Single-Side Bracket For Engineering

- Loading Port:

- XINGANG

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set/Sets set

- Supply Capability:

- 10000 Set/Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.INTRODUCTION OF Single-Side Bracket for Engineering

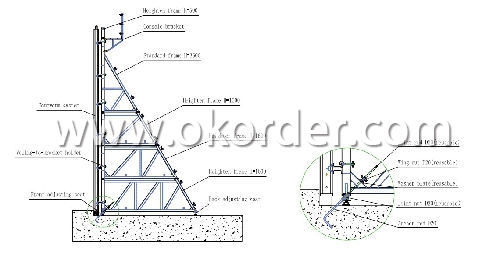

During single-sided concreting,the concrete pressure is transferred into the sub-structure by means of the single-side bracket.

2.CHARACTERISTICS OF Single-Side Bracket for Engineering

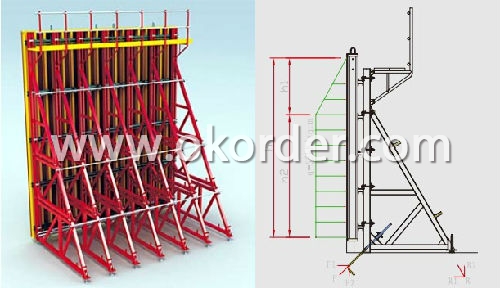

1.For concrete heights up to 8.0M and fresh concrete pressure up to a maximum of 60KN/M2

2.Good standard performance and versatility

3.Fast element coupling,all units can be quickly connected.

4.The finished wall is excellent and absolutely waterproof

5.There is no wall-through tie-rod in the single-side bracket system.The whole system is adjusted by the anchor system and the regulator system.

6.The stress situation from the sketch above.F1 can resist the side pressure of the concrete and F2 can resist the rising force.R can not only bear the gravity force of the brackt,but also the side pressure of the concrete.

7.This stress system is simple,reaonable and also with convenience and high safey.

3.ADVANTAGES OF Single-Side Bracket for Engineering

1.Easy Application: Design and form planning ensuring easy application.

2.Flexibility: Easy adaptation to different projects and sizes thanks to its size variety. The single-side braket can be used with other form systems.

3.Light Weight: It is lighter than all form systems in class. Thanks to this, it allows working with low crane capacities.

4.Easy Assembly: It provides easy on-site assembly thanks to connection details.

5.Economy: It is an economic system with its easy assembly, light structure and flexible and fast application.

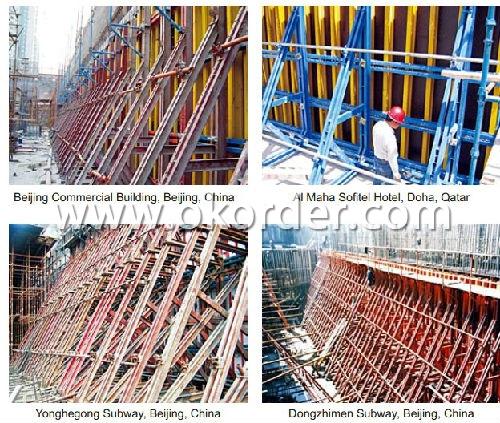

4.PROJECT APPLICATION OF Single-Side Bracket for Engineering

- Q:The whole concrete wall climbing frame or good use of steel scaffolding

- Floor scaffold:Advantage:1) large bearing capacity. When the scaffolding geometry and structure comply with the relevant requirements, under normal circumstances, the bearing capacity of 15kN ~ 35kN of the single column scaffold (1.5tf ~ 3.5tf, design value).Clamp and Tube Scaffold2) easy to install and disassemble, set up flexible. Because the length of the steel tube is easy to adjust and the fastener is convenient to connect, the utility model can be used for various buildings and structures with various planes and elevations.3, compared with the economy, the processing is simple, and the investment cost is low; if the geometric dimensions of the scaffold are carefully designed, and the utilization rate of the steel tube is improved, the material consumption can also obtain better economic effect. Fastener steel pipe frame equivalent to 15 square meters per square meter of construction steel.

- Q:What is an integrated climbing frame? What are the works? What are the advantages

- The climbing frame, which is also called the lifting frame, can be divided into several types, such as hydraulic, electric, manual and so on. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction.

- Q:Advantages and disadvantages of climbing frame and floor type scaffold

- 2) easy to install and disassemble, set up flexible. Because the length of the steel tube is easy to adjust and the fastener is convenient to connect, the utility model can be used for various buildings and structures with various planes and elevations.

- Q:What are the maintenance and maintenance of hydraulic climbing formwork

- Regular inspection of the climbing device should check the connections. In particular, the following parts of the site to focus on inspection and reinforcement: according to the design requirements of the bolt with spring washers

- Q:Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Climbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction. It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material. And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings.

- Q:The difference between the scaffold and the scaffold

- Climbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction. It can climb up or down the building. This system makes the change: one is the scaffold without turning over shelf, two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material. And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings.

1. Manufacturer Overview |

|

|---|---|

| Location | Shanghai,China |

| Year Established | 1949 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia Domestic Market |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | SHANGHAI |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 200 |

| Language Spoken: | English,Chinese |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Single-Side Bracket For Engineering

- Loading Port:

- XINGANG

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set/Sets set

- Supply Capability:

- 10000 Set/Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords