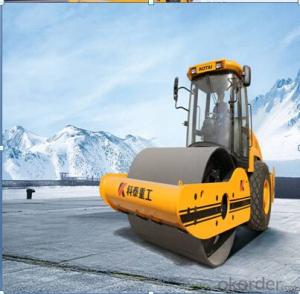

Single Drum Vibratory Rollers LSS2301 for sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 35 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Heavy duty vibratory rollers are suitable for compaction of non-cohesive materials such as gravel, crushed stone, sand-macadam mixture, sandy soil and rock filling etc. on base course sub-base and embankment fill construction etc., which are ideal equipment for high-class highway, railway, airport, harbors, dams and large-scale industrial ground etc.

High powerful D6114 Water cooled turbocharged diesel engine; Engine cooling air-path structure and large capacity of fuel tank.

Heavy-duty gearbox; Driving axle with greater braking torque .

Dual amplitude setting of vibration; New types of vibration device and drum travel bearing structure.

Modernized style overall appearance; Driver's cabin with T type angular glasses.

Joint-moving mechanism of the clutch pedal with engine throttle; Adjustable instrument desk with liquid crystal instrument panel.

Welcome you to visit our factory in China. Anything we can do, please feel free to let us know. We are sure your inquiries will get our prompt attention.

- Q:How much is the front toughened 20t vibratory roller in the old section?

- Glass cheap, depends on what you are glass front or side of the professional roller

- Q:Roller brake lock why

- 3, wear plate return tension spring failure;4, the brake master cylinder push rod to adjust properly, there is no freedom of travel (four wheel lock);

- Q:The vibratory roller is rolled back and forth several times at a time

- From the left to the right, or from the right to the left, roll the construction area once, as far as the lap of the previous work area is concernedGenerally, when the actual construction is not calculated, the number of rolling, as long as the road roller can not stop

- Q:XCMG vibratory roller XP and XS? What do you mean?

- As the global economy is still in a slow recovery period, coupled with China's Roller Road enterprises export major market recovery is weak, in 2013, the road roller exports situation has improved, but the growth rate is weak. In 2013, the roller main production enterprises exported 3395 rollers, an increase of 1.8%. More than 200 enterprises export roller this year, Xugong, Xiagong, Liugong, Luoyang Road, Liuzhou, mountain and other 6 enterprises. This one, because of the influence of brand and overseas channels, up to 752 units of export Xugong roller, total sales of 18.5%; export 693 units Xiagong roller, has accounted for 42.6% of total sales; Liugong exports 556 units accounted for 39.85%.Beg for adoption

- Q:Roller models

- The national standard is YZ, which belongs to vibratory roller, Y is static roller, S stands for hand, and D stands for oscillation. The figures behind are generally quality of work.

- Q:The dangers of young people turning on rollers

- Negatively speaking, lack of social experience is actually eat less, so you eat more slowly understand why the boss says that they make pressure on how how pressure, not with his nonsense, you say to him, he more angry, more than 10 hours a day and the boss asked people, a person carry not to live! I also drive the road ~ in the construction site must listen to.

- Q:Will the Apocalypse Tank be pressurized back?

- but also not explosion damage, the armor is even more powerful, not simply rely on the weight can be crushed,

- Q:XCMG vibration roller 14J and 14JC what is the difference?

- To say something bad is actually something that was flawed or promoted before, but it didn't work out at that time.Or it will be better after practice to find improvements in some places, so there is a slight difference.

- Q:How many meters does this roller advance per minute? What is the area of the road that has been pressed per minute?

- 12 meters per minute, the road area under pressure is 19.2 square meters.

- Q:What's the difference between a three wheel roller and a two wheel roller?

- Three roller is the static compaction, without vibration function, used for compaction of embankment or base, two roller generally called double drum vibratory roller, roller tonnage than three small tonnage, mainly used for oil pressure, the asphalt concrete, with vibration function, the upper two wheels a water tank, can go on wheels to prevent water roller compacted asphalt concrete glued to the wheels.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Single Drum Vibratory Rollers LSS2301 for sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 35 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords