water tank will need a foot valve to keep the pipe filled so you don't have to prime the pump ( not a handy thing to have to do all the time). Other than that, the system is operated with electricity and a pressure switch which is settable. It will not run all the time this way. Not sure anymore but, for example the switch might be set to come on at 50PSI and shut off at 125PSI. You can tell by the switch or get a recommendation from the store where you buy it. (see pictures in link) Menard's sells these and department workers are trained to answer all your questions about installation, parts, and what you need,etc.

- Q:I have been quoted $600 to have a a water pump placed on my 2003 saturn vue. Also, another $300 if a thermostat is also needed. I cannot afford this at this time. Additionally, I have had problems with the car without reason all of a sudden not starting. Then, when I get the car to the mechanic it starts. It drives me nuts. Do I need to have the fuel pumps replaced? Do I need to replace both fuel pumps or just one, and which one?

- Depends on if it's the 4 or 6 cylinder model. The 4 cylinder is ran off the timing chain and will be very difficult requiring some special GM tools; the 6 cylinder engine would be much easier.

- Q:ok so i have a crack in my radiator a small crack but anyways yesterday it caused my car to over heat. i normally keep coolant in the car but it just got low and over heated pretty bad. so today the car is making a really loud annoying noise. coolant is also draining out of the bottom of the engine when the car is on. at a pretty good pace. it is coming out like right under the belt area so my friend said it is probably the water pump baring and he said it could have gotten damaged when it over heated. so i think these symptoms def point to the water pump. anyways i called a mechanic and he said that he had to change the belt to and he said he had to charge me $385. what you guys think. does he need to change the pump and the belt or just the pump? and is $385 a rip off or is that the going rate? thank you all for your knowledgeand information

- That water pump is driven by the timing belt. Usually when you do a timing belt or water pump it makes sense to change both now because they are both difficult to get to and you have to take off the same things for both. $385 is a bad price If you want to look smart about it, ask him to look at and check the seals, all he would be able to tell you is if they are leaking, if they are, ask him how much more. It's all worth it if the car is still good. We just did that on a friend's '91 and her's overheated a few times. She ha 235,000 miles.

- Q:it's not doing anything. about a month ago, i changed the pressure switch because it the water just suddenly stopped (like now), and after changing it, it worked again. I did noticed that after changing the pressure switch, it was tripping a lot (the pressure switch). when the water pump stopped again (this time), i went a bought another pressure switch thinking that it was the same problem, but this time it didn't solve the problem. Came to find out later, that the pressure switch that i had changed about a month ago, it was wired incorrectly - maybe that's why it was tripping a lot? so i did wired this one correctly, but still didn't work. Did i burned the pump? another note here is that it has been less than a year that i changed the water pump. My question is, what could the problem be this time? did i burned the pump because i wired the pressure switch incorrectly? any suggestion, please email me thanks!

- Easiest way to tell is to bypass the pressure switch and connect the pump motor wire directly to incoming power and manually run the pump until you reach shut off pressure... use your circuit breaker to do this.. My guess is that when you wired it the wrong the first time you forced the pump to shut off by way of an overload protector on the motor and either the protector is bad now or the motor is

- Q:can you give me some information?

- place a bucket outside when its raining

- Q:My father in law has a 95 jeep grand cherokee with the v~8 engine, the water pump started leaking so we went to autozone and bought a brand new duralast one with new gaskets, I'm gonna be putting it in when the weather lets me since i have to do it out on the street in front of the house, i was just wondering if anyone on here had any tips for me since i have never done one, I'm not a mechanic but i work on all my own vehicles since i am too poor to take them to a shop, i know a lot more about cars than he does so he asked me to help, it didn't look to hard but i'm not quite sure what im getting myself into, any advice or tips about this job is greatly appreciated. And please don't post telling me to take it to a mechanic as this is not a option for us, i will get it done i just thought somebody could help make it go a lil smoother with some pointers... Thanks

- make sure the when ya take the old one off that ya clean the surface real good where it bolts on. razor blade to take off any old gasket ect. some fine sandpaper to sand it down smooth for the new gasket helps to,just dont gouge it.use some of that red silicone in a tube,can get it at any auto parts, smear both sides of the gasket,the engine , and the water pump. let it cure out till its almost dry. bolt the new one on but when ya tightening it down do the bottom bolts first then the top bolts. add the antifreeze and check for leaks .good luck

- Q:Hello online mechanics! You guys have saved me a lot of money on my car, so now I have a new question! I have a 97 Ford Contour and lately since it's been cool in NJ, I've been hearing a tapping coming from the timing belt cover, but when the car warms up, there's no sound. I took the car to my mechanic and he says that I need to have the timing belt replaced, the pulleys adjusted, and the water pump changed. The price for doing the timing belt was $400 (including adjusting the pulleys) and $700 for the timing and the water pump. My question is ; do I need to do the water pump? He says that if you do the timing belt, that you should do the water pump too, but should I if there's nothing wrong with it ( as far as I know) and I'm not looking for the added expense? I thought if it ain't broke don't fix it still applies to things, or am I mistaken? Thanks guys gals! In these tough economic times, I'm not looking to spend any more than is necessary!

- ask some of your friends if they have a mechanic that they trust . Take the car to them and see if you get the same answer ?

- Q:the pump inlet how hard is this to replace i know the timing chain cover has to be removed and is this the propable place of the leak

- If okorder has printable online manuals for most repairs but if you aren't mechanically inclined and have little experience I would advise you to take it to a mechanic and have it fixed properly. Depending on the vehicle most water pump replacement cost between 2 and 3 hundred at a garage. The timing chain cover never needs to be removed to change a water pump.

- Q:i know a little bout cars always fixed my own since day one but this is the first car i have ever had/workd on with a internal water but thats driven off timeing chain my cars running hot and its holding prusser so i know its not radator or hoses but i need to know a way to check and make sure its the water pump befor i go tearing the engine apart

- When the car is running feel the hoses to see if the bottom hose is warm or not. If it is a lot cooler than the top one the water pump may not be working. Also turn on the heater to see if there is heat in the car. If there is heat inside the car the water pump is working. If the car is running hot while driving around town but runs cooler while driving on the highway the cooling fan may not be working properly. That car has a two stage cooling fan that is known for going bad. The low speed setting is the speed that is normally used and the high speed setting is used when the air conditioning is on. With that in mind you can try turning on the air conditioning to see if the motor cools down when it is hot. You will also want to see if the fan is coming on at all before you go too far and check the fuses and relays before you assume the fan motor is bad because they are around $100.00. Also I should note that I assumed that you have already checked the fluid level and thermostat. If not you need to check that first. Hope i have been helpful.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Single Stage Centrifugal Water Pump for Farm Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords