SGB10-100-2500-10 H-class insulation three-phase dry-type transformer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production introduction

Our company has developed this product by ourselves.As a high performance,high safety,pollution free dry-type transformer,it is suitable for the harsh environments where there is a high fire protection requirement,the great load fluctuation and the site where is of filth and moisture.For example:airport,power plant,metallurgy operation,hospital,high building shopping center,densely inhabited ared,petrochemical industry,nuclear power station and nuclear submarine,elc.

Normal service conditions

1.A unique ceramic type of insulation structure is adopted in H-class high strength insulation cylinders and high-frequency ceramic cushion blocks are adopted to ensure that no deformation will occur.

2.The high-voltage and low-voltage windings are made of NOMEX wrapped flat copper wires and imported copper foils.And they are sealed with high strength insulation materials.

3.The iron core is made of laminated imported high-quality silicon-steel sheets of high magnetic conductivity with a 45 stepwise all-bias structure.A flexible fastening unit is adopted to fasten the winding and iron core,which ensures a relatively low no-load loss and low noise.

4.Outlet terminals are fixed to the top of winding,taps are in the middle of winding,low-voltage line terminal are in plate-type current-conducting rows for which cold pressure welding is adopted.

Normal service conditions

1)Altitude should not be over 1000m:indoor type

2)Highest ambient temperature should not over:+40oC;Highest daily average should not over temperature:+30oC

3)Highest annual average temperature should not over +20oC,lowest temperature should not below -5oC,We can provide transformer operated in special conditions according to user's requirement.

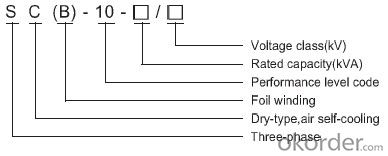

Model designation

Applicable standards

GB6450-1986 Dry-type power transformer

GB/T10228-1997 Technical parameters and requirements for dry-type power transformer

GB/T17211-1998 Guide rules for dry-type power transformer load

GB10237-1998 Insulation level and insulation test for power transformer

GB4208-1993 Casing protection grade(IP code)

JB/10008-1999 6~220KV transformer sound level

JB/T56009-1998 Product quality grading for dry-type power transformer

Performance characteristics

1.Excellent heat dissipation,long thermal life,good overload capacity,without forced air-cooling under a long-term 120% overload and IP45 condition.It can operate for a long time at full load.

2.Extremely high safety fire resistance performance,smoke-free while burning under a temperature as high as 800oC.

3.Extremely high thremal shock resistance capacity.

4.100% water-proof,excellent moisture -proof.

5.Unique winding structure and field strength calculation makes partial discharge impossible.

6.Low loss and significant energy saving effect.Compared with SC9 series of dry-type transformers,the no-load loss falls 10% and load loss falls 5% in average.

7.The insulation material and copper conductor can be dismantled easily and recycled after the service life. Therefore,no pollution will occur.

Notes for placing orders

Transformer type:rated capacity kVA

Number of phases:three-phase single-phase

High voltage: KV/Low voltage:KV

Frequency:50HZ 60HZ

Tapping range:±4×2.5% ±3×2.5% other

Connection group:Yyn0 Dyn11 other

Impedance voltage:4% 6% other

Cooling method: ONAN ONAF

Protecting grade of outer casing:IP00 IP20 IP30 other

Method of incoming and outgoing line:

1.Incoming line to lower part and outgoing line from upper part

2.Incoming line to upper part and outgoing line form upper part

3.Incoming line to upper part and outgoing line form side part

- Q:Hello friendsi need transformer for my project (regulated power supply) i need 220 50hz ac input and 3 volt 50hz out put ac voltage is this possible.what is wattage of that rating transformer?thanks a lot

- Watts rating of the transformer depends on the load. If you have a 10 amp load, for example, that is 10x3 30 watts, so you need a transformer a bit larger than that, say 35 or 40 watts. PS, you will probably not be able to find this transformer available. You may have to settle for a higher voltage, say 5 or 6 volts and reduce it by some other means, or by rewiring the transformer. .

- Q:Hello everyoneA 240-110 stepdown transformer is used with quite a lot of equipement in my home and I have recently become a bit concerned about the effects that they have on the equipement.Thanks to some web page I stumbled across saying that transformers can 'overheat' your equipement etc.And since most transformers aren't made by any big name brands, there really isn't a way to tell if the one in posession is a 'high quality' one or not.So my question is, do transformers actually damage your equipement?Anyone have expertise in this area?Thank you very much.

- All transformers do is change voltage. As long as the equipment you are using is rated for the output voltage of the transformer, there shouldn't be any problems. There is a small possibility that you might get a little bit of humming and line noise from the transformer's windings, and if you're concerned about that, such as with audio equipment or computers, you can use a line conditioner to filter out the noise. I'm not sure what kind of equipment you mean. If you mean equipment that uses large motors or other inductance devices with a low power factor, I have heard that it can cause buckingbut really this is more of a danger to the transformer than the equipment. So, basicallyNO, a transformer isn't going to cause any damage to equipment as long as it's rated for the output voltage of the transformer.

- Q:I use transformers in my circuitry all the time but when a transformer is say a secondary 12v 1a transformer than what does it mean by 1 ampis it that the secondary winding wire will pop after 1 amp doo to the simple thinness of the wire? or that the ohms of the secondary coil, when using iv/r, 112/12so does this tell you that the coil is 12 ohms?please don't give me other information about the transformer just answer the question please.

- It simply means that the maximum safe operating load on the transformer's secondary is 12VA. The maximum safe operating power this transformer can furnish (12 V)*(1A)*(power factor of load's impedance). Power factor is always equal to or less than 1. Power factor cos [arc tan (XL - XC)/(R)]

- Q:GH2 With Guitar.P.S Im a big Transformers fan

- I've played both games, and I'm an admitted Transformers fan since the early '80s. Having said that, you'll get a lot more enjoyment out of GH2. Transformers is a decent game on the consoles, but it seems rushed and isn't quite as polished as it could have been. You'll get more replay value out of GH2.

- Q:Transformer Uk = 4.5% What does it mean?

- Uk represents the transformer impedance voltage, refers to the transformer short-circuit impedance voltage. The impedance of the transformer (now the standard is called: "short-circuit impedance") standard value with a percentage (per unit value) to represent. General small distribution transformer standard value of 4% or 4.5%.

- Q:I just purchased a little halogen spotlight lamp with an Class II transformer that converts 110v-120V to 11.5V. When I put my ears about a 12 inches from the transformer near the wall outlet, I hear a little buzzing or humming noise. Is this normal or is there something wrong?

- A transformer creates a magnetic field that varies at the rate of the line voltage (60 or 50 cycles per second). If there is something in that field that is magnetic, it will be pushed back and forth at that rate, and if it can move, it will create a buzzing sound. Almost all transformers produce a little bit of sound, because the core is made up of layers of magnetic material that are glued together. It's not anything to worry about, just a nuisance.

- Q:We plant transformer plus a total of 16 million households, as a fixed asset depreciation, the financial should be a lot of years more reasonable, is the industrial enterprises, which knows the trouble to help me answer, thank you!

- Transformer is the exchange of AC voltage, alternating current and impedance of the device, the core of the transformer - when the primary coil with AC current, the core (or core) will produce AC flux, the secondary coil induction Out of voltage (or current). Transformer consists of iron core (or core) and coil, the coil has two or more than the winding, which connected to the power supply winding called the primary coil, the rest of the winding called secondary coil. Different types of transformers have the corresponding technical requirements, the corresponding technical parameters can be used. Such as power transformer main technical parameters are: rated power, rated voltage and voltage ratio, rated frequency, operating temperature level, temperature rise, voltage regulation, insulation performance and moisture resistance, for the general low frequency transformer main technical parameters are: change Pressure ratio, frequency characteristics, nonlinear distortion, magnetic shielding, electrostatic shielding, efficiency and so on. Regulations of the People's Republic of China on the Implementation of Enterprise Income Tax Law

- Q:I found out that rising the frequency of the power going to the primary will rise the output/ secondary voltage. So, if I feed a 60 hz 1:1 turn ratio transformer 100volts at 60 Hz (pure sine wave), the output will be 100 volts. but if I increase the frequency to 400 hz and keep the primary voltage at 100V, (pure sine wave) the output/secondary voltage will go above 100 volts. Or no?

- this is yet in a diverse way. enable,Epvoltage around the popular winding; Es voltage around the secondary winding;Np # of turns interior the popular winding;Ns # of turns interior the secondary winding. Then, Ep (Es(Np))/N/s; (25(20))/one hundred500/one hundred 5V Step up transformer, or T turns ratio. T Ns / Np, one hundred/20 5v, Step up transformer. to your f.y.I in case you opt to parent a step down transformer,then, use the formula Es (Ep(Ns))/Np, or TNp/Ns desire this facilitates, persist with the electrical powered industry there's an incredible destiny and a few actual sturdy money to be made in it.

- Q:How does a step down transformer decrease the output voltage but increases the output current? And how does the step up transformer does the opposite thing?

- that one you have to ask the energy saver I think they have the solution.

- Q:Do stores that sells computers, printers, etc. also sell transformers

- Transformers as in the action figures? You can find them at Toys R Us, Wal*Mart, or Target.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SGB10-100-2500-10 H-class insulation three-phase dry-type transformer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords