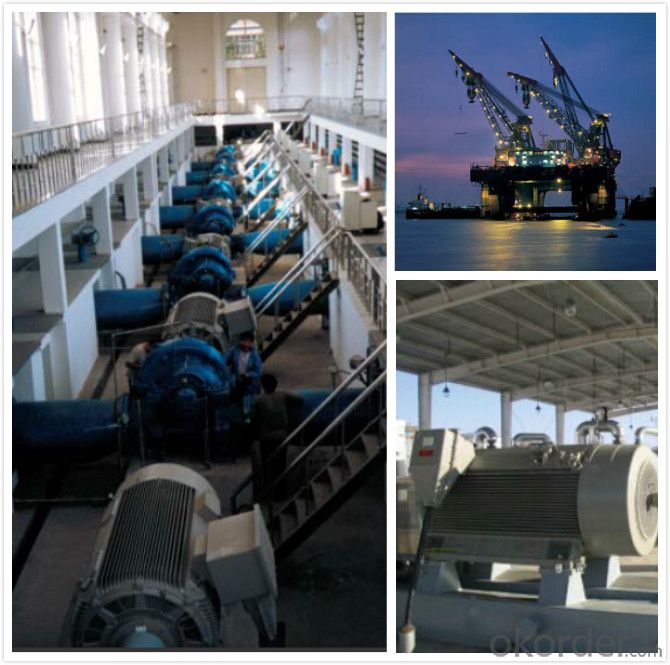

Siemens 1PQ High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| part name | brand | model | Voltage | protection | cooling | |

| motor | Siemens | 1LA8 | 1PQ8 | 400V,690V,2.3KV,4.16KV,6KV | IP55 | IC411 (1LA8,1LA4) |

| IC416 (1PQ8,1PQ4) | ||||||

- Q:Speed control method of AC motor

- The characteristics of various speed regulating devices:(1) change pole speed regulation;Advantage:No additional slip loss, high efficiency;Control circuit is simple, easy maintenance, low price;The smooth speed regulation with higher efficiency can be obtained by matching with the stator voltage regulating or electromagnetic slip clutch.Shortcoming:Stepless speed regulation without stepless speed regulation. Due to the limitation of the motor structure and manufacturing process, only 2~3 kinds of pole to rail speed regulation are usually achieved, and the speed range is quite limited.

- Q:basic difference between normal and servo motor?

- This Site Might Help You. RE: basic difference between normal and servo motor?

- Q:Why is the rotor of an AC motor neither magnetic nor can it rotate?

- The question is not entirely good.What you call an alternating current motor is an alternating current asynchronous motor, also known as an induction motor. Its working principle is: the stator current, will form a rotating magnetic field; the magnetic field and the rotor bar cutting the magnetic field; because the rotor is a closed loop, thus forming the current; so there is a movement with conductor in a magnetic field. This is the action of electromagnetic induction.

- Q:What's the difference between direct current motor and AC motor?

- A direct current motor is a magnetic field that does not move; a conductor moves in a magnetic field; an alternating current motor rotates in a magnetic field, and the conductor does not moveDC motor consists of stator winding and rotor winding of stator winding. The magnetic field is produced. When the direct current. The stator windings produce fixed polarity magnetic field. The rotor energizing force in the magnetic field. So the rotor in the magnetic field force is rotating. The DC motor structure is complicated. The cost is high.

- Q:where are ac motors used at today?

- in an ac

- Q:If the current is 45 amperes under this condition, calculate the power factor, reactive power, and reactive kilovolt-amperes

- You didn't state whether it was a 3-phase or single-phase motor. At 8.8kW input, the equivalent input horsepower HP is: 8.8kW/(.746kW/HP) = 11.8HP input equivalent. I say input equivalent because horsepower normally means mechanical output power. Around here, that would require three-phase power, so assuming it is operated at a nameplate voltage rating of 230V 3-phase, the following calculations can be made: input kW = 8.8kW (given) input kVA = 45A x .230kV x 3^(1/2) = 17.93kVA power factor PF = (input kW) / (input kVA), or PF = 8.8 kW / 17.93 kVA = 0.4908 = 49% The reactive factor RF = sin ( arccos ( PF ) ) RF = sin (arccos ( 0.4908) ) = 0.8713 = 87% Reactive power = RF * kVA = .08713 x 17.93kVA = 15.6kVAR Reactive kVA = 15.6 kVAR Check: kVAR = ( kVA^2 - kW^2 ) ^ (1/2) kVAR = ( (17.93kVA)^2 - (8.8kW)^2) ^(1/2) kVAR = 15.6 kVAR it checks.

- Q:what is the formula for torque in ac motor?

- A variable-frequency drive (also termed adjustable-frequency drive, variable-speed drive, AC drive, micro drive or inverter drive) is a type of adjustable speed drive used in electro-mechanical drive systems to control AC motor speed and torque by varying motor input frequency and voltage

- Q:What should be the resistances of 6 combinations of 3 wires of a 3 - phase AC motor connected in star configuration ?What should be the resistances of 6 combinations of 3 wires of a 3 - phase AC motor connected in delta configuration ?thanks in advance

- Whatever combination you use, typically the star is 1/3 the resistance of the delta. hth.

- Q:Every dryer motor iv ever disassembled has one...I just inherited an old radiator hot water pump motor and it has one...These are the only true AC motors i ever encounter.

- there are two windings (stator) in these types of motors. one is the starting windings and the other is the run windings. the switch in question is for the starting windings. start windings provide higher torque for the motor to start and as the motor comes up to speed. the switch opens due to the centrifugal force and allows the run windings to take over.

- Q:What advantage does an AC motor have over a DC motor?

- AC induction motor don't require brushes and are extremely rugged. These motors operate at a RPM of 120* Frequency/ pole pairs minus the slip speed. An induction motor with one pole pair will operate just below 3600 RPM ( somewhere around 3400 RPM) at a line frequency of 60 hertz. The slip speed is usually about 150 RPM or so. It varies depended on how heavily loaded the motor is. DC motors require brushes and a commutator or some type of electronic control. This makes these motors more fragile. The speed is variable depending on load which may or may not be useful.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Siemens 1PQ High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords