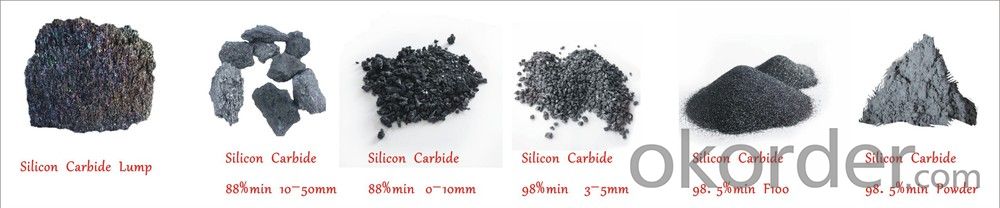

Silicon Carbide 88% 90% 0-10mm Metalllurgical Grade silicon carbide

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Brand Name: | cnbm | Model Number: | LF-SIC |

| Material: | SiC | Usage: | Abrasives, Advanced Ceramics, Refracotry, Metallurgical | Abrasive Grain Sizes: | Powder, Grain, Lump |

| Name: | Silicon Carbide | Sample: | For Freight | SiC content: | 85% 88% 90% 98.5% 99% |

| MSDS: | Available | DGM: | Available | Bulk Density: | 1.38-1.70 g/cm3 |

| Grain Size: | F12-F8000 JIS standard, 0-1,1-10,0-10mm | Moh's Hardness: | 9.5 | Original: | Henan, China (mainland) |

Packaging & Delivery

| Packaging Details: | Silicon Carbide Powder:25kg pp bags loaded in 1 ton jumbo bags Silicon Carbide Lump: 1 ton loose in Jumbo bags. Or as customer request. |

| Delivery Detail: | 7 days after payment |

silicon carbide and green silicon carbide

Silicon Carbide

Product Description

Black Silicon Carbide is made by a precision water classification process and air flow classification using material that is produced from the reaction between high purity silica sand and petroleum coke in a resistance-type furnace. Measuring 9.0+ on the MOHS scale of hardness, silicon carbide is one of the hardest abrasives known in the industry. The inherent friability of the sharp crystalline structure assures the continuous exposure of new cutting edges, which produces a faster and cleaner cutting performance.

Our silicon carbide grains and powders can be made to your exact size, chemistry and shape specifications.

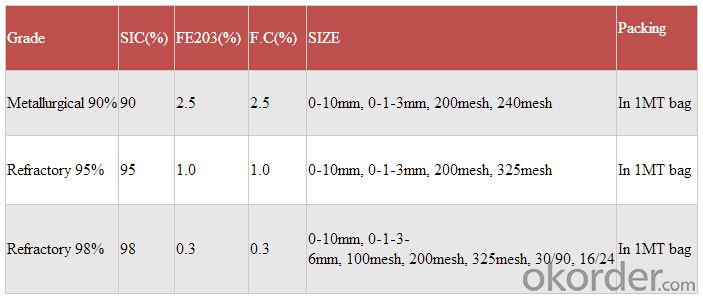

Metallurgical and Refractory Grade

Content of SiO2 | Particle Size Distribution | F.C % | Fe2O3 % | H2O % |

88% | Lump | 3 max. | 2.8 max. | 1 max. |

0-10 | 2.8 max. | |||

0-1 | 3 max. | |||

1-3 | ||||

3-6 | ||||

100F | 2.8 max. | 2.8 max. | ||

200F | 2.8 max. | 2.8 max. | ||

240F | 3 max. | 3 max. | ||

325F |

- Q:How long is the fire endurance of Grade A fire resisting shutter

- The fire endurance of Grade A fire resisting shutter is not lower than 1.20h. Use fire resisting shutter as fire?compartment separation in places where it is difficult to set firewall. When fire resisting shutter whose unexposed surface temperature rise is used as judging condition of fire endurance is used, its fire endurance should not be lower than 3h. When fire resisting shutter whose unexposed surface temperature rise is used as judging condition of fire endurance is not used, individual protection of ?closed automatic water spray system shoule be set at two sides of the shutters and duration of water spray system should not be less than 3.0h.

- Q:which is better as household fireproof material ?

- If it is from the perspective of fire rating inorganic active insulation material for wall thermal, cement foam insulation board, glass beads of insulation movitrified?micro bead?thermal insulation?mortar, rock wool board, glass wool board, ect.. thermal insulation material are Class A fireproofing, polyphenyl board, extruded sheet, phenolic foam board, Polyurethane board, ect..belong to B1 level fireproofing, if it is used for external wall thermal insulation in decorative board, then rock wool board is more often used.

- Q:Could you tell me how does fire protection standard of decorative material is divided?

- Building materials can be divided into four levels according to combustion performance (non-combustible, flame retardant, flammable, flammable). According to the Code for Design on Building Fire Protection and Prevention (GBJ16-1987) (revised in 2001):, the fire risk of production or storage is divided into a, b, c, d, e classes. Divided by plate material: structure material, base layel materials and fabric; Divided by fire protecrtion type: easy to burn, difficult to burn, flame retardant, incombustible material. Material has no fire rating, only the different from the time of combustion limit. Combustion performance grade A of commonly used adornment material: granite, marble, terrazzo, cement products, concrete products, gypsum, lime products, clay products, glass, ceramic tile, Mosaic, steel and alloy. I hope my answer can help you.

- Q:How much is refractory spraying coatings?

- This depends on whether you use the thin coatin or thick coating. Then it depends whether you use an aqueous coating or oily one. Usually thick aqueous coating is 2-3 dollars per kilogram. While the thin is six or seven dollars per kilogram. The oily coating is more than ten dollars. The prices obtained from the Internet is for reference only.

- Q:How long is the fire resistant limit for ultra thin fire retardant coating?

- According to the "code for fire protection design of tall buildings", the fire resistance time of the component is at the first level: 3 hours, beam: 2 hours, floor: 1.5 hours;if fire resistance level is level 2, the requirement for time of fire resistance component is the column: 2.5 hours, beam: 1.5 hours, floor: 1 hours. For fire resistant coating, fire resistance time for ultra-thin fire retardant coating is less than 1.5 hours. If the time exceeds 1.5 hours, thick fire resistive coating should be uesd.

- Q:What are the fire endurance requirements of class A fire resistant door ?

- The fire endurance of class A fire resistance door is 1.5H, but also depends on the product quality. The filling material of class A, B, C fire doors is the same, new fireproofing material-- perlite. The difference is their thickness. The general structure is: surface panel, fireproof?board framework (filled with perlite) fireproof?board panel. !

- Q:Is there a worker in (Jigang refractory plant)?

- Exactly, you are not in the strict sense of the refractory plant contract worker, your contract is not signed and refractory plant, your wage system, and the worker in the factory is not the same, you can not follow the normal off-duty execution system

- Q:The effect of a high content of water in liquid resin exerted on refractory material?

- For one thing, Substandard whiteness, transportation, low quality and the storage of refractory material may account for this. For another, a high content of moisture reduced the performance of refractory material. A high content of moisture is equal to buy water with same money in terms of trade settlement. Based on this, we can’t consider the super-standard water content from a single aspect, because the water content in refractory material is definitely super-standard, and another problem is particle size. Many people hold the idea that excessive amount of water content may revive its original performance, but it tends to have influenced the quality of refractory material.

- Q:How to divided the grade of external wall thermal insulation materials?

- Synthesized the three versions of GB8624 (1997,2006,2011), external wall thermal insulation fire?rating can be basically divided into: A1, A2, B1, B2, B3 and other levels. There are many technical indicators to make specific division, but I partly cannot report for a while, because it is very professional and technical. Please contact Qingdao Shanfang Instrument Co., LTD for details, they specialized in the external wall thermal insulation materials fire?rating test

- Q:What's the heat conductivity coefficient of fire-resistant material?

- 5~5 (Unit: W·m-1·K-1). The symbols are λ or K. Thermal conductivity and material properties Thermal insulation material generally is 0, and is related to organizational structure and working temperature. Thermal conductivity of the material refers to the heat transferred from from one plane to another plane in 1 seconds. Generally the thermal conductivity of fire-resistant material is 1. The larger the value is, the stronger the thermal conduction performance is. If the temperature of two planses differes for 1K, then the thermal conductivity is 03~1. The plane cover 1square meter.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Silicon Carbide 88% 90% 0-10mm Metalllurgical Grade silicon carbide

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords