Shaft Platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

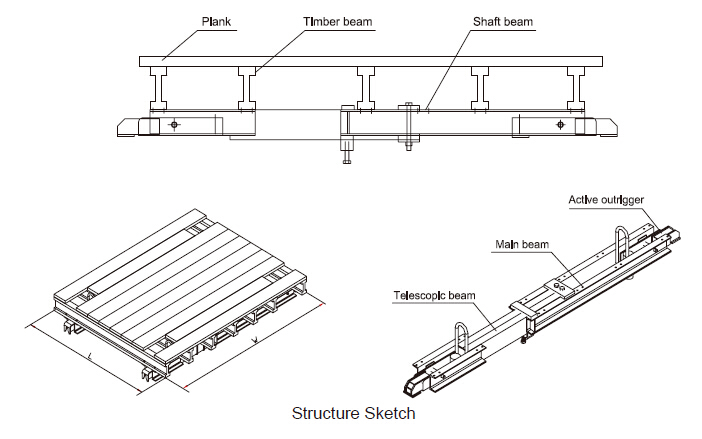

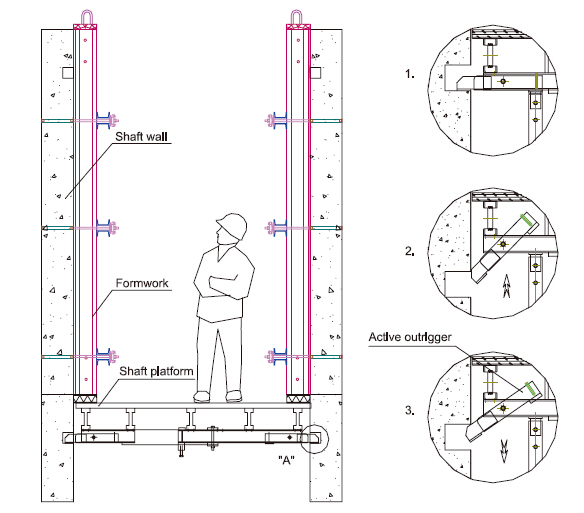

Shaft Platform

As operating platform, the shaft platform is mainly used in the concrete pouring of elevator shaft,

equipment shaft, stair shaft of high-rise building and so on.

Characteristics:

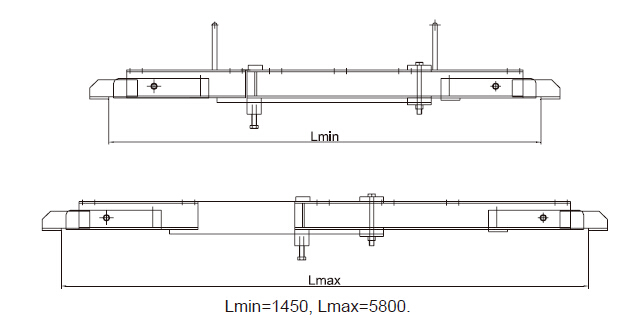

◆ The length of shaft beam is adjustable.

◆ Flexible structure makes lifting easier.

- Q:Can steel formwork be used for stadium construction projects?

- Yes, steel formwork can be used for stadium construction projects. Steel formwork refers to the use of steel panels and frames to create temporary molds or structures for pouring concrete. This method is widely used in construction projects, including stadium construction, due to its durability, strength, and reusability. Stadium construction projects often require large-scale concrete pouring for various elements such as foundations, beams, columns, and slabs. Steel formwork provides the necessary support and stability during the concrete pouring process, ensuring accurate and precise concrete placement. Moreover, steel formwork can withstand the high pressures of concrete pouring, making it suitable for large-scale projects like stadiums. Steel formwork also offers several advantages over traditional formwork materials such as timber or plywood. Firstly, steel formwork is highly durable and can be used for multiple construction cycles, making it cost-effective in the long run. Secondly, steel formwork provides better dimensional accuracy and consistency, resulting in better quality concrete structures. Additionally, steel formwork is fire-resistant, weather-resistant, and can be easily cleaned and maintained. Furthermore, steel formwork can be customized and fabricated according to the specific design requirements of the stadium. This flexibility allows for efficient and precise construction, ensuring that the stadium's structural elements are built to the desired specifications. In conclusion, steel formwork is a suitable and preferred choice for stadium construction projects. Its strength, durability, reusability, and customization options make it an ideal solution for creating temporary molds and structures during the concrete pouring process.

- Q:What are the considerations when selecting the thickness of steel formwork?

- When selecting the thickness of steel formwork, there are several considerations to keep in mind. Firstly, the load-bearing capacity required for the formwork needs to be determined, taking into account factors such as the weight of the concrete, the expected live loads, and any additional loads that may be applied during construction. The desired lifespan of the formwork is another crucial factor, as thicker steel sheets tend to have a longer service life. The complexity and shape of the structure being formed should also be considered, as more intricate designs may require thicker steel to ensure stability and prevent deformation. Additionally, the cost implications of using thicker steel must be taken into account, balancing the benefits of increased strength and durability with the associated expenses. Overall, the selection of steel formwork thickness should be based on a thorough evaluation of these factors to ensure a safe and efficient construction process.

- Q:How does steel formwork affect the overall acoustics of the building?

- The overall acoustics of a building can be greatly influenced by the use of steel formwork. Steel formwork, due to its dense and rigid nature, tends to reflect sound waves rather than absorb them. This reflection can result in increased noise levels and the creation of echoes within the building. The utilization of steel formwork can lead to a longer reverberation time, which is the duration it takes for sound to diminish by 60 decibels. This can result in poor speech clarity and reduced audio quality within the space. Moreover, the sound reflections from steel formwork can disrupt the natural acoustic properties of the room, potentially causing distortion and resonance problems. To tackle these challenges, it is possible to incorporate sound-absorbing materials on the interior surfaces of the building. This can help decrease the reflection and reverberation of sound waves, thereby enhancing the overall acoustics of the space. Possible options include the use of acoustic panels, insulation materials, and ceiling treatments that absorb and scatter sound. When determining the type of formwork to be used, it is crucial to consider the specific requirements of the building and its intended purpose. For spaces where excellent acoustics are essential, such as auditoriums, concert halls, or recording studios, alternative formwork materials that offer superior sound absorption properties might be preferred over steel formwork. However, in other applications where acoustics are less critical, steel formwork can still be utilized effectively by incorporating appropriate sound-absorbing measures. In conclusion, the selection of steel formwork can significantly impact the acoustics of a building. By carefully considering sound absorption and reflection properties, and by implementing additional acoustic treatments, it is possible to mitigate any negative effects and create a more pleasant and functional acoustic environment.

- Q:Can steel formwork be used for airport runway construction?

- Yes, steel formwork can be used for airport runway construction. Steel formwork is a versatile and durable option for creating concrete structures, including runways. It offers several advantages over other types of formwork, such as timber or aluminum. Firstly, steel formwork provides a high level of strength and stability, ensuring that the concrete pouring process is efficient and accurate. This is crucial for runway construction, as the surface needs to be even and strong enough to withstand heavy aircraft traffic. Secondly, steel formwork is reusable, making it cost-effective for large-scale projects like airport runways. Its durability allows it to be used multiple times, reducing the need for frequent replacements and saving both time and money. Additionally, steel formwork can be easily assembled and disassembled, making it convenient for construction sites with tight schedules or limited space. Its modular design allows for quick installation and adjustment, enabling efficient construction progress. Furthermore, steel formwork provides excellent resistance to various weather conditions, including extreme temperatures and moisture. This is vital for airport runways, as they are exposed to constant wear and tear from aircraft, as well as harsh weather conditions. In conclusion, steel formwork is a suitable choice for airport runway construction due to its strength, reusability, ease of use, and resistance to different weather conditions. Its ability to provide a stable and durable surface makes it an ideal option for creating runways capable of handling heavy aircraft traffic.

- Q:How does steel formwork handle different concrete surface cleaning methods?

- Steel formwork is a durable and versatile option for concrete construction projects. When it comes to cleaning the concrete surface, steel formwork can handle various methods effectively. One common method of cleaning concrete surfaces is pressure washing. Steel formwork can withstand high-pressure water jets without any damage. The smooth and non-porous surface of steel formwork makes it easy to remove dirt, debris, and any other unwanted materials from the concrete surface. Pressure washing can effectively clean the surface, ensuring a smooth and even finish. Another method used for concrete surface cleaning is chemical cleaning. Steel formwork is resistant to most chemicals commonly used for cleaning purposes. This allows for the use of various cleaning agents to remove stubborn stains, oil, grease, and other contaminants from the concrete surface. The chemical cleaning process can be performed without causing any harm or degradation to the steel formwork. In some cases, manual cleaning methods may also be employed. Steel formwork can handle manual scrubbing, brushing, or scraping without any issues. The strength and durability of steel make it suitable for manual cleaning methods, which may be necessary for removing tough stains or debris that cannot be easily removed through other means. Overall, steel formwork is an ideal choice for handling different concrete surface cleaning methods. Its resistance to pressure washing, chemical cleaning, and manual cleaning methods ensures that the concrete surface can be effectively cleaned without causing any damage to the formwork. This allows for a clean and aesthetically pleasing finish, while also maintaining the structural integrity of the formwork.

- Q:Can steel formwork be used for water storage tanks?

- Water storage tanks can indeed utilize steel formwork. Because of its strength, durability, and ability to withstand water pressure and weight, steel formwork is a popular choice. Its purpose is to create a sturdy structure that securely holds the concrete in place during the setting process, resulting in a robust and leakproof tank. Moreover, steel formwork is convenient to assemble and disassemble, making it a versatile option for tanks of different sizes and shapes. Nevertheless, it is crucial to ensure proper coating or treatment to prevent corrosion caused by water and external factors.

- Q:What are the different types of accessories used with steel formwork?

- Steel formwork is commonly enhanced with various accessories to improve its functionality and effectiveness in construction projects. Some examples of these accessories are: 1. Formwork Wedges: These small wedges, made of steel or plastic, secure the formwork panels together. They preserve accurate alignment and stability of the formwork system when concrete is poured. 2. Formwork Clamps: Designed to hold the formwork panels in place, clamps prevent any movement or displacement during concrete pouring and curing. They are typically steel and come in different sizes and designs to accommodate various formwork needs. 3. Formwork Ties: Ties connect the formwork panels and provide structural stability to the system. Available in steel or plastic and in different lengths and types (such as snap ties, wedge ties, and loop ties), they reinforce the formwork. 4. Formwork Braces: Steel braces reinforce and strengthen the formwork system. They support the panels, preventing bending or deformation during concrete pouring. 5. Formwork Hangers: These adjustable steel hangers suspend the formwork panels at the desired height, providing support. They can accommodate different formwork heights and configurations. 6. Formwork Spacers: Spacers maintain uniform spacing between formwork panels, ensuring consistent thickness in concrete walls or slabs. They are available in various sizes and shapes, made of plastic or steel. 7. Formwork Release Agents: These agents prevent concrete from adhering to the formwork surface. Before pouring concrete, they are applied to the panels, allowing for easy removal once the concrete has cured. Overall, these accessories are vital for maintaining the stability, alignment, and functionality of steel formwork systems. They contribute to the efficiency and quality of construction projects by providing reliable support and reinforcement during concrete pouring.

- Q:What are the typical load capacities of steel formwork systems?

- The load capacities of steel formwork systems can differ based on their specific type and design. Steel formwork systems are generally recognized for their ability to bear heavy loads. In the case of horizontal formwork systems, like slab formwork, the load capacities can range from 60 to 100 kN/m2 or even higher, depending on factors such as slab thickness and support spacing. This allows for the effective construction of reinforced concrete slabs and beams that can withstand substantial loads. Vertical formwork systems, such as wall formwork and column formwork, are constructed to withstand the weight of fresh concrete and the lateral pressure exerted during pouring. The load capacities of these systems can vary based on the height and width of the structure being formed. Usually, wall formwork systems can support loads ranging from 50 to 80 kN/m2, while column formwork systems can handle loads ranging from 60 to 100 kN/m2. It is important to note that these load capacities serve as general guidelines and may differ based on the design and manufacturer of the steel formwork system. It is always recommended to refer to the manufacturer's specifications and guidelines to ensure that the formwork system is used within its designated load capacities for safe and efficient construction.

- Q:Can steel formwork be used for both indoor and outdoor construction projects?

- Yes, steel formwork can be used for both indoor and outdoor construction projects. Steel is a durable and versatile material that can withstand different weather conditions, making it suitable for various construction environments.

- Q:How does steel formwork affect the overall weight of the structure?

- Steel formwork can significantly affect the overall weight of a structure as it is typically heavier than other types of formwork materials such as wood or aluminum. The weight of steel formwork can increase the dead load on the structure, potentially requiring additional structural support and impacting the design and construction process. However, steel formwork offers advantages in terms of durability, strength, and reusability, making it a preferred choice in certain construction projects despite its impact on the overall weight.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Shaft Platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords