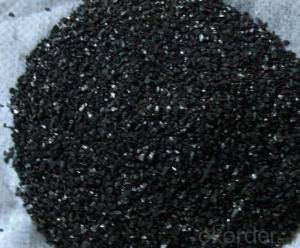

silicon carbide for steel plants with 72% SIC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Introduction

1. Silicon carbon can be used as metallurgical deoxidizer and high temperature resistant materials in smelting.

2. It can also be used as abrasive materials,which can be used to make abrasive tools,such as grinding wheels, oilstones, grinding head and so on.

2. Features

Silicon carbon is a new kind of reinforced steel-making deoxidizing agent and ideal thermal insulating agent.it is used for deoxidizing. The usage dose is 1-4kg/t can make electricity consumption to reduce 15-20kw/h and time to reduce 15-20min per furnace to raise productivity rate to 8-10%.We would like to advise you to use this cargo

With high quality, reasonable price and timely delivery, our products have been export to many foreign countries and areas, such as Japan, and other countires. our company has got praise in both domestic and foreign markets.we have been the trusted and preferred supplier to the mineral&chemical products and the market share is growing rapidly and firmly. Warmly welcome all friends from domestic and abroad to cooperate with us. It is better and better in this industry. We strongly advise your kind side to use this cargo

3. Specifications:

Grade | Sic% | FreeC% | Si+SiO2% | Fe2O3 | MgO% | H2O% |

Sic75 | 75±4 | 2.5±1 | 17±2 | 3 | 0.16 | <5< span=""> |

Sic65 | 65±4 | 4.5±1 | 23±2 | 4 | 0.12 | <5< span=""> |

Sic55 | 55±4 | 4.8±1.5 | 28±3 | 5±2 | 0.1 | <5< span=""> |

Sic45 | 45±4 | 5±2 | 31±3 | 7±2 | 0.1 | <5< span=""> |

4. FAQ:

(1) Large melting furnace, longer melting time, lead to more crystallization, bigger crystals, higher purity and less impurities.

(2) Good hardness, longer life.

(3) Chemical washed and water washed good cleanness.

(4) Special treated products get higher purity, better toughness, and better grinding effect.

1.Sample for free for your test.

2.Provide professional product consultation.

3.Offer competitive price.

4.Have precise quality control department.

5.Taking photos during the production and shipment, send the photos to customers;

6. Documents Department, to serve customer professionally.

7.Always think of the customers and make the add-value.

5. Pictures

- Q:What raw materials to produce charcoal

- Activated carbon: activated carbon can be said to be deep processing of charcoal is mainly produced in southern China, Fujian and Zhejiang area, he is to use charcoal, zinc chloride, phosphoric acid, potassium hydroxide and dolomite, chemical activation, rinsing, drying and grinding processing, the production process of water pollution is serious, production is restricted by the state.Mechanism of carbon: sawdust as raw material, the process is mainly the sawdust by machine high temperature, high pressure molding, and then into the carbonization furnace carbonization. The whole production process does not need to add any additives, belong to the category of environmental protection products. In the market, the main hexagon center is empty and there are two shapes in the center of the square. The mechanism of carbon as a traditional charcoal (traditional charcoal: trees as raw material, sintering, is a kind of destruction of resources industry has now been forbidden by the state) alternative products, it has high calorific value, burning a long time, do not smoke, do not send explosion, environmental protection and many other advantages.

- Q:Charcoal ash can do what you can do with it? emergency

- The main component of charcoal ash is potassium carbonate, which is a strong base weak acid salt, which produces OH- ions in water. Charcoal ash is widely used in rural areas. Charcoal ash is mainly composed of K2CO3. Its main function is:

- Q:What is the bulk density of activated carbon?

- In addition to activated carbon carbon, also contains two kinds of admixtures: one is the combination of chemical elements, mainly hydrogen and oxygen, these elements are due to incomplete carbonization and the residue in the carbon, or in the process of activation, non carbon and activated carbon surface chemical foreign combination, such as the use of water vapor when activated, the surface of the active carbon is oxidized or water vapor oxidation; another kind of admixture is ash, it is part of the inorganic carbon in ash; activated carbon is easy to cause two pollution.

- Q:What is the use of activated carbon

- Adsorption of formaldehyde adsorption home decoration. It is characterized by physical adsorption, adsorption, not easy to cause two pollution.

- Q:Coking plant? In addition to the processing of raw coal? Thank you

- Coal has been the dominant position in the energy production and consumption structure in china. With the development of modern science and technology and the application of new technology and new methods, the use and comprehensive utilization of coal will be more and more important

- Q:Anthracite is what kind of indicators?

- Great landlord, if my answer is helpful to you, please be sure to adopt "Oh! Thank you for your cooperation!

- Q:Powdered activated carbon and globular activated carbon which is good

- Shape does not represent the performance of activated carbon, because the activated carbon industry is not the same as the number of activated carbon has a special shape requirements!

- Q:How to classify activated carbon

- Activated carbon more to go, always have a science and technology content is better! I heard that there is a recent net titanium puriti technology, decomposition of formaldehyde

- Q:What is the smell of charcoal burning

- Similar to barbecue flavor, but generally refers to smokeless carbon, so the taste is less than barbecue flavor

- Q:How to solve the problem of coal spontaneous combustion

- Coal in the process of piling up spontaneous combustion occurs frequently, this is because the coal at room temperature will also be slow oxidation of oxygen in the air. Oxidation at the same time have a certain amount of heat, if the heat can not be dissipated, the heat in the coal heap together, temperature will rise, temperature and accelerate the oxidation of coal, when the temperature is higher than 60 DEG C when the coal temperature rises rapidly, if not timely treatment, it will cause a fire, this is the pile of coal only by self oxidation without external fire caused by the "spontaneous combustion" phenomenon. Prone to oxidation of lignite and long flame coal is more prone to spontaneous combustion".

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

silicon carbide for steel plants with 72% SIC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products