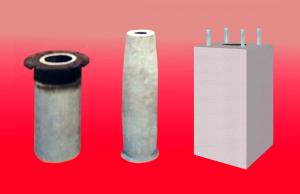

Silicon Nitride-Carborundum Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

This kind of brick is used for Precalciner and the tertiary air duct of cement kiln,

And have a high resistance to spalling

Brand Index | S70 |

MgO |

|

Al2O3 | ≥ 70 |

Cold Crushing strength Mpa≥ | 50 |

Apparent Porosity %≤ | 23 |

Bulk Density g/cm3≥ | 2.5-2.6 |

Refractoriness Under Load(°c ) | 1470 |

Silicon refractory brick is one type of the refractory prodution, consisted of tridymite/cristobalite and little amount of quarts and glass phase.It is manufactured with the material of nature silicon rock.Its SiO2 content is above 94%. And meanwhile it has high bulk density,high refractoriness tempreture,good corrossion resistant property,good slag resistant property,high refractoriness underload and good stability in the super high tempreture.

Our silicon refractory brick has been used in many blast furnance air heater, in many famous steel mill factories and many other steel factories .The silicon brick is always used to bulid the walls around the air heater above the regenerative chamber and the top hat of the air heater sotven.Cause this part of air heater bears highest tempreture of the hot wind.So this part of the air heater requires the best refractoriness and stability for the structure.

- Q:Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- It is in the production process, zirconium corundum bricks are likely to cause pollution.Fused zirconia corundum brick is also called AZS AZS English is abbreviated to AZS, is based on three chemical composition of Al2O3 - Zr02 - Sio2 phase diagram of three component system, according to the content of the order, Al2O3 A, Zr02 Z, Sio2 S, national standards for the use of this abbreviation, such as No. 33 cast brick, abbreviated as AZS, 33#, No. 36 fused zirconium corundum brick, abbreviated as AZS, 36#, No. 41 fused zirconium corundum brick, abbreviated as AZS - 41#.

- Q:What's the size of the fused zirconia corundum refractories for glass furnace? What are the main kilns? How much is the dosage?

- Fused zirconia corundum refractory material of glass fiber kiln quantity is little, generally used in the kiln feed arch furnace flue, where large amount of places are currently using dense zirconium Zr, dense chromium

- Q:How to improve the induction furnace campaign, from the promotion of refractory life start

- According to the use of atmosphere, choose the appropriate spraying materials, such as infrared radiation paint

- Q:What kind of refractory material will be used in the glass kiln?

- The content of ZrO2 in the brick is about 66%, and the bulk density is 3.7g/cm3, which has better thermal stability and anti stripping property. The use of erosion serious investment outlet area and after the parapet wall in the powder melting furnace, observation hole brick and pathway of flame space and roof parapet wall brick, brick burner. But there are also AZS burner brick with mullite brick for brick kiln and transition two side clearance brick etc..

- Q:What is the price of concrete self insulation bricks?

- Insulation brick prices also have a great relationship with the material and workmanship, such as clay brick price is much lower than high alumina brick, mullite and corundum brick prices will be higher.

- Q:How do corundum bricks bind?

- High temperature bonding clay can be used for bonding masonry

- Q:Wave tile and throwing glaze, tile which good?

- These two tiles have their respective advantages and disadvantages, in fact, to say which kind of good, mainly depends on the decoration of personal preferences and the location of the shop. If it is only the shop wall, then design and pattern rich whole glazed tile is good, it can make the room impressive, improve decorative effect, make the decoration style to fit the characteristics of his personality. In addition, clean up is relatively easy, not easy to contaminated with oil stains and other pollutants. If it is laying floor tiles, tile Douglas suggested the use of tiles, tiles of good antiskid effect, water absorption rate is relatively low, so the kitchen toilet bathroom and other wet places is not easy to water seepage, improve the convenience of life.

- Q:What problems should we pay attention to in the use of fused zirconia corundum brick (fused zirconia corundum brick) in glass furnace?

- Cast brick and clay brick masonry contact, eutectic phenomenon will occur at 1300 degrees Celsius, the selection of refractory materials, should avoid eutectic phenomenon serious two kinds of refractory materials such as brick masonry contact, in the following cast brick, the most vulnerable to erosion fused zirconium corundum brick.

- Q:What's the jade stove for?

- Corundum furnace for corundum smelting furnace, usually electric arc furnace for smelting dense corundum, corundum, white corundum, zirconia corundum, magnesia, magnesium aluminum spinel and fused refractory materials, professional design, Xi'an Xinda furnace engineering limited liability company manufacturing corundum furnace.

- Q:What refractory materials are used in industrial furnaces?

- Refractory materials use high temperature function to master all kinds of refractory material function, especially high temperature use function. Selection should give full play to its advantages, and from the furnace structure, masonry and protection to overcome its shortcomings.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Silicon Nitride-Carborundum Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords