Silane Cross-linkable Low Smoke Zero Halogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Halogen Free flame retardant:

1. competitive price

2. 30 years of experience

3. stable quality

4. customized product

Halogen Free flame retardant:

1. Applications and cable specifications:

General type. Used as cross-likable low smoke halogen free insulation and jacket for electronic wires, cotton coverd wire for construction. Work temperature: -40 to 125 degree C .

2. Description:

Silane crosslinkable low smoke halogen free POE compound, based on POE resin, is produced and pelletized by special technology, adding flame retardant, initiator, crosslinking agent and other special additives. This compound is composed of A materials and B materials, when it is used, please mix the A and B in the proportion of 97:3. This compound has advantage of excellent properties, processing easily, and excellent physical properties, meeting JB/T 10436-2004 standard.

3. Processing:

Equipment: it is recommended that this compound should be processed by professional screw for halogen free compound, with compression ratio of 1.2 to 1.5 (L:D should be 25 to 18). If you use PVC extruder, the speed should be lower and focus on cooling.

The following temperature(degree C) profile of extruder is recommended (temperature here is only for reference, and it will be different according to different extruder and temperature controlling equipment):

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature | 110 | 140 | 160 | 160 | 165 | 170 |

Method of application:

(1) When you use this product, please mix A and B before put into the hopper. If you need color, the cable factory can use the polyvinylene masterbatch. The material should be used up after it opened in 8 hours and the rest can be resealed and usable within 24 hours.

(2) The extruder should be cleaned with PVC material after stopping, (It is preferable if you can take apart the screws to clean.)

(3) The silane crosslinkable LSZH compound should not be stayed in the extruder for a long time .If it stayed for long time, it will pre-crosslink after open the machine, which will make lumps in the surface of cable. It need to be discharged all the pre cross-linker, and then produce the cable properly.

(4) To ensure the safety and fully of the cross-linking, when immersed the compound into the hot water or steam, please calculate the cross-linking time based on the terms of more than 85℃, 8h/mm thickness cross-linking speed.

(5) At room temperature, the degree of crosslinking can also meet requirements after 7-10 days. The specific time can be different according to the temperature and humidity.

Note:

(1) Transportation: avoid direct sunlight and weathering and machine damage

(2) Convey: discharge softly, put off softly, avoid from the bursting by the stressed with the aluminum-plastic Bag.

(3) Storage: it can not be landing stack. It should be put on the pallet in the clean dry storage.

(4) Keep dry: When the material used, it must not be contained the outer water. Otherwise, it will seriously pre-crosslink.

(5) Quality guarantee period: 6 months after manufacturing.

4. Storage and transport:

Packaging:25kg/bag, Aluminum foil and PE film bag inside, and Kraft bag outside.

Storage and transport: Avoiding in direct sunlight and weathering. The storage should be clean, cool, dry, and ventilated.

5. Properties:

NO. | Item | Unit | GDW125A | GDW125C | GDW125H | |||

Standard | Typical | Standard | Typical | Standard | Typical | |||

1 | Density | g/cm3 | — | 1.44 | — | 1.38 | — | 1.43 |

2 | Tensile strength | MPa | ≥10 | 14.1 | ≥10 | 11.0 | ≥10 | 13.1 |

3 | Elongation at break | % | ≥150 | 240 | ≥150 | 230 | ≥150 | 230 |

4 | Hardness | Shore A | — | 97 | — | 91 | — | 97 |

5 | Thermal aging |

|

|

|

|

|

|

|

Condition: temperature | 158℃ |

|

|

|

|

|

| |

Time | 168h |

|

|

|

|

|

| |

TS retention | % | ≤±30 | -10 | ≤±30 | -12 | ≤±30 | -10 | |

EB retention | % | ≤±30 | -13 | ≤±30 | -10 | ≤±30 | -8 | |

6 | Thermal prolongation 200℃,0.2MPa,15min |

|

|

|

|

|

|

|

Elongation under load | % | ≤175 | 70 | ≤175 | 80 | ≤175 | 65 | |

Permanent deformation | % | ≤15 | 0 | ≤15 | 0 | ≤15 | 0 | |

7 | Volume Resistivity, at 20 degree C | Ω·m | ≥1.0×1012 | 2.3×1013 | ≥1.0×1012 | 2.0×1013 | ≥1.0×1012 | 2.1×1013 |

8 | Dielectric strength | MV/m | ≥20 | 28 | ≥20 | 28 | ≥20 | 29 |

9 | Resistance to thermal stress crack | h | ≥96 | pass | ≥96 | pass | ≥96 | pass |

10 | Resistance to environmental stress crack | h | ≥96 | pass | ≥96 | pass | ≥96 | pass |

11 | Oxygen Index |

| ≥30 | 36 | ≥30 | 30 | ≥30 | 36 |

12 | Smoke density flaming |

| ≤100 | 50 | ≤100 | 60 | ≤100 | 50 |

Non flaming |

| — | 130 | — | 150 | — | 120 | |

13 | Burst Size of HCL | mg/g | ≤5 | 0 | ≤5 | 0 | ≤5 | 0 |

14 | PH value |

| ≥4.3 | 6.7 | ≥4.3 | 6.5 | ≥4.3 | 6.3 |

15 | Conductivity | μS/mm | ≤10 | 0.8 | ≤10 | 0.6 | ≤10 | 0.9 |

16 | Toxicity Index |

| ≤3 | 1.2 | ≤5 | 1.3 | ≤5 | 1.3 |

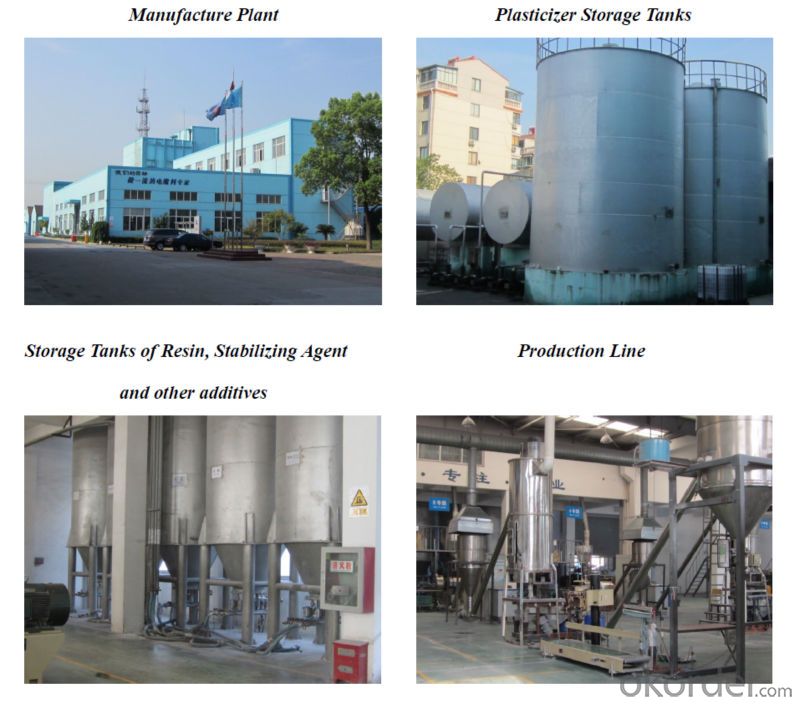

6. Company

- Q:What material do you need for plastic film? Do you use this material?

- Or LDPE (high pressure polyethylene). Or a mixture of the two. The bags made of two materials each have their own characteristics, and are chosen according to the purpose and performance of the products. Polyethylene is petrochemical products, prices vary according to crude oil and market conditions every day, at present LDPE (high pressure polyethylene) offer at 13500 yuan. HDPE (low pressure polyethylene) at 11000 yuan up and down.

- Q:How many kinds of raw materials are produced by wrapping plastic film?

- Plastic film raw materials are: PVC, polyethylene, polypropylene, polystyrene and other resins.Commonly used to bundle packaging is LLDPE stretch wrap film, applicable to a variety of logistics packaging, packaging industry bundled! I can see it in Ming Bao. Yes, please!

- Q:What are the raw materials made of modified plastics?

- In order to reduce costs, improve performance and meet different needs, plastics are often modified to suit a variety of practical requirements. Commonly used methods are mainly:1. filling modification, adding a certain amount of filler in plastic is an important way to reduce plastic prices and improve performance. Such as phenolic resin filled with wood and paper made of bakelite practical material, overcomes the weakness of crisp.2. blends of two or more polymers with similar properties and two or more polymers are blended in a certain proportion to make polymer blends.3. copolymerization of two or more than two kinds of monomer polymerization of a copolymer of ethylene propylene rubber, such as copolymerization of ethylene and propylene has a good elasticity; acrylonitrile, butadiene and styrene copolymer obtained with ABS resin.

- Q:Commonly used plastic products, which are made of what raw materials, which can be recycled, I hope to get a professional answer in detail

- In daily life, we can directly contact or perceived plastic, is the most common plastics routine, mainly include five categories: PE (polyethylene), PP (polypropylene), ABS (acrylonitrile butadiene styrene plastic), PVC (polyvinyl chloride), PS (polystyrene), these five categories accounted for plastics the vast majority of plastic raw materials used, the basic can be classified as special plastic varieties, such as: PPS (PPS), PPO (polyphenylene ether), PA (polyamide), PC (polycarbonate), POM (POM), they are in daily life in the small amount of the product, mainly used in industry and engineering the national defense science and technology and other high-end fields, such as automotive, aerospace, construction, communications and other fields.

- Q:Is plastic bucket and plastic bottle the same raw material?

- When the number of the triangle in the bottom of the barrel is "1", the main component of this kind of plastic bucket is polyethylene terephthalate (polyester), which is often called PET. The melting point of this kind of plastic barrel is high, but the heat resistance can only reach 70 degrees centigrade, and it is easy to deform. When the temperature of the plastic barrel is higher than that of the plastic bucket, the possibility of dissolving harmful substances in the plastic barrel is increased, and the material such as wine, oil and the like can be easily twisted and contracted. As China has traditionally been thrifty, people tend to reuse plastic buckets. However, this kind of plastic barrels of repeated use, may release carcinogenic DEHP, if such liquid plastic barrel by people drinking, will may be suffering from cancer, also has toxicity to male testis, its harm should not be overlooked.

- Q:What raw material produces the plastic to the human body not to harm, to the environment does not have the pollution?

- Starch plastics containing starch in more than 90%, add other components also can be completely degraded, there are Japan Sumitomo Business Corporation, American Wamer-Lamber company, Italy Ferrizz company claims of success starchier in 90% to 100% of full starch plastics, in (January ~ 1) completely biodegradable without leaving any trace, no pollution, can be used in the manufacture of various containers, bottles, films and garbage bags etc. all starch plastics production principle is that the starch molecular allostent anddisorderly change formed with thermoplastic starch resin, also known as the thermoplastic starch plastics. The molding process can be used in traditional plastic processing equipment. With starch as the potential advantages of development of bio degradable plastics raw materials: starch has biodegradability completely in various environments; plastic in the degradation of starch molecules or after ashing, the formation of two oxygen Carbon gas, without soil or air poison; take appropriate technology to make starch thermoplastic after mechanical properties can reach for manufacturing plastic material; starch is a renewable resource, inexhaustible, pioneering starch utilization is conducive to rural economic development. That is, starch plastics production in China of vast the majority of starch filled plastics, is added in a certain proportion of polymer materials in non biodegradable starch, resulting in the collapse of material physical property through biodegradation of starch, prompted a large number of end groups that exposed to oxidative degradation, but the rest of the "collapse" after the PE, PVC and so on are not always possible degradation the residue in soil, of course, days and months multiplying will cause pollution, so the foreign ownership for such products will be eliminated.

- Q:What is the disposable transparent plastic cup?

- PMMA: commonly known as acrylic, transparent material, its surface hardness is slightly lower, easy to wipe flowers. It is suitable for making transparent insulation parts and general strength parts

- Q:What kind of material is the raw material of plastic pipes?

- Plastic pipe raw material is plastic particles, according to the pipeline production processing performance requirements, with the different requirements of finished products, there are different manufacturers grades, grades and performance differences.

- Q:What is the difference between PP raw material and modified PP?

- Sort:(1) according to the characteristics of resin when heating and cooling, classification: 1. Thermosetting plastics, two, thermoplastics(2) according to the use of plastics classification: general plastic, engineering plastics, special plastic raw materialsModified PPThe concept of modified plastic PP, refers to the base of the general plastics and engineering plastics, after filling, blending and enhancement processing method of modification, improve the performance of flame retardant plastic products, strength, impact resistance, toughness.Classification: PP modified plastic products are mainly a variety of flame retardant resins, toughening resin, plastic alloy, functional masterbatch etc..

- Q:What plastic materials need to be dried for injection molding products?.. How much is the temperature?

- Plastic particles, such as water, are evaporated in the pre heating process of the injection molding machine and then condensed in the cooling molding process, which acts as (Yin Si) in the product and affects the quality of the product.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Silane Cross-linkable Low Smoke Zero Halogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products