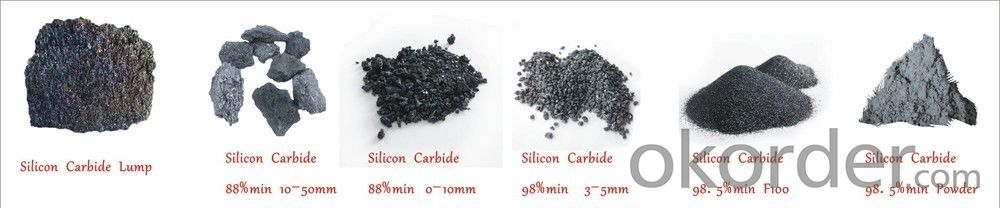

SIC Silicon Carbide Made in China for Abrasive and Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Brand Name: | CNBM | Model Number: | silicon carbide |

| Material: | SIC | Usage: | Polishing lapping refractory metallurgical | Abrasive Grain Sizes: | 12-3000# |

| Color: | Black and green | Name: | SIC | Application: | Polishing lapping refractory metallurgical |

| PAYMENT TERM: | T/T | Sample: | Provide | Package: | Jumbo Bag |

| Hardness: | 9.15 Mosh | Feature: | High Density | Quality: | Excellent |

Packaging & Delivery

| Packaging Details: | Silicon Carbide Powder:25kg bags loaded in 1 ton jumbo bags Silicon Carbide Lump: 1 ton loose in Jumbo bags. Or as customer request. |

| Delivery Detail: | 20 days after buyer's instruction |

Black Silicon Carbide is made by a precision water classification process and air flow classification using material that is produced from the reaction between high purity silica sand and petroleum coke in a resistance-type furnace. Measuring 9.0+ on the MOHS scale of hardness, silicon carbide is one of the hardest abrasives known in the industry. The inherent friability of the sharp crystalline structure assures the continuous exposure of new cutting edges, which produces a faster and cleaner cutting performance.

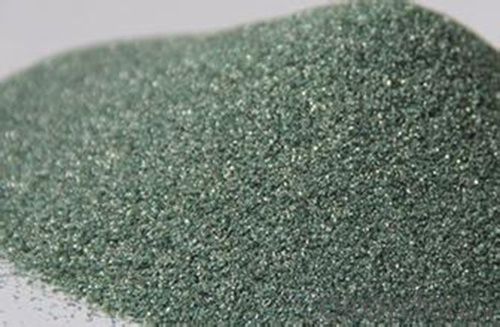

Green silicon carbide is produced as the same type as the black silicon carbide,except the different raw materials. It’s crystallization have higher purity and hardness.Green silicon carbide is suitable for processing hard alloy,metallic

and non-metallic material with hard and brittle feature such as copper, brass, aluminum,magnesium,jewel, optical glass, ceramics, etc. Super micro-power of it is also a kind of ceramics material.

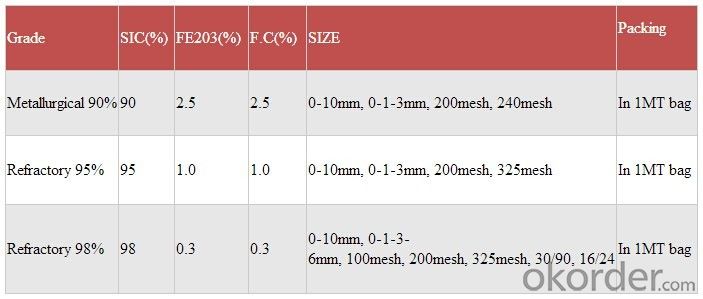

Chemical composition (%)

Grit size | SiC | F.C | Fe2O3 |

20# - 90# | ≥99.5 | <0.20< span=""> | ≤0.20 |

100# -180# | ≥98.5 | <0.25< span=""> | ≤0.50 |

220# - 240# | ≥97.5 | <0.25< span=""> | ≤0.70 |

F230 F360 | ≥97.5 | <0.30< span=""> | ≤0.70 |

F400 F600 | ≥95.5 | <0.30< span=""> | ≤0.70 |

F800 F1200 | ≥94.0 | <0.50< span=""> | ≤0.70 |

COMPANY PROFILE

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

Since 2004, the trading volume of CNBM International has been doubled in 5 successive years owing to the support of superior corporations and effort of all staff. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target.

In line with the business, CNBM International launched E-business platform Okorder.com.

Our goal is to transform CNBM International into the global leading brand in building materials industry within 3 to 5 years through innovation and reform, by strengthening the overall management of supply chain, developing and cultivating both domestic and overseas market, improving the procedure and information system, enhancing the ability to organize resources and to provide value-added services under a professional team and a learning organization.

With the advantages in Cement, Composite Materials, New Building Materials and Engineering, we mainly concentrate on coal, steel and construction equipments and give priority to solar and wind energy development simultaneously utilizing our competitive position on traditional building materials to achieve sales revenue of RMB10 Billion in 2013.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q:What is refractory brick?

- Capability1. Refractory brick is also known as firebrick. It is faint?yellow or brownish. Refractory brick with 770 ℃ at high temperatures is called for short firebrick. It is mainly used for building and smelting furnace. It is a refractory material made by fring refractory clay or other refractory material.

- Q:How long is the duration of fire resistance of hollow glass magnesium board

- Glass magnesium board is non-combustible board with excellent fire resistance ability, the continuous burning time of flame is 0, non-combustible at 800℃, no flame at 1200℃, achieving the highest level of fire retardant level A1; Partition System cooperated with high-quality keel can endure fire for more than 3 hours. In the process of combustion, a large amount of heat energy can be absorbed, and the temperature of the surrounding environment will be delayed.

- Q:Where is the distributing center of refractory materials in China?

- Refractories industry is one of the pillar industry of Gongyi City, the city's existing more than 300 refractory enterprises, the annual output value of 10 billion yuan, accounting for three of the city's GDPA share of the domestic market share of about 30% of refractories. Production of stereotypes, not stereotypes of two kinds of aluminum, magnesium, silicon and carbon four series of more than 1000 varieties of products, covering the whole country, and exported to Europe and other regions, is one of the Chinese refractory base. Yongan Road Subdistrict Office area is the center of the hinterland of refractories industry, Yongan is the theme of economic development, Chinese, Gongyi refractory chemical professional market, location, close to the aisle 310, Henan Provincial Highway S31, Yongan road and the construction of the Gong Teng speed transportation is very convenient.There is a good space for development and a relaxed business environment. Very conducive to customer management and development, is conducive to the full enjoyment of preferential policies in Gongyi, backed by trees good shade, head blue sky good development.

- Q:How should fireproof building materials be ranked?

- According to our national standard GB8624-97, the combustion performance of building materials are divided into the following levels: A class: Incombustible building materials: the material is almost incombustible. B1 class: Flame-retardant building materials: they are better in fire retardation. It is non-combustible when meeting open fire in the air or under high temperature, and it is difficult for the fire to spread quickly. Besides, when the fire source is removed, combustion stops immediately. B2 class: Combustible building material: It has certain fire retardation. In case of open fire in the air or at high temperature, it will immediately burst into flames, and easily lead to the spread of fire, such as the spread to wooden pillars, timber roof truss, timber beams, wood stairs, etc. B3 class: Flammable building material: It has no fire retardant effect at all, but is highly flammable with high fire risk. Hope my answer can be accepted.

- Q:What's the definition of fire endurance of the fire-resistant coating for steel structure?

- 1. Fire endurance. Conduct fire resistance test of any building component according to the standard time-temperature curve, and the time when it is subjected to the fire to the time when it loses support capability or fire insulation function or its integrality is destroyed is referred to fire endurance. 2. Steel has relatively low fire endurance which is usually 0.25h only, namely 15 minutes; 3. Of steel structure buildings, steel can be used as beams, pillars, etc. but its fire endurance is not enough (usually these components have higher requirement on fire endurance, and take pillar as an example, it is usually demanded that the fire endurance should be 2-3h), and under this condition, it needs to brush fire retardant coating so as to raise the fire endurance. As to the specific quantity or types of the fire retardant coating, it is decided upon the actual conditions. In short, the building material needs to meet the required fire endurance of the buildings.

- Q:what is the Specifications Grading for Fireproof rubber insulation materials ?

- At present, China Building Materials has two grading criteria for combustion performance. "Combustion Performance Classification Method of Building Materials" and "Combustion Performance Classification Method of Building Materials and Products" (GB8624-2006). Among them, one of the major changes of GB8624-2006 and GB8624-1997 is to divide the material combustion performance grading from homogenous material)Class A (composite sandwich material), B1, B2 and B3 level five minutes as A1, A2, B, C, D, E, F seven levels.

- Q:What antioxidant will be used in refractories?

- Specifically speaking, it is an antioxidant used in carbon refractory products, which belongs to the fire resistant technology. A kind of refractory used antioxidants, formula proportion is as follows calculated by weight percentage: aluminium zinc alloy 1 ~ 100, conventional antioxidants in 0 ~ 100. Described in the aluminum zinc alloy element of aluminum content is 3% ~ 3%, the rest is zinc. Described aluminium zinc alloy is powder or fibrous long; The biggest size and long fiber powder makeup of maximum diameter is 0.2 mm. Preparation of the present invention contains aluminum zinc alloy antioxidants can prevent carbon oxidation temperature range is big, less side effects, and can adjust the thermal expansion of refractory. Hope I can help you.

- Q:what's the fireproof levels of fireproof and thermal inuslation matertial?

- thermal insulation refractory material is also known as thermal insulation material, it has low thermal conductivity, average is below 0.3 w/m ℃). porosity is in commonly above 50%, bulk density is less than 1300 kg/m3 with low mechanical strength. thermal insulation refractory material, according to the operating temperature, can be divided into three kinds of materials: high temperature thermal insulation material (< 1200 ℃), medium temperature thermal insulation material (900 ~ 1200 ℃) and low temperature thermal insulation material (< 900 ℃). According to the bulk density, it can be divided into: general thermal?insulation?material (bulk density

- Q:what is the specs of thermal insulation refractory slab ?

- According to different requirements of each project to select the fire board. fireproof?panel should have product qualification certificate. Specifications shall comply with the requirements of design drawings and inspection reports from the National Fireproofing Protection Building Materials Inspection Center. General specifications are as follows: Length: it is determined according to the project width: 1200mm, 900mm; thickness: 9.5mm, 12mm, 15mm, 18mm, 25mm. Commonly used is 12mm. According to different requirements of each project to select the fire board. Fireproof?panel should have product qualification certificate. Specifications shall comply with the requirements of design drawings and inspection reports from the National Fireproofing Protection Building Materials Inspection Center. General specifications are as follows: Length: It is determined according to the project width: 1200mm, 900mm; thickness: 9.5mm, 12mm, 15mm, 18mm, 25mm. Commonly used is 12mm.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SIC Silicon Carbide Made in China for Abrasive and Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords