Silimanite Brick SAS60B

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t

- Supply Capability:

- 500 Tons Per Month m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silimanite Brick---SAS60B

General Information of Silimanite Brick SAS60B

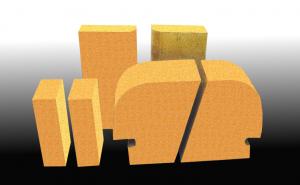

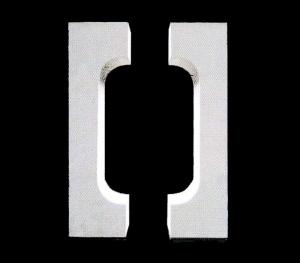

Silimanite bricks are made from silimanite raw materials. The SAS60B silimanite bricks have 60% alumina content with low iron content. It offer better CO-resistant properties. The SAS60A silimanite bricks are produced by sintering under high temperature. And a wide range of shapes are available.

Characteristics of Silimanite Brick SAS60B

Compared with the high alumina bricks, silimanite bricks have better properties with the following features:

High tensile strength

Thermal shock resistant

Strong resistance to crossion

Typical Application of Silimanite Brick SAS60B

The silimanite bricks could be applicated in the steel and non-ferrous metals industry, which are in direct contact with liquid metal are possible. The SAS60B sillimanite bricks are good for refractory solutions in the glass industry, cement industry and incineration, for industrial processes with rapid thermal shocks, in furnaces for firing biomass and in production kilns of the ceramic and refractory industry.

Technical Data of Silimanite Brick SAS60B:

|

Sintered Silimanite Brick---SAS60B | ||

|

Physical Properties: |

|

|

|

Refractoriness |

℃ |

1790 |

|

Apparent Porosity |

% |

18 |

|

Bulk Density |

Kg/m3 |

250 |

|

Cold Crushing Strength |

Mpa |

70 |

|

Refractories Under Load(0.2Mpa) |

℃ |

1600 |

|

Reheating Linear Change (1500 ℃x2h) |

% |

+0.1~-0.2 |

|

Chemical Analysis: |

|

|

|

Al2O3 |

% |

60.0 |

|

SiO2 |

% |

37.0 |

|

Fe2O3 |

% |

1.2 |

|

Note: Technical Data are typical average results from test pieces.The technical data is offered solely for your consideration.And CNBM reserve the right to modify the technical data without any prior notice.Users of CNBM products should make their own tests to determine the suitability of each products for their particular purposes. | ||

We has success in silimanite bricks due to their cost-effectiveness, excellent thermal shock resistant and resistant properties. CNBM also has experience in silimanite application and would like to assist you in product selection, system design, and installation techniques.

- Q:What kind of refractory material will be used in the glass kiln?

- 5. fused zirconia corundum brick (AZS brick)The chemical composition of the brick is ZrO234%, Al2O349.2%, SiO215.9%. The bulk density is 3.85g/cm3, and the main uses are the melting part, the burner brick and the feeding port brick.6. fused chromium corundum brickThe chemical composition of the brick is Cr2O328.3%, Al2O358.3%, MgO, Fe2O35.2%. The bulk density is about 3.4g/cm3. A flue interface brick that is mainly used at the entrance of the heat exchanger.

- Q:What refractory materials are adopted in each part of the blast furnace?

- The furnace throat is a part of the direct impact and friction when the burden drops, and the high density and high alumina brick is usually adopted. The upper and middle shaft temperature is only 400~800 degrees, the parts with high alumina brick and sillimanite brick. The lower part of the shaft due to high temperature and dust by scouring and alkali metal vapor erosion, so the requirements for the slag resistance, alkali resistance and high temperature resistance, wear resistance of high quality clay brick, high alumina brick, carborundum brick or corundum brick. Belly temperature reaches 1400~1600, and slag, steam erosion, erosion and corrosion is strong, therefore, the silicon carbide reaction bonded silicon carbide brick.

- Q:Is it good for your cupola to use that kind of refractory, high aluminum brick, clay brick or red silica?

- The high aluminum clay brick is slightly more stable and can be used!

- Q:I am a student of refractory materials. I would like to know the general rank of national refractory materials company

- Zhejiang Sunon Refractories Co., Ltd. is a group member of the factory of industrial economy research China (country), building materials building materials industry center Changxin Branch Center of refractories. The main products are: wear-resistant refractory brick, aluminum silicate fiber board, ordinary magnesia, heavy casting materials, spalling brick kilns, special casting materials, high strength and abrasion resistant castable refractory castable, special pulverized coal burner, MF-170 coating (with fabric), clay brick, corundum wear-resistant plastic, calcium silicate board, lightweight castable and the direct combination of magnesia chrome brick, unburned magnesia chrome brick, anti flaking high alumina brick, mullite brick, antiskinning castable,

- Q:Sillimanite brick

- After calcination at high temperature, sillimanite transforms to mullite and free silica. Generally use the firing process and production of high temperature mud casting method. Its physical and chemical properties are better than those of aluminum bricks, the refractoriness is 1770~1830 degrees, and the load softening point is 1500~1650 degrees centigrade. The utility model is mainly used for the forming of a liquid hole in a glass furnace, a lining of a blast furnace, a furnace throat and a ceramic industrial kiln tool.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 83 Million |

| Main Markets | North America;Eastern Asia;Southeast Asia;Western Europe;Middle East;Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 60% - 70% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 20,000 square meters |

| No. of Production Lines | Above 14 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Silimanite Brick SAS60B

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t

- Supply Capability:

- 500 Tons Per Month m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords