Silicon Polycrystalline Solar Panel 310W

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200000 watt

- Supply Capability:

- 20000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ABOUT US

We are a high-tech group wich specializes in solar products design,research, manufacture, sales,solar projects design and installation.

Our national sales service covers seven parts, including northeast, north, east, middle, south, northwest and southwest, international sales covers five continents and over forty countries, including Germany, Italy, Spain, France, America and Brazil etc.

INTRODUCTION

This installation Manual contains essential information for the electrical and mechanical installation that your must know before installing CUSTOMER PV modules. This also contains safety information you need to be familiar with .All the information described in this manual are the intellectual property of CNBM and based on the technologies and experiences that have been acquired and accumulated in the long history of CUSTOMER. This document does not constitute a warranty, expressed or implied.

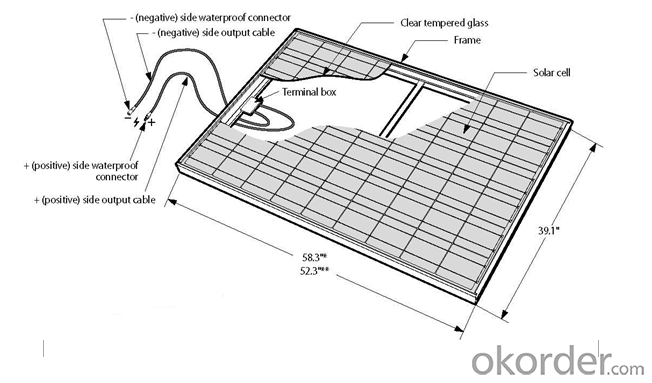

COMPONENTS

DATA SHEET

Maximum power | 310W |

Cell type(mm) | Polycrystalline solar cell 156*156 |

Number of cell(pcs) | 72(6*12) |

Manufacture site | China |

Open-circuit voltage(voc) | 45V |

Maximum power voltage(vmp) | 37V |

Short-circuit current(isc) | 8.8A |

Optimum operating current(imp) | 8.38A |

Power tolerance | 0~+5W |

Module efficiency | 16% |

Dimensions(mm) | 1956*992*40 |

Weight | 27 kg |

Backsheet | Silver |

Frame Colar | White |

Frame | Anodized Aluminum Alloy |

Process is as follows:

1, the battery test

2, positive Welding - Inspection –

3, on the back of cascading - Inspection –

4, laying (glass cleaning, material cutting, glass pre-processing, laying) –

5, laminating –

6, to flash ( to the side, cleaning) –

7, fitted border (glue, loading angle keys, punching, install box, scrub I glue) –

8, the welding junction box –

9, high-pressure test –

10, component testing -- -

11 appearance inspection, packaging and storage;

- Q:How do solar panels affect the aesthetics of a building?

- Solar panels can have both positive and negative effects on the aesthetics of a building. On one hand, solar panels can enhance the visual appeal of a structure, adding a modern and sustainable element to its design. They can be integrated seamlessly into the architecture, creating a sleek and futuristic look. On the other hand, some people may find solar panels visually unappealing, especially if they are not well-integrated or if they cover a significant portion of the building's surface. Ultimately, the overall impact on aesthetics depends on the design, placement, and integration of the solar panels.

- Q:Can solar panels be used in conjunction with energy-efficient appliances?

- Yes, solar panels can definitely be used in conjunction with energy-efficient appliances. In fact, pairing solar panels with energy-efficient appliances is a great way to maximize the benefits of renewable energy and reduce overall electricity consumption. By generating clean electricity from the sun, solar panels can power energy-efficient appliances, resulting in significant energy savings and a more sustainable lifestyle.

- Q:i want to join multiple solar panels into a bank so i only need one length of wire, i am going to use diodes to stop them sending power back into the one before it. is this ok or do i need something else?

- It sounds like you intend to put them all in parallel, since you mention blocking diodes. If the panels are all roughly the same voltage, that should work. Mismatched panels will also work, but there may be little to no contribution from the lowest voltage ones if they are severely mismatched.

- Q:Can solar panels be used to power a concert venue?

- Yes, solar panels can be used to power a concert venue. By installing a sufficient number of solar panels, a concert venue can generate enough electricity to meet its power requirements, including stage lighting, sound systems, and other electrical equipment needed for the event. Additionally, solar panels can help reduce the venue's carbon footprint and dependence on traditional energy sources, making it a more sustainable and environmentally friendly choice.

- Q:Why does the new 200 Toyota Prius have solar panels at the top of the vehicle?

- The solar panel powers the fan in the solar-powered ventilation system. The ventilation system helps to keep your car cool while parked out in the sun. If your car is cooler, then when you get into it after parking somewhere the AC won't have to work quite so hard to get you comfy when you start your car. Less AC use means less hybrid battery use (since the hybrid battery powers the AC), which means that your gasoline engine will run less (to recharge the hybrid battery), meaning better fuel economy for you.

- Q:How do solar panels affect the roof's structural integrity?

- Solar panels do not significantly affect the roof's structural integrity. They are typically lightweight, and their installation involves mounting them securely onto the roof without causing any damage or weakening.

- Q:if so, would it be possible to make (or remake) an organism that could subsist off of sunlight and external heat like plants?

- There are, in fact, protozoa that use chlorophyll to harvest sunlight, but the thing is, they also MOVE. So it's not entirely unreasonable that an animal cell could do the same.

- Q:Can solar panels be installed on a multi-story building?

- Yes, solar panels can be installed on a multi-story building.

- Q:Can solar panels be used to power a data center?

- Yes, solar panels can be used to power a data center. Solar energy can be harnessed through photovoltaic panels and converted into electricity to power a data center's operations. This approach helps reduce reliance on traditional energy sources and promotes sustainability. However, the feasibility and effectiveness of using solar panels will depend on factors like the size of the data center, available sunlight, and energy requirements.

- Q:How does Solar Panel make Electricity ?

- photons excite electrons in the silicon to a higher energy level

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Silicon Polycrystalline Solar Panel 310W

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200000 watt

- Supply Capability:

- 20000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products