Single Component Polyurethane Coating All Colors

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Component Polyurethane Waterproof Coating Introduction

Single-component moisture-curing pure polyurethane waterproof coating is a kind of liquid polymer waterproof material,

suitable for dry and wet base surface construction, solidified into tough and elastic, non-toxic and tasteless waterproof

film after coating. It is a new type of environmental friendly waterproof material without solvent.

Single Component Polyurethane Waterproof Coating Application

•Building roof

•Concrete

•Wall

•Water Tank Structure

•Floor(kitchen floor, bathroom floor ect)

•Underground Tunnel

•Sewerage Structure

•Movement Joint

•Wet Area, Pipes, Sewer & etc.

Single Component Polyurethane Waterproof Coating Advantage

1.water based and solvent based

2.Solid content above 80%

3.Durable performance, UV resistant, ageing-resistant,resistant high and low temperature,antifatigue, withstand constant immersion in water

4.Good splicing performance

5.Operate conveniently, low viscosity

6.Can splicing with concrete and many kinds board stuff

7.Will not change color after used

8.Apply for Roof,Swimming Pool,Tank and more

Single Component Polyurethane Waterproof Coating Specifications

NO. | Items | Ⅰ | Ⅱ |

1 | Tensile Strength MPa≥ | 1.9 | 2.45 |

2 | Elongation at Break %≥ | 550 | 450 |

3 | Tearing Strength N/mm≥ | 12 | 14 |

4 | Bend at Low Temperature°C≤ | -40 | |

5 | Unpermeability0.3MPa 30min | Impermeable | |

6 | Solids Content%≥ | 80 | |

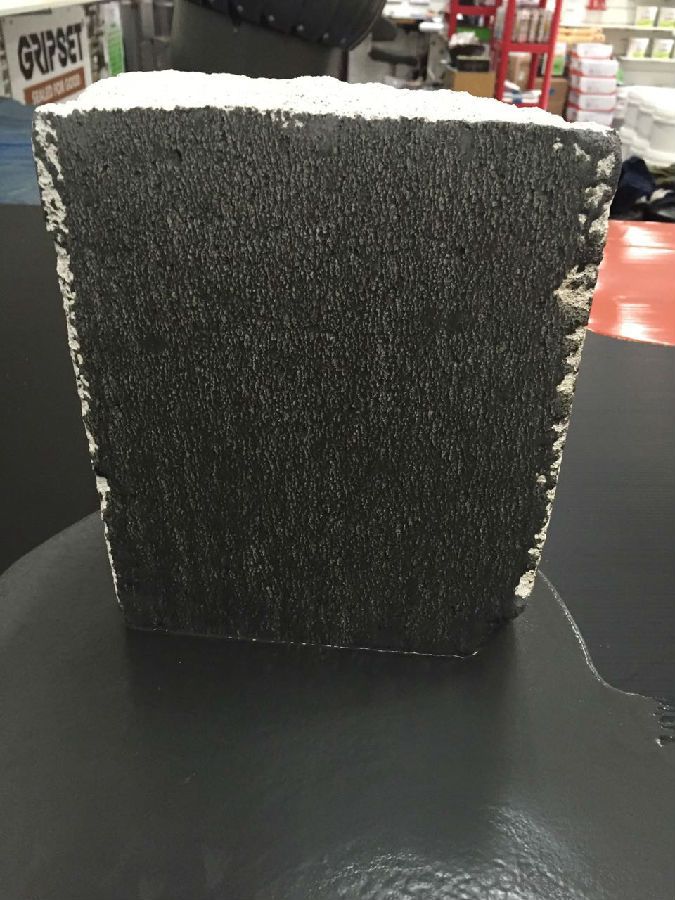

Single Component Polyurethane Waterproof Coating photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q:Villa roof leakage what general reasons, what materials to remedy

- First, the roof leak to find the first leak, looking for the main leak from the roof to the lower to find leakage. First look at the roof there is no crack, the original waterproof layer is not aging, the roof of the original waterproof membrane has no bubbles, there are bubbles to prove that the water has entered the bottom of the waterproof layer, and thus leaking, and roof On the gutter there is no clogging.

- Q:Roof leakage, what materials do the best waterproof

- First, the roof leak to find the first leak, looking for the main leak from the roof to the lower to find leakage. The first is to see if there is no cracks in the roof, the original waterproof layer is not aging, the roof of the original SBS waterproofing membrane has no bubbles, there are bubbles to prove that the water has entered the bottom of the waterproof layer, and thus leaking. There is a block on the roof of the gutter is not blocked in the countryside, there are still a large number of tile-roofed house, when the tiles due to damage caused by the roof leakage, as long as the replacement of tiles can be, this step is also known as "

- Q:How can the toilet waterproof works fail?

- Use 755 new waterproof material can be painted three times. There is also a new type of waterproof material is water-like brush is also three times, you can go to the building materials market to see, you know.

- Q:Cabinet is to buy finished products, or directly to the decoration company to do?

- Do the cabinet can be in accordance with your size, finished cabinet moldy, which is not necessarily. You have to buy some of the Well

- Q:What are the materials used in the ceiling?

- Kitchen bathroom ceiling material 4: sauna board ????This is a dedicated wood panel for the sauna, but it can also be used in the kitchen and bathroom, generally degreased, with high temperature, not easy to deformation, health and environmental protection and other characteristics, even if there is a long time in the water Will not rot, usually painted in a layer of paint decoration, can make the overall ceiling more beautiful.

- Q:Oriental rain rain waterproof how to

- Oriental rain rain waterproof paint is not good to say it, but real to do it, rely on the quality of their own business for the relentless pursuit and practice. Oriental rain rain waterproof coating from the selection to the production to the final product testing are as much as possible meticulous.

- Q:I would like to ask how to do in the warm water above,

- Do not know why you are in the floor to do the top of the waterproof? The We are here in the northeast of the winter is very cold, are warm, no one to warm the ground to do the above water, I think you over and over again, ah, no need, every family is warm, you have to do waterproof in the above is afraid of soaking your floor or tiles Bubble? The If the pipe really leaked, did not use the waterproof, the first warm tube must be selected, followed by your shop is good or bad, workers, water, are very important, you focus on this line on the line

- Q:What is the price of a waterproof window cover?

- 3, decorative panels Decorative panels are divided into paint-free panels and paint panels. Currently on the market, there are many window-free products, paint-free board is 5 mm density, the board pressure a layer of thin layer of color paper, due to the type of color paper, so there can be a lot of paint-free Color. Paint decorative panel is the surface of a layer of veneer plywood, there are many types, different wood has different colors. The benefits of window sets

- Q:Waterproof mortar expensive or dry mortar expensive

- Dry mortar is usually called hydraulic cement mixed mortar, refers to the dry sieve treatment of aggregate (such as quartz sand), inorganic cementing materials (such as cement) and additives (such as polymers) and so on a certain proportion of physical mixing Into a granular or powdered, in the form of bags or bulk transported to the site, add water, mix directly after the use of materials.

- Q:How to do waterproof bathroom, construction process is what

- 4, closed water test. Closed water test, the highest point of the ground water can not be less than 2 cm, save at least 24 hours, observe the phenomenon of no leakage after the operator. If there is leakage, need to redo, and can not neglect.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Single Component Polyurethane Coating All Colors

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords