Sewage Sucking Truck 14m3 SINOTRUK 4x2 QDZ5250GXWZ

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description for QDZ5250GXWZ

Place of Origin: Shandong, China (Mainland)

Model Number: QDZ5250GXWZ

Features for QDZ5250GXWZ

This sewage suction truck is mainly used to suck, transport, unload, and load sewage and sludge existing in the sewer lines and rainwater wells, and it can also be used to suck and transport wastewater, industrial waste oil, and sewage in large factories. Furthermore, sometimes it can even be used to dredge and clean small watercourses.

It is mainly composed of chassis, tank, hydraulic system, high-pressure system, and electrical system.

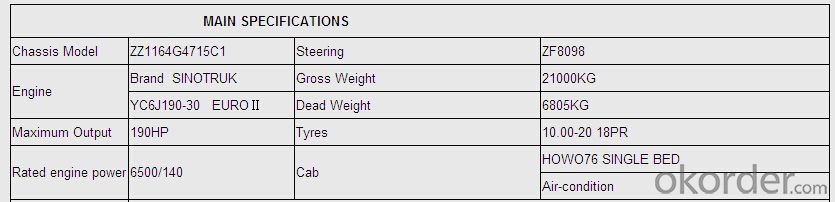

Specification for QDZ5250GXWZ

Pictures for QDZ5250GXWZ

MOQ for QDZ5250GXWZ

Q:What is the advantages of this type of sewage suction truck?

A:Sewage suction truck installs force taking device, transmission shaft, vacuum pump, pressure tank,

hydraulic parts, pipe network system, and equipped with a vacuum pressure gauge,dung window (pipe) device.

9meter long 360 degree swivel suction tube,Hangzhou Weilong vacuum

double pump,model:68/7000,with the anti overflow valve, oil and gas separator, moisture separator, four

way valve.Tank head is 6mm,body size: length 7080mm* macro axis 2400 mm* minor axis1620 mm,four partition boards,

turtle heads,rear head with a 6 Inch disc valve excrement outlet.

- Q:What is the normal speed in the transportation of the concrete mixer

- 12 square concrete mixer, 6 * 4 maximum wheelbase can be installed 12 square 14 square, must use 8 * 4 chassis (don't want to type to copy a bit!) ! Note: 1, the mixer has a low gear, and the novice should pay attention. No more than 30 yards for the car turning. The car itself is in control. 3, pay attention to the car. You must get out of your car to see the road, otherwise you will be miserable. 4, 24 hours to the sleepy at night, but must put the material to the site after finishing Can have a rest. On the way or captain will drive to you ha ha! I am ~, Other things like the road should be familiar, the road is the most important.

- Q:How many layers of steel wire tyres are used in concrete mixers

- For example; 1200 the r20 pr M588 18 1200 is the outer circle size R is the radial tire 20 is the inner circle size, Should be 18PR!!!!!! This is the level of the wire in the tyre. M588 is the symbol of tire tire!! Concrete agitator truck tyres are usually used in 18 levels of steel wire tyres, which is used in 20 levels I'm selling tyres, I hope to help you

- Q:How did the concrete agitate the concrete

- When pouring into the mixing building, the two sides of the car are equal to the stirring bracket, and the first time the mouth is made a mark, so that the next time it will be successful!

- Q:How many cubic meters of concrete mixer transport vehicle

- Existing 3 cubic concrete mixer truck, 3.5 cubic, 4 cubic, 5 cubic, 6 cubic, 8 cubic, 9 12 cubic cubic, 10 cubic, such as specifications, can meet the different needs of customers, chassis choose well-known brands at home and abroad, oil pump, hydraulic motor, deceleration pause with American Eaton, the Italian state, and other well-known brands at home and abroad, to ensure that the vehicle performance is stable, safe and reliable.

- Q:The concrete mixer transporter is running continuously for no more than one hour

- In the tolerable weight, as long as the complete system is not subject to problems (such as heat, oil pressure, stirring, etc.), it can be continuously constructed. The farthest shipping distance I've ever seen is 45 kilometers, no problem at all.

- Q:Why is the concrete mixer turning on the road?

- Because concrete is according to certain proportion with the mixture of the water cement ratio is one of the important factors, the size of water cement ratio directly determine the quality of concrete. In the process of concrete transportation, which is to keep the concrete maintain form without condensation, otherwise it will make concrete loss have building performance.

- Q:s the collapse of four concrete mixer trucks

- Do you mean the concrete can be transported by the concrete mixer? If that's the case, then I say clearly, no, it's a problem that the slump is put in and out of the car. The average slump is 100 to 120mm, and it is better not to transport the concrete transporter, and the best way to do it is to search for it.

- Q:What is the car for concrete

- Concrete cars are called concrete mixers (concrete cars), which are used for transporting concrete concrete trucks for construction purposes. Because of its appearance, it is also commonly referred to as the tian.

- Q:What is the purpose of the concrete mixer

- The main purpose of the mixer is to transport concrete or slurry that is already in a concrete mixer to the construction site. Due to concrete truck mixer mixing tank is adjustable speed rotating stirring, so the concrete mixer truck transport can maximum guarantee stipulated in the delivery distance and time not segregation, coarse aggregate is not settling, maintain good workability; Mixed soil mixer is used for the construction of hybrid stations and large projects. Another concrete mixer is used for carrying water that can carry the same amount of concrete as the payload.

- Q:How many cars do you have for a concrete tanker

- Now the concrete agitator truck is generally measured in the quantity of tank, usually from six square cans to 18 cans, and now it is commonly used in 10-15 cans.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Sewage Sucking Truck 14m3 SINOTRUK 4x2 QDZ5250GXWZ

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products