Shaft-Platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

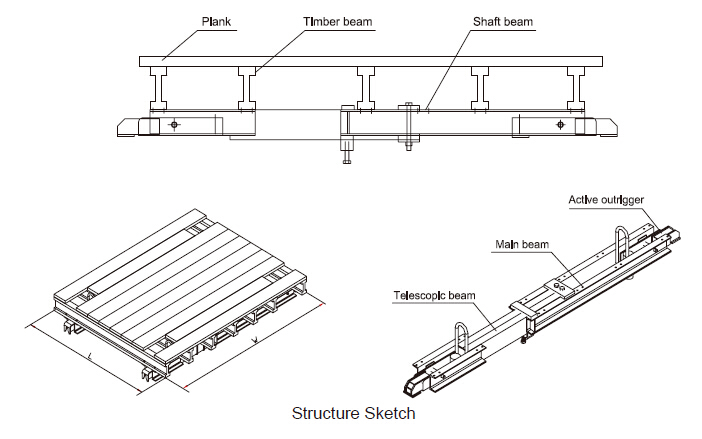

Shaft Platform

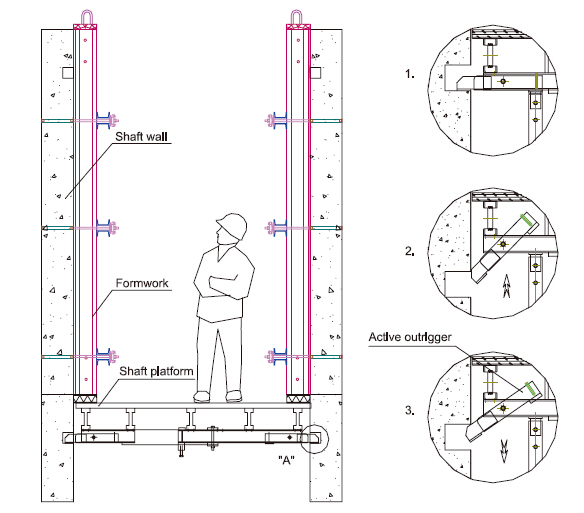

As operating platform, the shaft platform is mainly used in the concrete pouring of elevator shaft,

equipment shaft, stair shaft of high-rise building and so on.

Characteristics:

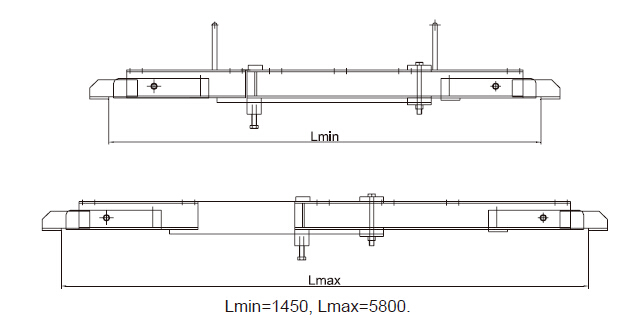

◆ The length of shaft beam is adjustable.

◆ Flexible structure makes lifting easier.

- Q:Can steel formwork be used for both cast-in-place and precast concrete structures?

- Steel formwork is capable of being utilized for both cast-in-place and precast concrete structures. It is a flexible and long-lasting option for establishing formwork systems for concrete construction. Its assembly and disassembly are effortless, rendering it appropriate for structures that are either temporary or permanent. Regarding cast-in-place concrete structures, steel formwork is frequently employed to confine the wet concrete throughout the pouring and curing process. It offers a rigid and consistent mold, which aids in shaping the concrete according to the desired form and dimensions. Steel formwork is particularly suitable for projects that necessitate intricate shapes, such as curved walls or distinctive architectural features. In the case of precast concrete structures, steel formwork is often deployed to fabricate the molds into which the concrete is poured. These molds can be tailored to meet precise project requirements, thus enabling accurate and consistent production of precast components. Steel formwork supplies the essential support and stability for the precast elements as they solidify and harden. To sum up, steel formwork is a suitable alternative for both cast-in-place and precast concrete structures. Its robustness, adaptability, and user-friendly nature render it a favored choice in the construction industry.

- Q:How does steel formwork affect the overall waste management of the construction process?

- Steel formwork can have a significant impact on the overall waste management of the construction process. Unlike traditional timber formwork, steel formwork is highly durable and reusable, which helps to minimize waste generation. This is because steel formwork can be used multiple times, reducing the need for frequent replacements and thereby reducing the amount of waste generated from discarded formwork materials. Moreover, steel formwork is typically fabricated off-site and can be easily disassembled and transported to different construction sites. This not only saves time and labor but also reduces the amount of waste generated during the construction process. In addition to its reusability, steel formwork is also recyclable. At the end of its life cycle, steel formwork can be melted down and reused to produce new steel products. This allows for a closed-loop recycling system, reducing the need for raw material extraction and minimizing the environmental impact associated with steel production. Another aspect to consider is the reduced maintenance required for steel formwork compared to other types of formwork. Since steel is highly resistant to wear and tear, it requires minimal repairs or replacements. This further reduces the waste generated during the construction process. Furthermore, steel formwork offers better dimensional accuracy and stability compared to other formwork materials. This results in reduced material wastage as the formwork provides precise shape and alignment, minimizing the need for excessive concrete pouring or trimming. Overall, the use of steel formwork positively impacts waste management in the construction process by minimizing waste generation, promoting reusability, facilitating recycling, reducing maintenance needs, and enhancing construction accuracy.

- Q:What are the typical environmental considerations when using steel formwork?

- When using steel formwork, there are several typical environmental considerations that need to be taken into account. Firstly, the production of steel requires a significant amount of energy and natural resources. This means that the extraction of raw materials and the manufacturing process can contribute to environmental degradation, including the emission of greenhouse gases. To mitigate these impacts, it is important to consider the use of recycled or reclaimed steel whenever possible. This helps reduce the demand for new steel production and minimizes the environmental footprint associated with the formwork. Another important consideration is the waste generated during the construction process. Steel formwork can produce a significant amount of waste, such as offcuts and discarded pieces. Proper waste management practices, such as recycling or reusing these materials, should be implemented to minimize the environmental impact. Additionally, the transportation of steel formwork can contribute to carbon emissions and air pollution. It is important to optimize transportation routes and modes to reduce the distance traveled and choose more sustainable transportation options, such as rail or water, whenever feasible. Furthermore, the use of steel formwork can have an impact on the site where construction takes place. The installation and removal of the formwork can disturb the natural environment, leading to soil erosion and habitat destruction. Implementing erosion control measures and minimizing the footprint of the formwork can help mitigate these impacts. Lastly, the longevity and durability of steel formwork should be considered. If properly maintained and reused, steel formwork can have a long lifespan, reducing the need for frequent replacement and ultimately reducing waste and resource consumption. Overall, when using steel formwork, it is important to consider the entire lifecycle of the material and implement sustainable practices to minimize its environmental impact. This includes using recycled steel, managing waste properly, optimizing transportation, mitigating site disturbance, and promoting durability and reuse.

- Q:Are there any specific considerations for using steel formwork in earthquake-prone areas?

- Yes, there are specific considerations for using steel formwork in earthquake-prone areas. Steel formwork is known for its strength and durability, which is why it is often preferred in seismic regions. However, there are several factors that need to be taken into account when using steel formwork in earthquake-prone areas: 1. Flexibility: Steel formwork should be designed to have the necessary flexibility to withstand seismic forces. It should be able to absorb and dissipate the energy generated during an earthquake, reducing the risk of structural damage. 2. Connection details: The connection details between the steel formwork components should be carefully designed and engineered to ensure proper load transfer and resistance to seismic forces. Special attention should be given to the joints and connections to prevent failure or collapse during an earthquake. 3. Reinforcement: Additional reinforcement might be required to enhance the strength and stiffness of the steel formwork system. This reinforcement can be in the form of additional steel bars, cross bracing, or diagonal struts to provide increased resistance against lateral forces. 4. Anchorage: Proper anchorage of the steel formwork to the supporting structure is crucial in earthquake-prone areas. The formwork should be securely anchored to the foundation or the structural elements to prevent displacement or movement during an earthquake. 5. Inspection and maintenance: Regular inspection and maintenance of the steel formwork system are essential in earthquake-prone areas. Any damage or wear should be identified and repaired promptly to ensure the integrity and stability of the formwork system. 6. Compliance with building codes: It is important to ensure that the steel formwork system complies with the local building codes and regulations for seismic design. These codes provide guidelines and requirements for the design, installation, and use of formwork in earthquake-prone areas. By considering these specific factors, using steel formwork in earthquake-prone areas can provide enhanced structural resilience and contribute to the overall safety and durability of the construction project.

- Q:Can steel formwork be used for curved or irregular structures?

- Indeed, curved or irregular structures can be constructed using steel formwork. The utilization of steel formwork provides design flexibility and enables the easy shaping or fabrication of intricate geometries. Its strength and durability allow it to endure the immense pressure exerted during the pouring of concrete. With the ability to effortlessly adjust and adapt, steel formwork is well-suited for constructing structures with distinctive architectural designs or intricate layouts that incorporate curves, bends, or irregular shapes. Furthermore, the implementation of steel formwork guarantees a sleek finish to the concrete surface, resulting in structures of exceptional quality and aesthetic appeal.

- Q:Can steel formwork be used for architectural concrete finishes?

- Yes, steel formwork can be used for architectural concrete finishes. Steel formwork offers a number of advantages that make it suitable for creating high-quality architectural finishes. Firstly, steel formwork provides excellent dimensional accuracy and stability, ensuring that the concrete is poured and cured in the desired shape and size. This allows for precise and intricate architectural detailing. Furthermore, steel formwork is highly durable and can withstand the pressure and weight of the concrete during the pouring and curing process. This durability ensures that the formwork remains intact and does not deform or warp, resulting in a smooth and even concrete finish. Steel formwork also allows for easy demolding, as it can be easily dismantled without damaging the concrete structure. This makes it convenient for achieving architectural finishes that require complex shapes or multiple components. In addition, steel formwork can be easily reused, making it a cost-effective option for architectural projects. It can withstand multiple uses, reducing the need for frequent replacements and saving both time and money. However, it is important to note that the choice of formwork material depends on the specific requirements of the architectural concrete finish. While steel formwork is suitable for most applications, there may be instances where other materials such as wood or plastic formwork are more appropriate. Consulting with a structural engineer or a construction professional can help determine the most suitable formwork material for a particular architectural concrete finish.

- Q:How does steel formwork contribute to the overall structural integrity of a building?

- Steel formwork contributes to the overall structural integrity of a building by providing a strong and rigid framework for pouring concrete. It ensures accurate alignment and dimensional stability, resulting in consistent and reliable construction. The use of steel formwork also enhances the load-bearing capacity of the structure, allowing it to withstand heavy loads and external forces. Additionally, steel formwork offers excellent durability and longevity, reducing the risk of structural failures over time.

- Q:How does steel formwork contribute to the overall aesthetics of a structure?

- Steel formwork can contribute to the overall aesthetics of a structure by providing a smooth and clean finish to concrete surfaces. Its rigid and durable nature allows for precise shaping and detailing, resulting in sharp edges and smooth surfaces that enhance the visual appeal of a building. Additionally, steel formwork offers flexibility in design, enabling architects to create complex and unique shapes, adding an artistic touch to the structure.

- Q:What are the considerations when selecting the size and spacing of steel formwork panels?

- When selecting the size and spacing of steel formwork panels, several considerations need to be taken into account. First, the size of the panels should be determined based on the dimensions of the concrete structure being formed. The panels should be able to accommodate the desired shape and size of the concrete element. Secondly, the spacing between the panels should be chosen to ensure adequate support and stability. The spacing should be determined based on the load-bearing capacity of the panels and the weight of the concrete being poured. It is important to have proper spacing to prevent deflection or deformation of the formwork. Additionally, the size and spacing of the panels should also consider the ease of handling and installation. Panels that are too large or heavy may be difficult to transport and assemble, leading to time and labor inefficiencies. On the other hand, panels that are too small may result in excessive joints, increasing the chances of leakage or misalignment. Overall, the selection of the size and spacing of steel formwork panels should prioritize structural integrity, functionality, and ease of use to ensure successful and efficient concrete formwork construction.

- Q:How does steel formwork improve the quality of concrete structures?

- Steel formwork is widely employed in the construction industry due to its numerous advantages, which greatly enhance the quality of concrete structures. Here are several ways in which steel formwork improves the quality of concrete structures: 1. Superior Form Stability: Compared to traditional wooden formwork, steel formwork offers enhanced form stability. It is more rigid and less prone to warping or distortion, guaranteeing that the concrete is poured into an accurate and consistent shape. This results in straighter walls, smoother surfaces, and overall better structural integrity. 2. Increased Durability: Steel formwork is highly durable and capable of withstanding the harsh conditions of construction sites. Unlike wooden formwork, it does not rot, decay, or easily sustain damage. Its long lifespan allows for multiple reuses, thereby reducing costs and waste. This durability translates into stronger and longer-lasting concrete structures. 3. Precise Dimensions: Steel formwork is manufactured with high precision, enabling accurate and consistent dimensions in concrete structures. It facilitates achieving the desired shape, size, and alignment of elements. This accuracy is crucial in ensuring that the structure meets required specifications and architectural designs, resulting in a high-quality finished product. 4. Improved Surface Finish: Steel formwork provides a smooth and even surface finish to concrete structures. The design of steel panels minimizes surface imperfections and prevents leakage of the concrete mixture. This results in visually appealing structures with uniform finishes, which reduces the need for additional plastering or finishing work. 5. Enhanced Safety: Steel formwork enhances safety during the construction process. Its sturdy and rigid nature provides a stable platform for workers to pour and work with concrete. The risk of accidents, such as formwork failure or collapse, is significantly reduced with steel formwork, ensuring the safety of workers and the integrity of the structure. In conclusion, the utilization of steel formwork in concrete construction brings multiple benefits that contribute to the improvement of structure quality. With its form stability, durability, precise dimensions, improved surface finish, and enhanced safety, steel formwork plays a vital role in ensuring the integrity, aesthetics, and longevity of concrete structures.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Shaft-Platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords