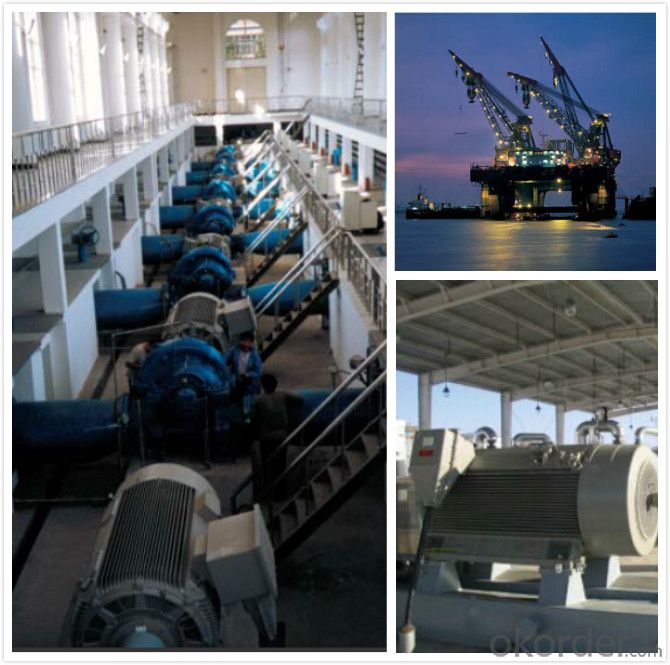

Siemens High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| part name | brand | model | Voltage | protection | cooling | |

| motor | Siemens | 1LA8 | 1PQ8 | 400V,690V,2.3KV,4.16KV,6KV | IP55 | IC411 (1LA8,1LA4) |

| IC416 (1PQ8,1PQ4) | ||||||

- Q:what should i do to make it really fast?use more magnets? how do i reduce friction?how many coils?thanks!!!!

- Welcome to the the World of Electric Motors. How to Builda 2 Amp Motor, a step at a time. Coiling, position of Magnet (Type of Magnets), choice of Bushing and bearings, all play a integral part of making either a High torque or in this case RPM motor. Assuming that you are operating a DC Motor, (AC Motor, don't usually use magnets, but there are some out there) Start with Basic Design Link 1. - Answer you question about number of magnet (More accurately the Magnet strength) - And the Number of Coils Request for Speed Link 2. Summary For Speed, usually requires a lot of coils, generating a rapidly changing field, expect a few armature and alot of sections of magnets. Note 2 Ampere is al lot of current, and can easily harm any careless person. Check several time, visually and with the proper equipment before energizing the equipment. Friction reduction is a complete science by itself. If it is a School project, consider Dry type of Lub such as Graphite Carbon. As the running duration is short. (tens of minutes runs, with long period of down time that allow inspection) If it need a longer running time is expect, consider commercial grade stuff, such as Air bearings.

- Q:Everything in the furnace and AC runs but no air blows. I've been told the motor needs replaced and will cost $2300! They never checked the outside unit at all.

- If the motor needs replaced that sounds a little steep. Can you tell if the blower is running? If the blower motor is bad there is really no need to check the outdoor until it is fixed. If it is not working then it either is bad or it's not getting power to it.

- Q:So, my old blower motor started smoking, and sparking, I took it in, and bought a new one, the guy also sold me a new capacator with it, and hooked it up for me... BUT I'm confused which wires go where. I took pictures..

- The orange wire connected to the old capacitor can be removed and connected to the white wire. .Connect the black wire to the relay and the two capacitor wires as the guy that sold it too you had it.

- Q:How can a DC motor be changed into a three-phase AC motor with good performance?

- DC motor is changed to three-phase AC motor:Direct current motors and AC motors are generally unable to replace each other. This is because the DC motor and AC motor of the external characteristics of comparison, there are still very different, compare the relevant information will know.

- Q:Why are electric hair dryers divided into direct current motors and alternating current motors? What are their differences?

- AC motor: wind, make the sound small, more durable, hot and cold big difference, large volume, stable current to prevent overvoltage protection AC fever dead machine, most hair dryer is now all communication, have built-in motor protection diode

- Q:what happens if ac is fed to a dc motor?

- Depends. If it is what is known as a universal motor, the motor will start and run. However, most motors are optimized to run on either AC OR DC and so will only work satisfactorily on the system it is designed for.

- Q:Causes of insulation breakdown in AC motor voltage withstand test

- For various reasons, the insulation parts are weak in AC motor, and the breakdown of the weak parts of the insulation in the withstand voltage test

- Q:simple question all i want to know is what a ac motor is and how it functions?

- An AC motor is an electric motor that runs on alternating current, used in most homes and businesses. There are several different types, e.g .induction motor, squirrel cage, universal, 3-phase. Try wikipedia. The basic principle is electric coils generating magnetic fields which push on other coils to make them turn.

- Q:How do I change the speed of the motor?

- The speed and frequency of motor poles, polar slip on changing the motor starting capacitor, the direction of rotation of the motor can be changed by a pair of pole motor each phase is about more than 2800 rpm, 4 pole motor is about more than 1400 rpm, 6 pole is about more than 960,.

- Q:if i have a ac battery pack connected to a motor then does the motor have to be AC or DC

- There are no AC batteries. I do not know what you mean when you write of an AC battery pack.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Siemens High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords