Silica Brick For Glass Furnace with Solidity Stable of Capacity

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 10000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

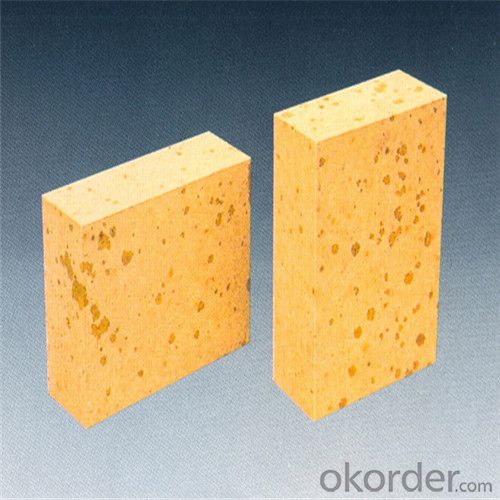

General Information of Silica Brick

CMAX silica brick is a kind of acid refractory product which is mainly made of tridymite and cristobalite, and a small amount of quartz and vitreous..

Image of Silica Brick

Feature of Silica Brick

Superior resistance to acids (including oxidizing)

Resistance to chlorine

Resistance to thermal shock and pressure changes

Low thermal and chemical expansion

Application of Silica Brick

Coke Oven

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

- Q:The chemical composition of silica brick and its physicochemical index?

- Brick refers to the refractory products in more than 93% of the content of SiO2

- Q:What are the main constituents of refractory bricks?

- Clay brick and clay brick are mainly composed of mullite (25% ~ 50%), glass phase (25% ~ 60%) and square quartz and quartz (up to 30%). Usually with hard clay as raw material, pre calcined mature material, and then with soft clay, semi dry or plastic molding, the temperature at 1300~1400 C fired clay brick products. Can also be added a small amount of water, glass, cement and other binders to make non burning products and amorphous materials. It is a refractory brick commonly used in blast furnaces, hot blast furnaces, heating furnaces, power boilers, lime kilns, rotary kilns, ceramics and refractory bricks.

- Q:Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.

- Q:Because of the recent relates to this industry, by way of learning to name for all raw materials, I hope knowledgeable friends exhibitions, thank you.

- The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q:Common bond brick?

- Manufacturing for silica brick binder hi-li sulfate pulp waste liquid and lime milk. When lime milk is used as a bond, it acts as a plasticizer. To increase the strength of lime brick in the drying process, as mineralizer in the firing, promote the transformation of quartz.

- Q:Why is the new trend of the high thermal conductivity of silica brick

- The use of high thermal conductivity of silica brick, reducing coke fuel consumption, reduce emissions of pollutants such as NOx, with considerable economic benefits and social benefits, is the future direction of the new technology of using coke oven refractory.

- Q:How to improve the thermal conductivity of the coke silicabrick rate?

- The content of SiO2 is 98.23% crystalline silica as raw material, with sulfite pulp liquid as binder, millscale and lime as mineralizer, by Jin Hongshi (TiO2) as additive, can improve the rate of thermal conductivity of silica brick for coke oven. When the rutile content is 1.5%, the coefficient of thermal conductivity of silica brick for coke oven is 2.66W/ (m.k).

- Q:Why will expand when heated brick

- Because the production of raw materials are silica brick, brick with SiO2 content of not less than 95% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system

- Q:The hot blast stove when the temperature did not rise against the brick interface decreased

- How to keep the brick masonry temperature not lower than 600 DEG C, while the exhaust temperature is not higher than 400 DEG C.

- Q:Why in the production of the brick to detect the volume density

- Density is the property of material, different density of materials, density of the same kind of material is not up to standard, affecting performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Silica Brick For Glass Furnace with Solidity Stable of Capacity

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 10000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords