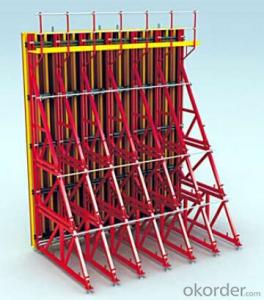

Single-side Bracket Steel formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

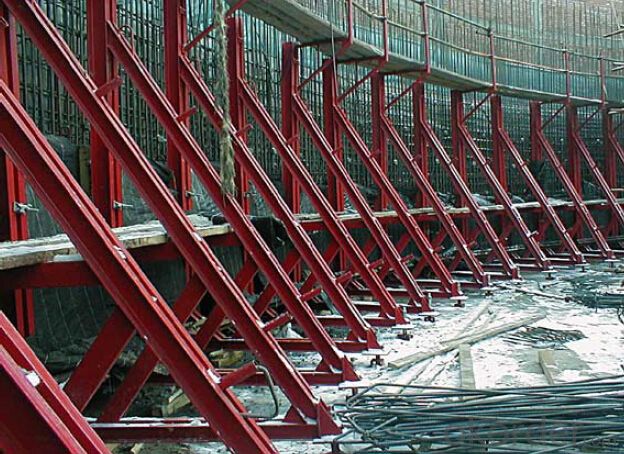

Single-side Bracket:

During single-sided concreting, the concrete pressure is transferred into the sub-structure by

means of the single-side bracket.

Characteristics:

◆ For concrete heights up to 8.0m and a fresh concrete pressure up to a maximum of 60KN/m2.

◆ Good standard performance and versatility.

◆ Fast element coupling, all units can be quickly connected.

◆ The finished wall is excellent and absolutely waterproof.

◆ Optimized sizes for transportation.

Design Principle:

There is no wall-through tie-rod in the single-side bracket system. The whole system is adjusted by

the anchor system and the regulator system.

The stress situation from the sketch above.F1 can resist the side pressure of the concrete and F2

can resist the rising force. R can not only bear the gravity force of the bracket, but also the side

pressure of the concrete. This stress system is simple, reasonable and also with convenience and

high safety.

- Q:What is the simple calculation method of the tunnel excavation unit price

- Parameter valuationThe valuation of parameter method is the method of calculating the multiplication coefficient according to a certain cardinal number or the custom formula. This method is simple and clear, but the biggest difficulty is the scientific formula, accuracy is difficult to grasp. This method is mainly applicable to the construction process must occur, but it is difficult to predict the specific items in the bidding, but can not separate the project content of the project measures. If the valuation night construction fees, two handling fee, rain during construction can be used in this method.

- Q:Who can give me detailed tunnel construction process

- Tunnel construction process, the first branch is a temporary payment, two lining is a permanent support.1, the hole before the edge, the construction of the slope (including drainage, electricity, etc.);2, the construction of large pipe shed3, measurement positioning line;4, drilling, blasting;5, slag, playing anchor, steel, injection (including the initial spray and spray)6, ahead of the anchor (after the pipe section)7, measuring the line;

- Q:What is the first project of tunnel constructionNow to do some of the tunnel program, you need to be the first to list out, a total of what? I know that the first branch, two lining, inverted arch, tunnel, pavement these

- YK24 + 300 ~ YK24 + + 288 as the first project of the tunnel engineering. There are many factors that affect the quality of the two lining construction, each link in the construction process must be strictly in accordance with the construction specifications

- Q:Two tunnel lining reinforced concrete template to price behavior can be contracted

- There is two times of lining concrete pouring, the normal price is within 100 yuan, this is the pure artificial price, does not contain steel trolley and various materials two tunnel lining.

- Q:When the tunnel fight, there is no provision to fight how many meters left, only by one of the construction

- Fixed strip: the use of additional reinforcement fixation; special fixture fixed; the wire and the fixed template (Figure 2).

- Q:The arch and the arch of the tunnel

- Tunnel arch wall refers to both sides of the tunnel wall and the top of the arch, the tunnel arch wall is generally the use of a template trolley.

- Q:I would like to ask the tunnel hydraulic trolley steel template design is the use of what software

- According to the design requirements, draw the spare parts drawings, and then workers in accordance with the production drawings!

- Q:I would like to ask the high-speed rail tunnel invert small side wall and arch with the small side of the wall of the hanging formwork of what a good method?

- Die casting. Install the inverted L hanger on the side wall.

- Q:What is the concrete construction of the tunnel invert

- The construction of concrete is related to the non - construction concrete

- Q:How to design the general layout of the tunnel construction organization design

- A very simple plane diagram, indicating the location of the tunnel, into the construction of the sidewalk and the construction of sidewalks, mixing stations and storage yard, air compressor unit location

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Single-side Bracket Steel formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords