Short/long Fiber Needle Punched Non Woven Geotextile (PP PET)for Waterproof

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Short/long Fiber Needle Punched Non Woven Geotextile (PP PET):

Good tenacity, high density, loose structure, anti-corrosion, anti-aging, acid-and-alkali-resistance, good water absorption and permeability, high tensile strength, strong anti-deformation, filtering and isolation performance, operability for construction.

Main Features of Short/long Fiber Needle Punched Non Woven Geotextile (PP PET):

1. Filtration:

Used as the reversed filter to both prevent sand particulate from passing through and to allow free-flow for water and air.

2.Isolation:

Serving as isolation between ballast and subgrade or subgrade and soft ground in railway, surface course and subgrade or between different dam material in the airport and parking area, to isolate sand, stone in various diameter size from subgrade or other buildings.

3.Reinforcing: Used in engineering of road, railway, earth-rock dam, breakwater, airport, revetment refilling soil, slope and etc, to distribute soil body stress, prevent lateral soil movement and increase stability of soil.

4.Protection:

Used to prevent from scour by wind, wave, tide and/or rain and to protect bank and bottom, to avoid loss of soil and water

Surface Effects of Short Fiber Needle Punched Non-woven Geotextile:

Needle-punched, hot rolled (on single or both sides), jenappe, gum dipping (single or both sides)

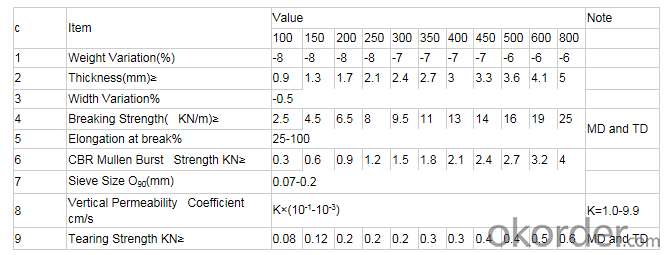

Specifications of Short/long Fiber Needle Punched Non Woven Geotextile (PP PET):

Short fiber nonwoven geotextile technical data

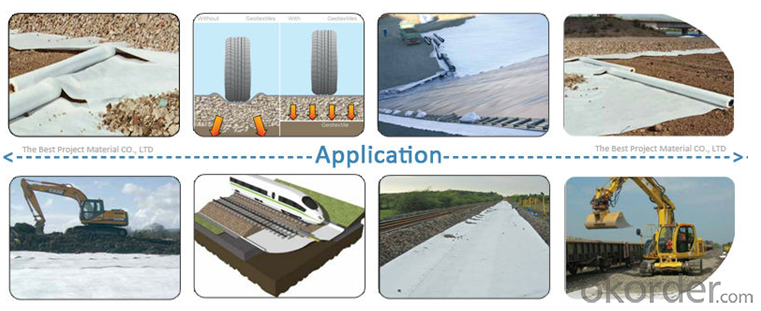

Applications of Short/long Fiber Needle Punched Non Woven Geotextile (PP PET):

Used in many civil engineering and building applications. Designed to offer filtration, separation, and ersion control functions.

Application industry

Some commen uses of the material includes the following:

1.Road stabilization applications

2.Roofs

3.Civil applications

4.Railway work

5.Landfill lining

6.Trenches

7.Dams

8.Fitration under rip rap and rocks

9.Environmental applications

IMages of Short/long Fiber Needle Punched Non Woven Geotextile (PP PET):

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:Geotextile 300g * 600mm * 300g is how is it?

- No you say 300g * 600mm * 300g this specification of the product, according to reason should be 300g * 0.6mm * 300g product 300g * 0.6mm * 300g product is a composite geomembrane specifications, also known as two cloth a film , Composite geotextile. That is, both sides of the upper and lower sides of a layer of 300g geotextile, the middle folder 0.6mm thickness of the plastic film. Composite geomembrane is to play the role of anti-seepage, generally used for water conservancy project seepage, civil engineering seepage and so on. The geotextile is from the water, reinforcement, protection, and can not achieve the role of anti-seepage. 300g * 0.6mm * 300g composite geomembrane price is generally between 11.5-13 yuan. You can do the next reference.

- Q:What are the factors to consider when selecting geotextiles for embankment stabilization?

- When selecting geotextiles for embankment stabilization, there are several important factors to consider. These include the strength and durability of the geotextile, its filtration and drainage properties, its compatibility with the soil and other materials, and its ability to withstand environmental conditions such as UV exposure and chemical exposure. Additionally, factors such as cost, installation requirements, and project-specific needs should also be taken into account.

- Q:Can geotextiles be used in road shoulder stabilization?

- Yes, geotextiles can be used in road shoulder stabilization. Geotextiles are often used to reinforce and stabilize road shoulders by providing separation, filtration, and reinforcement functions. They help prevent erosion and improve the strength and stability of the road shoulder, making it suitable for various types of traffic loads.

- Q:How do geotextiles improve the stability of slopes?

- Geotextiles improve slope stability by providing reinforcement and erosion control. They are placed within the slope to act as a barrier against soil movement, preventing erosion and enhancing the overall stability of the slope. Additionally, geotextiles help to distribute loads more evenly, reducing the potential for slope failure.

- Q:Polyester short wire geotextile 300 grams of water ministry indicators

- Polyester short wire geotextile 300 grams of water ministry indicators and GB indicators are the same. Can be implemented in accordance with GB / T-2008 standards. 300g polyester short wire geotextile per unit area quality deviation required ± 7%. 300g polyester short wire geotextile thickness ≥ 2.4mm. 300g polyester short wire geotextile width deviation of ± 0.5%. 300g polyester short wire geotextile breaking strength ≥ 9.5KN / m. 300g polyester short wire geotextile elongation at 25% to 100%. 300g polyester short wire geotextile CBR burst strength ≥ 1.5KN. 300g polyester short wire geotextile equivalent pore size 0.07mm ~ 0.2mm. 300g polyester short wire geotextile vertical permeability coefficient (1.0 ~ 9.9) * (10 negative square ~ 10 negative three times). 300g polyester short wire geotextile tear strength ≥ 0.24KN.

- Q:How do geotextiles improve the performance of shorelines?

- Geotextiles improve the performance of shorelines by providing erosion control, stabilizing the soil, and enhancing filtration. They act as a barrier against wave energy and currents, preventing the loss of sediment and minimizing erosion. Additionally, geotextiles help to reinforce and stabilize the shoreline, reducing the risk of land subsidence or collapse. Their permeable nature allows water to pass through while trapping sediment, reducing the accumulation of silt and pollutants. Overall, geotextiles play a crucial role in protecting and maintaining the integrity of shorelines.

- Q:What are the factors to consider when selecting a geotextile?

- When selecting a geotextile, there are several factors to consider. Firstly, the application or purpose of the geotextile is important. Different geotextiles are designed for specific functions such as filtration, separation, drainage, or reinforcement. Understanding the specific requirements of the project and matching them with the appropriate geotextile is crucial. Secondly, the site conditions need to be evaluated. Factors such as soil type, slope stability, groundwater levels, and expected loads or stresses should be considered. The geotextile should be able to withstand these conditions and provide the necessary performance. Thirdly, the durability and longevity of the geotextile should be assessed. Factors like UV resistance, resistance to chemicals or biological degradation, and the expected lifespan should be evaluated to ensure that the selected geotextile can withstand the anticipated environmental conditions. Additionally, the installation and maintenance requirements should be taken into account. Some geotextiles may require specialized equipment or techniques for installation, while others may need periodic monitoring or maintenance. Understanding these requirements is essential for a successful project. Lastly, cost-effectiveness is an important factor. While it is crucial to select a geotextile that meets the project requirements, it is also necessary to consider the associated costs. Evaluating the initial cost, as well as the long-term benefits and potential savings, helps in making an informed decision. In summary, the factors to consider when selecting a geotextile include the specific application, site conditions, durability, installation requirements, and cost-effectiveness.

- Q:How do geotextiles help in subsurface drainage?

- Geotextiles help in subsurface drainage by providing a filtration barrier that allows water to pass through while preventing the migration of fine soil particles. This helps maintain the integrity and effectiveness of the drainage system by preventing clogging and promoting efficient water flow.

- Q:How do geotextiles help with soil confinement in erosion control block walls?

- Geotextiles play a crucial role in soil confinement within erosion control block walls by acting as a filter and separator. They prevent soil particles from washing out while allowing water to drain through, thereby reducing hydrostatic pressure and the risk of wall failure. Additionally, geotextiles enhance the overall stability and longevity of the wall by providing reinforcement and preventing soil erosion.

- Q:Are geotextiles environmentally friendly?

- Yes, geotextiles can be considered environmentally friendly. Geotextiles are designed to have minimal impact on the environment and can be made from recycled materials. They can help with erosion control, soil stabilization, and filtration, reducing the need for harmful chemicals or excessive soil excavation. Additionally, geotextiles are often biodegradable or can be recycled at the end of their lifespan, further contributing to their environmental friendliness.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Short/long Fiber Needle Punched Non Woven Geotextile (PP PET)for Waterproof

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords