Shaft platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

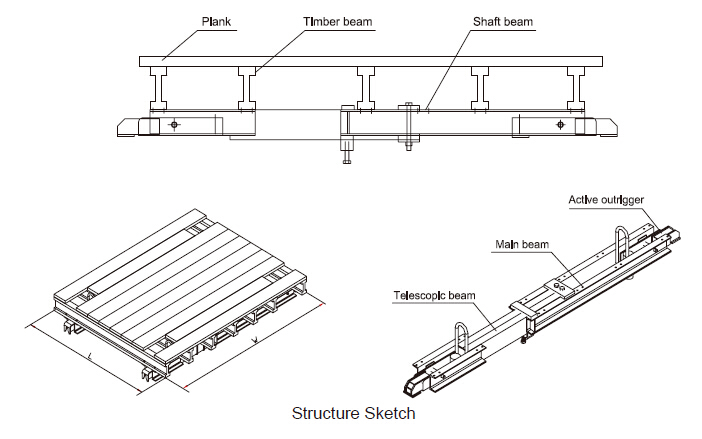

Shaft Platform

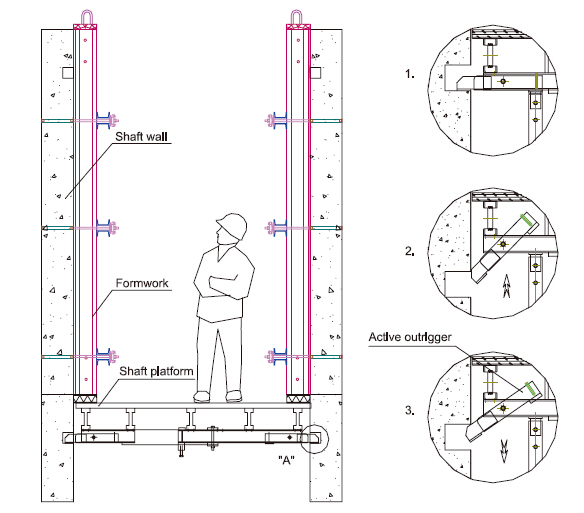

As operating platform, the shaft platform is mainly used in the concrete pouring of elevator shaft,

equipment shaft, stair shaft of high-rise building and so on.

Characteristics:

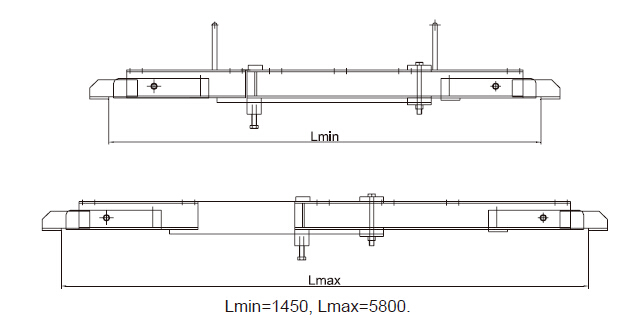

◆ The length of shaft beam is adjustable.

◆ Flexible structure makes lifting easier.

- Q:Can steel formwork be used for both reinforced and non-reinforced concrete structures?

- Yes, steel formwork can be used for both reinforced and non-reinforced concrete structures. Steel formwork is a versatile and durable option that can withstand the pressure exerted by the concrete during the casting process. It can be easily assembled and disassembled, making it suitable for various types of construction projects. Whether it is a reinforced structure that requires additional support for the reinforcement bars or a non-reinforced structure that only requires a temporary mold, steel formwork can be used effectively in both cases. Its strength and stability allow for the creation of precise shapes and dimensions, ensuring the desired outcome for any concrete structure.

- Q:Can steel formwork be used for both slab and column construction?

- Both slab and column construction can utilize steel formwork. This type of formwork has numerous advantages compared to wood or plastic alternatives. Its durability allows it to endure the pressure exerted by fresh concrete, making it ideal for both slab and column construction. When used for slab construction, steel formwork provides a robust and rigid support system that ensures the concrete is poured and cured in the desired shape and dimensions. The steel panels are simple to assemble and disassemble, enabling efficient and repeated use on multiple projects. This ultimately saves both time and money in the long term. Likewise, steel formwork is suitable for column construction. The adjustable panels can be easily customized to accommodate various column sizes and shapes, offering design flexibility. Additionally, steel formwork provides a smooth surface finish, resulting in high-quality columns. Furthermore, steel formwork is resistant to warping, swelling, and shrinking, which are common issues with other types of formwork materials. This guarantees the accuracy and structural integrity of the concrete structure over time. In conclusion, steel formwork is a versatile and dependable choice for both slab and column construction. Its strength, durability, and user-friendliness have made it a favored option among construction professionals.

- Q:How does steel formwork affect the overall construction cost estimate?

- The overall construction cost estimate can be affected both positively and negatively by the use of steel formwork. On the positive side, steel formwork is known for its durability and reusability, which can result in long-term cost savings. Unlike traditional timber formwork, steel formwork can endure multiple uses, reducing the constant need for replacement and decreasing material expenses over time. Moreover, steel formwork offers better dimensional accuracy and stability, leading to quicker construction processes. This can result in shorter project durations and decreased labor costs, ultimately having a positive impact on the overall construction cost estimate. Nevertheless, it is important to consider that steel formwork generally incurs higher initial costs compared to timber formwork. The upfront investment required for steel formwork can be substantial, particularly for large-scale projects. This cost encompasses the acquisition or rental of the steel formwork system, transportation, and installation expenses. Additionally, the assembly and dismantling of steel formwork may necessitate skilled labor, which can contribute to higher labor costs. It is crucial to have experienced workers who are familiar with steel formwork systems, as any errors during the construction process can lead to added expenses and delays. Ultimately, the effect of steel formwork on the construction cost estimate relies on various factors such as the project's scale, duration, and the availability of skilled labor. Though steel formwork may involve higher upfront costs, the long-term advantages of durability, reusability, and enhanced construction efficiency can outweigh these initial expenses and positively impact the overall construction cost estimate.

- Q:How does steel formwork affect the overall strength of the structure?

- Steel formwork can significantly enhance the overall strength of a structure. Its robust and durable nature ensures that the concrete is cast and supported effectively, resulting in a more stable and solid construction. Steel formwork provides excellent reinforcement and support to the concrete during the curing process, preventing any deformation or cracking. Additionally, its high load-bearing capacity allows for the construction of taller and more complex structures, thereby increasing the overall strength and integrity of the building.

- Q:Is steel formwork more durable than other types of formwork?

- Yes, steel formwork is generally considered more durable than other types of formwork. Steel has high strength and can withstand heavy loads, making it ideal for construction projects that require repetitive use and long-term durability. Additionally, steel formwork is resistant to warping, shrinking, and moisture damage, which further enhances its durability compared to other formwork materials such as wood or aluminum.

- Q:Can steel formwork be easily transported to different job sites?

- Yes, steel formwork can be easily transported to different job sites. Steel formwork is durable, lightweight, and can be disassembled and reassembled easily. It can be stacked and transported using trucks or trailers, making it a convenient option for construction projects in different locations.

- Q:How does steel formwork affect the construction schedule?

- Steel formwork can greatly affect the construction schedule in a positive way. Due to its strength and durability, steel formwork allows for faster and more efficient construction processes. This results in reduced construction time and faster completion of the project. Additionally, steel formwork is reusable, which further saves time and resources as it can be quickly dismantled and used for future construction projects.

- Q:Can steel formwork be used for both horizontal and vertical construction elements?

- Yes, steel formwork can be used for both horizontal and vertical construction elements. Steel formwork is versatile and can be easily adapted to different shapes and sizes, making it suitable for various construction applications.

- Q:Can steel formwork be used for both small and large-scale construction projects?

- Yes, steel formwork can be used for both small and large-scale construction projects. Steel formwork is highly versatile and can be easily customized to meet the specific requirements of different project sizes. It offers strength, durability, and stability, making it suitable for various construction applications, ranging from small residential buildings to large commercial structures.

- Q:How does steel formwork contribute to improved construction site access?

- Improved construction site access is facilitated by steel formwork in various ways. Firstly, the durability and reliability of steel formwork enable the construction of robust and stable structures. As a result, workers can navigate the formwork with confidence, assured of its stability and integrity. Secondly, the highly versatile nature of steel formwork allows for customization according to the specific requirements of any project. This flexibility enables the creation of intricate shapes and designs, improving access to different areas of the construction site. For instance, curved or inclined formwork can be utilized to construct ramps, staircases, or other access points that facilitate movement and navigation. Moreover, steel formwork is renowned for its exceptional load-bearing capacity, enabling it to support heavy loads and equipment. This is especially crucial in construction projects involving cranes, scaffolding, or other substantial machinery. By providing a sturdy platform, steel formwork ensures that access is maintained even during the transportation of heavy loads across the site. Furthermore, the quick and effortless assembly of steel formwork significantly reduces construction time and enhances on-site access. Its modular design allows for efficient installation and dismantling, enabling access points to be created or modified promptly. This proves particularly advantageous in time-sensitive projects or situations where the site layout requires frequent adaptation. To conclude, steel formwork contributes to improved construction site access through its durability, versatility, load-bearing capacity, and ease of assembly. These attributes not only enhance worker safety but also facilitate movement around the site, ultimately optimizing productivity and efficiency in the construction process.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Shaft platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords