Semi-transparent Static Film to Protect Electronical Parts

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Semi-transparent Static Film to Protect Electronical Parts

Metal in static shielding film made our of VMPET/PE films for packaging ESD sensitive devices.It is uesed for making ESD static shielding bags ,Thoes films are available with or without printing

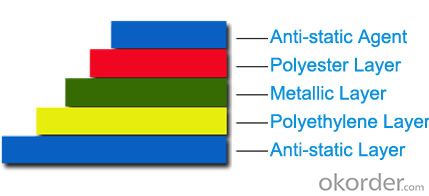

Film construction:

Anti-static Static Shielding Film echnical Data

| Electrical Properties | Typical Values | Test Method |

| Surface Resistance | ANSI/ESD STM 11.11 | |

| Interior | <10E11ohms | |

| Exterio | <10E11 ohms | |

| Metal | <100 ohms | |

| Static Shielding | <15 nJ | ANSI/ ESD STM11.31 |

| Static Decay | <0.03 seconds | EIA 541 |

| Charge Generation | < 100 volts | ** 15kV and 12% RH |

| Physical Properties | ||

| Material Thickness | 3.6mil+/-10% | ** |

| Puncture Resistance | ≥10.0lbs | MIL-PRF-81705D |

| Tensile Strength | > 4500 psi MD/TD | ASTM D882 |

| Seam Strength | No separation | MIL-PRF-81705D |

| Optical Density | Opaque(Sliver) | ASTM D-882 |

| Heating sealing Conditions | 375°F 0.5sec.60 PSI | ** |

| MVTR | < 0.02grams/100sq. in/day | ASTM F-1249 |

| Appearance | No tears,holes,sctratches,etc. | |

| Chemical Properties | .Compliant to ROHS,REACH, | |

| Halogen free ETC requirement | ||

| Amines/Amides | Not detected | FTIR |

Antistatic Static Shield Film Roll Film specifications:

Width:450-1300mm

Thickness:0.07-0.17mm

Printing: Standard with ESD requirements,approx 50X50mm

Yellow. Date code(YYMM).

About us :

Btree is China's top 5 supplier of Static Shielding Bags and Moisture Barrier Protection. We offer a full range of

ESD Packaging solutions. Speak to our friendly team or request a brochure.

ESD Moisture Barrier Film Technical Data

| Electrical Properties | Typical Values | Test Method |

| Surface Resistance | | ANSI/ESD STM 11.11 |

| Interior | <10E11ohms | |

| Exterio | <10E11 ohms | |

| Metal | 100 ohms | |

| Static Shielding | <15 nJ | ANSI/ ESD STM11.31 |

| Static Decay | <0.03 seconds | EIA 541 |

| Charge Generation | < 100 volts | ** 15kV and 12% RH |

| Physical Properties | | |

| | | |

| Material Thickness: | 4.0mils+/-10% | |

| Puncture Strength | 10.0 lbs | MIL-PRF-81705D |

| Seam Strength | No separation | MIL -PRF-81705D |

| Heating sealing Conditions | | |

| Temperature | 300°F -400 °F | |

| Time | 0.6 -4.5seconds | |

| Pressure | 30 – 70 psi | ASTM D882 |

| Tensile Strength | >3,500 psi MD/TD | ASTM F-1249 |

| Water vaporTransmission (@100°F&90%RH) | <0.006grams/100 sq in/day | |

| | | |

| Visual inspection | No tears,holes,sctratches,etc. |

Produce progress:

Packaging

- Q:Dried fish vacuum packaging packing bag can not puncture

- If the choice of transparent vacuum packaging bag can also, without aluminum foil bags, good quality effect.

- Q:How can the labels affixed to the bags be removed quickly?

- Use the hair dryer to adjust the hot air to the label. When the label is heated, the glue will melt so that it can be torn off easily. This method is suitable for metal and plastic tools, characterized by quick.

- Q:How do I remove the self-adhesive label affixed to the plastic bag?

- On the label with wind, a few minutes to unveil the label, the label will fall together with adhesive. Even at the stubborn stickers with traces of essential balm, and fingernails pull, usually can quickly clean up the traces.

- Q:What material should be used for transparent packing bags? How many cents do you want?

- Generally Po (polyolefin) material, you can also use PE (polyethylene) material, PP (polypropylene) material, to see your specific needs

- Q:What are the types of composite packaging bags?

- Folding containerA large volume of transport package, the weight of more than 1 tons. The top of the container is usually equipped with metal hangers or rings, which is convenient for lifting and transporting of forklifts or cranes. When discharging, it is possible to open the discharge port at the bottom of the bag and unload the cargo conveniently. Suitable for shipment of granular or powdery articles.Container bags are usually made of polyester fibers such as polypropylene and polyethylene. Because the container loading and unloading of goods, transportation is very convenient, improve handling efficiency, in recent years made shoes soon.

- Q:What does "TM" mean in a food package?

- TM is common in foreign trademarks. It is the abbreviation of "trade mark" in English. "Trade mark" means "commercial mark" in Chinese, so "TM" means "trademark""

- Q:What material is the surface of the packing bag such as instant noodles, pickled mustard tuber, small bread and so on? Why should we add this layer?

- First, it is easy to heat seal, otherwise only aluminum foil can not be sealed;Two, high barrier plastic film preservation effect is also very good, can increase its number of layers, reduce aluminum foil thickness, thereby reducing costs

- Q:How about the material difference of food packaging bag?

- But the packing bag is not a single material, generally the inner layer is PE, the outer layer is PA, and the middle may be EVOH, or PVDC, etc.Yes, the aluminized film is used

- Q:Why a lot of the packaging bag surface is silver foil?

- Because of the use of aluminum foil can effectively prevent light barrier light, plastic packaging and direct food through accelerated food spoilage.

- Q:What's the packing of the air in the food package?

- Carbonated drinks are mostly filled with carbon dioxide gas CO2, and its own drinks are carbon dioxide ingredients in the majority, with CO2 replacement of the air, but also for the preservation of the product, to ensure the taste, but also improved the shelf life.In addition, some food packaging is filled with a certain proportion of mixed gas, may be O2+CO2+N2, N2+CO2, O2, +CO2. This is also based on the needs of different enterprises, different customers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Semi-transparent Static Film to Protect Electronical Parts

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords