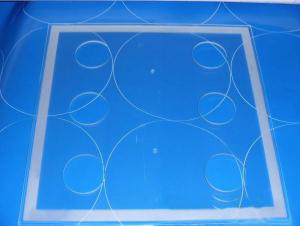

Silkscreen Printing Glass-4

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Silkscreen Printing Glass is a kind of glass on which inorganic enamel is printed by silkscreen printing machines. After being printed on, it will be dried and heated under high temperature to make the enamel adhere to the glass lastingly.

- Q:What kind of raw materials should be used in making FRP?

- Synthetic resin is a kind of synthetic molecules by a large amount of polymer, usually called polymer, also known as synthetic resin in polymer. The performance after heating is different, can be divided into thermosetting resin and thermoplastic resin two categories.Thermosetting resin refers to the heat or curing agent (including initiator) under the action of crosslinks and become insoluble and infusible solid state of a kind of resin, such as epoxy resin, phenolic resin, unsaturated polyester resin, furan resin. This resin can not soften cured after heating. High temperature decomposition and destruction.

- Q:What is the difference between FRP and carbon fiber?

- Glass fiber (formerly known as English: glass fiber or fiberglass) is a kind of excellent inorganic non-metallic materials, variety, has the advantages of good insulation, strong heat resistance, good corrosion resistance, high mechanical strength, but the disadvantage is brittle, poor wear resistance. It is a glass ball or waste glass as raw materials by high temperature melting, wire drawing, winding and weaving process for production, the filament diameter of several microns to twenty micron, the equivalent of a hair 1/20-1/5, each bundle of fibers by hundreds or even thousands of root root filaments. Glass fiber is usually used as reinforcing material in composite materials, electrical insulation materials and insulation materials, circuit boards and other fields of national economy.

- Q:Chemical materials and additives needed for the production of glass

- The production process of float glass is introduced by taking ordinary production line of daily melting capacity of 600 tons in China as an example.Float glass is made in tin bath. The length of the whole production line is about 500 meters. It can produce 550 to 600 tons of glass every day. It is equivalent to 3 meters wide, 3 millimeters thick, and the glass belt is about 25 kilometers in length. Once started, 24 hours a day is uninterrupted until the furnace is stopped for about 8-10 years. Float production is the main mode of production of flat glass

- Q:What kind of mineral is glass made of?

- Protective glass (in the ordinary glass manufacturing process to add appropriate auxiliary material, so that it has to prevent light, heat or radiation through the protection of personal safety function. Such as grey - dichromate, iron absorption in the ultraviolet and visible light; blue - Green nickel oxide, FeO absorb infrared and visible light; lead glass - lead absorption of X rays and R rays; dark blue - dichromate, ferrous oxide, iron oxide, UV absorption infrared and most visible light; adding cadmium oxide and boron oxide absorption neutron flux.

- Q:Polypropylene short fiber and glass fiber if different

- Polypropylene fiber is resistant to acid and alkali, and glass fiber has poor alkali resistance.

- Q:Not man-made destruction, why toughened glass suddenly broken?

- This is because of containing nickel sulfide crystal glass raw material, manufacturing technology in the world is any existing can not be completely avoided, only reduce the exploding probability through control of the purity of raw materials and processing technology to a.It blew the concept of rate, the national standard of our country only glass project on the wall, I do not know whether the other foreign industry to use the toughened glass also has detailed provisions.

- Q:List and characteristics of chimney glass flake cement

- Coatings containing glass flakes are much harder than epoxy or polyester resin without glass flakes, and therefore have higher surface abrasion resistance.

- Q:What are these things that belong to the reactor's raw materials?

- The raw material of the reactor is very simple. Dry reactor, if it is hollow, only aluminum (copper) line plus aluminum (copper) card, and then poured into resin, winding may also be used glass fiber belt

- Q:What is the glass DV board made of?.

- The chemical composition of ordinary glass is Na2O, CaO, 6SiO2, the main component is silica, is a kind of amorphous structure with irregular structure. Widely used in buildings for wind and light transmission; of mixtures. There is also colored glass mixed with certain metal oxides or salts, and toughened glass made by special methods. Sometimes some transparent plastic (such as polymethyl methacrylate) is also called organic glass.

- Q:What is acrylic material?

- Acrylic properties;1. excellent transparencyColorless transparent plexiglass plate, light transmittance of more than 92%2. excellent weather resistanceAdaptability to the natural environment is very strong, even for a long time in sunlight, wind and rain will not change its performance, anti-aging properties, and can also feel comfortable in the outdoor use.3. good processabilityThe utility model is suitable for mechanical processing and easy thermal forming, and the acrylic plate can be dyed, and the surface can be painted, silk screen or vacuum coating.4. excellent comprehensive performanceAcrylic plate has many varieties, rich colors and excellent comprehensive properties. It provides diversified choices for the designers. The acrylic board can be dyed, and the surface can be painted, silk screen or vacuum coating.

Our main product is glass, such as tempered glass, furniture glass, building glass, silkscreen printed glass, painted glass, sandblasted or acid etched glass, and more. Our products are widely used for architecture, electronics, and furniture, such as table tops, coffee tables, LCD TV bases, refrigeratory or air-condition front panels, exchange rate indicators, horologe panels, induction cooker panels, cabinets, shower glass doors, and other furniture.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China |

| Year Established | 1989 |

| Annual Output Value | US$ 1.0-1.5 Billion |

| Main Markets | Mid East; Eastern Europe; Southeast Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shenzhen, China |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 100,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Silkscreen Printing Glass-4

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords