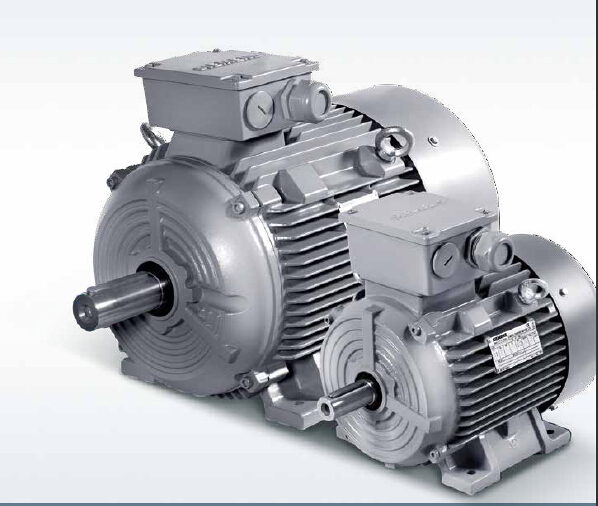

Siemens ILE0001 Series AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:DC motors vs AC Motors?

- What is your question?

- Q:How to use single-chip microcomputer to control AC motor 65KTYZ, what should be used to control the chip? Please give expert advice. It is better to give access to each interface.

- With two relays (or IGBT what) do isolation, change any of the two lines after the state of the line on the line. For example, when the A-C-B is turned on, the A-B-C is switched on, and if it is reversed, the drive relay (or IGBT) becomes a reverse.

- Q:How does it go from off to one direction to off to the other direction? How does the switch work?

- Usually a two direction motors are three phase motors thou it can be single phase motor but with three phase motor its easy to control. This if it works on AC currant. It also can be DC that is easer to control. 3 phases AC motor you can reverse the direction of rotation by switching two phases instead of U V W you have to make it U W V or any other combination. And it will reverse you can achieve this with a switch to give an order to a contactor to do the switching. Note that you may need a time delay to make the switching to have the motor at complete stop before reversing. Single-phase motor is very complicated process I think no one do this. A DC motor is easy you just switch the + to – and the – to + then it will reverse this can be achieved by a change over switch. Also you can use the change over switch for the 3-phase motor.

- Q:Why can single-phase AC motors be controlled by voltage?

- Simply put, after the voltage is lowered, if the rotor spins at its original speed, the stator gets a very small current. The electromagnetic torque decrease under the same load torque under the action of slip increase speed decreased, resulting in decreased speed reflected impedance decreases according to the size of the formation of a low impedance voltage and current speed speed balance, therefore maintained at a low speed.

- Q:I know it has something to do with the capacitor and a less than 180 degree phase shift. But thats all I know.

- To reverse rotation of a single phase motor,interchange connection of the starting winding. The starting winding is one with a terminal connected to a start capacitor.Disconnect the other end that normally is connected to the running winding or common.Transfer connection of this terminal to the capacitor and the original terminal connected to the capacitor connect to the common winding.

- Q:Is the permanent magnet synchronous linear motor AC motor or direct current motor?

- Permanent magnet synchronous motor (PMSM) is usually referred to as brushless DC motor with back electromotive force, trapezoidal wave and armature current as square wave. The back electromotive force and armature current are both sine waves, which are called permanent magnet synchronous motors.

- Q:Can any AC motor 220 and 380V control positive inversion? What are the conditions?

- There are commonly used reverse switch control (Figure 1), switching control (Figure 2) and AC contactor controlSingle-phase series motor (portable electric tools) can be 2 lines of stator winding connected between the carbon brush can brush with control of the motor is reverse.Single-phase shaded pole motor with self shading coil can not change the position of the short circuit and embedded in the stator slots, the motor is not reversed.

- Q:will it affect the defroster or heater if i cut the ac belt?

- I would suspect that the belt that controls the AC compressor is also controlling the power steering pump and possibly alternator. You would need to make sure the compressor has an indiviual drive belt. It would be easier to remove the fuse for the A/C system which should allow you to still have the use of the heater, etc.

- Q:Can anyone give me the torque equations for AC synchronous motor and generator

- Your question is somewhat complicated but adding a load will lessen pace. The intention of a process is to run loaded on the preferred speed. One factor concerning the vehicle alternator or some other synchronous generator is that a excitation present is required so within the case of the auto alternator, it wants to be linked to a battery to work. Also in lots of instances the ignition lamp is also a part of the circuit and must be linked for it to work.

- Q:What's the difference between a three-phase asynchronous motor and an ordinary one?

- The three-phase asynchronous motor cooling fan is fixed on the shaft of the motor of the same, and the rotation speed of the motor, low frequency operation, low speed fan also, cooling capacity is greatly decreased, the heat generated from the motor, which will burn the motor. And the structure of frequency conversion motor and the ability to withstand voltage have been specially designed to meet the requirements of high speed and high harmonics.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Siemens ILE0001 Series AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords