Silica Ceramic Foam Filter with Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Foam Filter

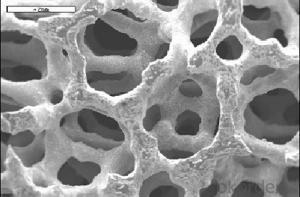

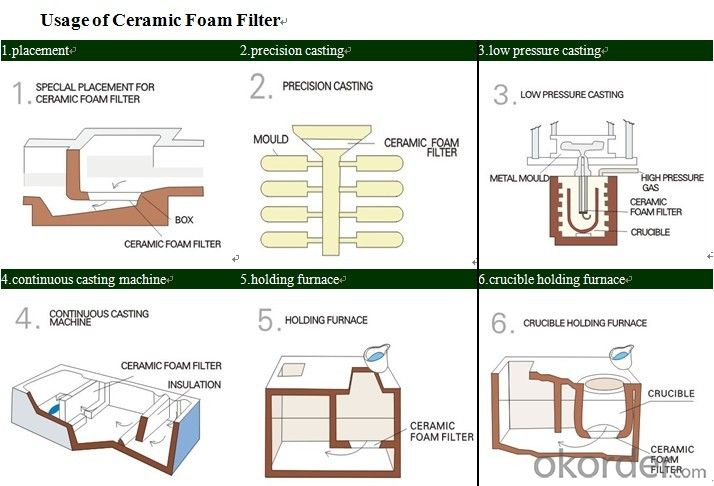

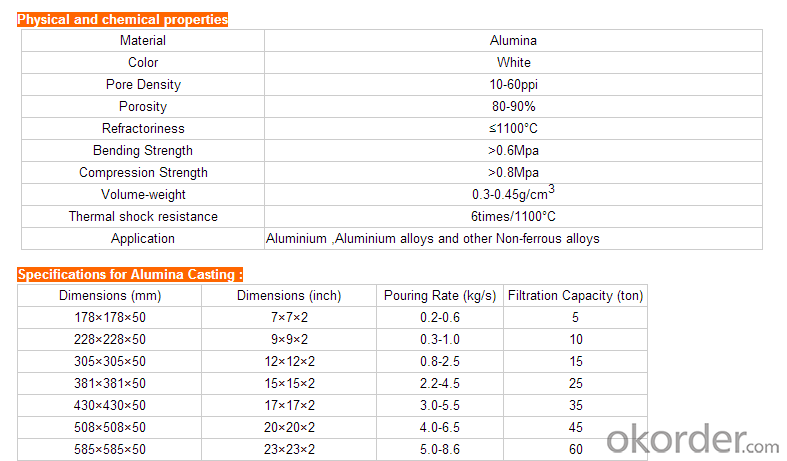

Foam Ceramic are mainly used for filtration of aluminium and aluminium alloys in foundries and cast houses . With their excellent thermal shock resistance and corrosion resistance from molten aluminum, they can effectively eliminate inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Silicon carbide ceramic foam filters are mainly designed to improve the quality of iron castings. The filter can effectively remove non-metallic inclusions including slag and dross from the molten metal stream.Additionally, they aid in reducing turbulence in the gating system.

SIC ceramic foam filter's outstanding thermal shock resWe have a factory manufacturing foam ceramic filter, Main products include:

1. CFA (Alumina Foam Ceramic Filter)

2. CFS (Silicon Carbide Foam Ceramic Filter)

3. CFZ (Zirconia Foam Ceramic Filter)

4. CFM (Magnesia Foam Ceramic Filter)

5. Honeycomb Ceramic Filter

Product Applications:

Zirconia ceramic foam filters apply to purge and filter solution of carbon steel, steel alloy and stainless steel.

Product Advantages:

Reduce imparities of the castings

Improve casting quality rate

Reduce casting internal re-oxidation defects

Reduce the surface defects after machining of the castings

Precise Dimension Tolerance

High Mechanical Strength

Chemical Stability and Corrosion-resistance for molten aluminum.

Main Product Features:

We have a factory manufacturing foam ceramic filter, Main products include:

1. CFA (Alumina Foam Ceramic Filter)

2. CFS (Silicon Carbide Foam Ceramic Filter)

3. CFZ (Zirconia Foam Ceramic Filter)

4. CFM (Magnesia Foam Ceramic Filter)

5. Honeycomb Ceramic Filter

Product Specifications:

FAQ:

1. How you can control your quality?

For each production processing, we have complete QC system for the chemical composition

and Physical properties. After production, all the goods will be tested, and the quality certificate

will be shipped along with goods.

2. What's your delivery time?

It usually needs about 20days- 45 days after receiving the deposit.

3. Do you provide free samples?

Yes, we can provide a free sample for testing, If we have sample in stock,

The quantity based on the material type, The buyer should bear all the shipping costs.

4. What's your payment terms?

We can accept 30% deposit, 70% balance before shipment for ordrs over $ 2000.

Product Picture

- Q:What filter material are placed in the aquarium filter?

- Generally let off the filter cotton and ceramic rings, there are biochemical balls, coral bone, stone, activated carbon and so onConditional: filter cotton, ceramic ring, biochemical ball, coral bone, stone, activated carbon

- Q:Ceramic filter fineness thin mud suction is not what to do more

- With ceramic filter to treat pulp dehydration, the particle size is too large, the particles are easy to precipitate, the particle size is too small, too much mud, then the water content of the filter cake will increase, and the life of the ceramic filter plate will be reduced.

- Q:Does the ceramic factory use hydrochloric acid?

- In order to avoid the possibility of plugging, ceramic filter plates with suitable aperture range of different manufacturers can be selected.

- Q:The ceramic filter plate is broken. What will happen to the vacuum pump?

- If it is found that the ceramic plate is broken, it should stop in time to replace the broken ceramic plate. Ceramic filter is produced by vacuum suction vacuum pump to the pulp in the water through the ceramic plate away, the surface aperture ceramic plate for several microns, so it can intercept the cake on the ceramic plate on the surface, if the ceramic plate is broken, a hole is a few millimeters, when the vacuum suction pump when they go together along with the pulp pump.

- Q:The efficiency of ceramic filter is low. What's wrong with it?

- CleanThe cleaning of ceramic filter is divided into two parts: reverse flush cleaning (also useful gas) and combined cleaning. The purpose of cleaning is to discharge the particles from the hole to the ceramic filter board.Anti flushing and cleaning water filter after direct visual pressure can, generally between 0.08--0.12MPa, such as less than 0.05MPa, while the poor flushing effect without even washing effect, resulting in blocking accumulation eventually led to the ceramic filter plate hole plugging scrap. Replacing the filter element in time and ensuring the water pressure before filtration can provide stable backwashing water pressure.Combined cleaning by ultrasonic vibration, nitrate dissolution method for maximum remove blockage of backwash rushed out, the general ceramic filter every 8 hours of continuous work should stop cleaning 1 hours, such as the use of the old plate or the suction effect is poor, can strengthen cleaning (such as shorten the cleaning period, prolong the period of cleaning, increase the amount of nitric acid etc.).

- Q:What's the acid of the ceramic filter plate?

- General ceramic filter running for eight hours or so, you need to stop for joint cleaning, general cleaning at an hour or so. When washing together, there is acid washing, usually concentrated nitric acid. The purpose is to dissolve the pores in the ceramic filter plate through nitric acid.

- Q:Ceramic filter cleaning, sulfuric acid cleaning

- Ceramic filter medium is ceramic, ceramic generally resistant to strong acid, alkali, cleaning, it is best to use nitric acid, hydrochloric acid next, not recommended to use sulfuric acid.

- Q:What's the reason for high water content in filtration copper concentrate?

- Can the cleaning of ceramic plate meet the requirement?Such as cleaning of ceramic plate is not up to the requirements, plugging holes will increase the risk of ceramic plate, ceramic plate plug serious suction effect will become worse (filter cake moisture content increased, cake thickness reduction), cleaning of ceramic plate refers to washing and cleaning.Backwash to ensure that the water filter filter water pressure in the 0.1MPa or so, at least not less than 0.07MPa or less, it is necessary to consider before the filter water pressure is low or water filter element needs to be replaced.Joint cleaning to ensure that the ultrasonic can be no trouble, every time cleaning the amount of nitric acid up to standard. If the filtration effect is not ideal, the cleaning cycle can be washed from 45--60 every 8 hours, changed to 6--7 hours and cleaned for more than 1 hours.

- Q:Microporous ceramic filter plate cleaning

- In order to avoid the possibility of plugging, ceramic filter plates with suitable aperture range of different manufacturers can be selected.

- Q:Influence factors of ceramic filter

- Ceramic filter board, also known as ceramic filter membrane, ceramic plate, ceramic plate, filter plate, etc., is made of corundum, silicon carbide and other special process made of new filter media. At present, as the core component of the ceramic filter, ceramic filter plate has been widely used in solid-liquid separation of iron concentrate, zinc concentrate, sulfur concentrate, copper concentrate, nickel concentrate, molybdenum concentrate, lead concentrate, tungsten concentrate, manganese ore, vanadium ore, aluminum ore, gold ore, non-metallic mine Ore Concentrate Dewatering and coal, chemical industry, papermaking, pharmaceutical, chemical, food, environmental protection and other industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Silica Ceramic Foam Filter with Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords