Self priming centrifugal diesel engine four wheel trailer pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction

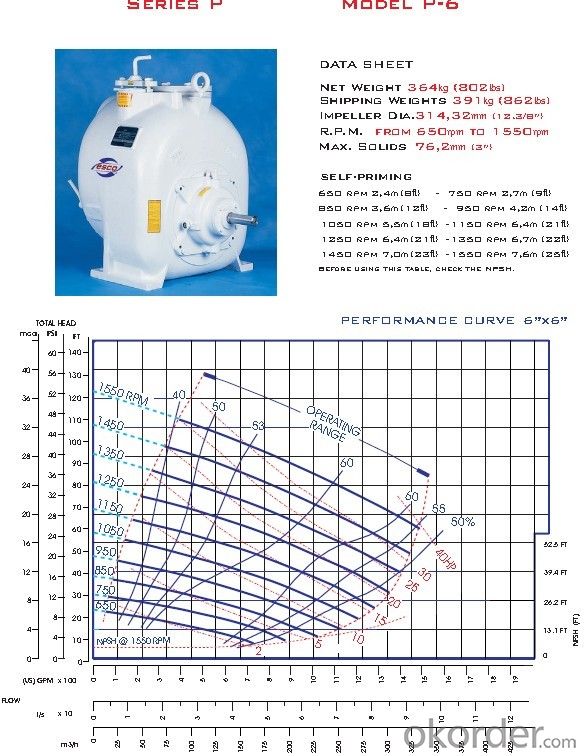

Main datas:

Capacity( flow rate) :35 ~ 310m3/h

Head :5~58 m

Speed:850 ~ 1950rpm

Impeller diameter:317.5mm

Pump weight:413kg /437kg

Power:5 ~ 75 hp

Advantage :

Big pump body pass 31.75mm solid ,high suction head 7.6 m

Convenient repair and clean (a person ten minutes)

Removable cover plate ,replaceable wear plate

OEM ,L/C ,TT ,O/A ,D/P,D/A and so on

CE ,TUV .ISO

NAME: Self priming centrifugal diesel engine four wheel trailer pump

Standard Self-Priming pump units are available for Solids Handling or Clear Liquid service. Typical mounting configurations are Engine Driven for Skid or Trailer Mounted packages and Frame Mounted Electric Driven. Pumps also are available in a variety of different metallurgies.

1) Main Character

1.Beautiful shape and fine structure,reliable performance.

2.With strong capacity of delf priming, no need to equip with flap valve.

3.Non-clog, and with powerful capacity of passing big solid..

4.The hole can make sure that stronger sewage can be cleaned quickly when pump is jammed.

5.The unique lubrication oil mechanical seal cavity makes the performance more reliable.

6.Special check valve structure can make the pump working quickly.

7. When working, the gas and liquid works together .

8. Low rotary speed,reliable operation,long time usage, easy to maintenance.

9.Advanced pressure protector make pump the pump work safe.

2) Application Area

1. Municipal project, sewage project, instruction project.

2.Uptown,hospital, hotel sewage transportation.

3.Classification of municipal sewage factory treatment and concentrate system engineering.

4. Factory and contaminated water delivery.

3) Industries Served

♦ Construction | ♦ Industrial | ♦ Municipal |

♦ Agricultural | ♦ Mining | ♦ Dewatering |

♦ Industrial Waste | ♦ Sewage | ♦ Oil Field |

♦ Petrochemical | ♦ Paper Mills | ♦ Processing |

4)Parameter

| 1.Inlet/Outlet | 2''(50mm), 3''(75mm), 4''(100mm), 6''(150mm), 8''(200mm), 10''(250mm), 12''(300mm) | |

| 2.Impeller Diameter | 158.74mm-457.2mm | |

| 3.Rotary Speed | 550RPM-2150 RPM | |

| 4.Flow Rates | 8m3/h-1275m3/h | 20GPM-5500GPM |

| 5.Head | 6m-63m | |

| 6.Horsepower | 1HP-125HP | |

| 7.N.W | 92KG-998KG | |

| 8.G.W | 114KG-1066KG | |

| 9.Solid Passing | 20.63mm-76.2mm | |

| 10.Material | Cast Iron, ADI, CD4MCU, 316 SS, Alloy 20, C276. | |

| 11.Diesel Driving | Water cooled or air cooled | |

| 12.Method of Connection | Self-priming pumps are available as basic units or may be flex-coupled, V-belt driven or engine mounted. | |

| 13.Drive Variation | Cummins, Deutz, Ricardo, Perkins or Chinese Diesel, Electric Motor | |

| 14.Skid Mounted on Trailer | 2 or 4 wheels Trailer/Trailor,Cart | |

| 15.Package | Exporting plywood case | |

| 16.Certification | CE , ISO9001:2008 ,TUV | |

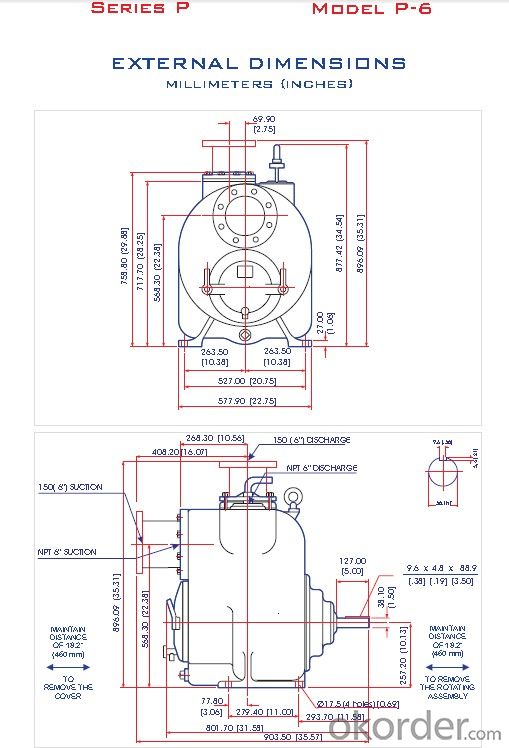

5) Mounting Configuration

♦ Frame Mounted

♦ Base Mounted Electric Driven

♦ Engine Driven SAE Mounted

♦ Engine Driven Skid or Trailer Packages

♦ Horizontal or Vertical V-Belt Driven

Prameter

5) Mounting Configuration

♦ Frame Mounted

♦ Base Mounted Electric Driven

♦ Engine Driven SAE Mounted

♦ Engine Driven Skid or Trailer Packages

♦ Horizontal or Vertical V-Belt Driven

Samply available: 7~10days.

Qty: 1pc, only pump head is provided.

Price: US$100~200

OEM is welcome

OEM expierence: more than 10 years.

Countries: Germany, U.S.A, Spain, Italy, United Kingdom etc

Warranty: the whole pump is guaranteed within 1 year, the pump's spare parts are guranteed for 3 months from the date of delivery.

For more information, please do not hesitate to contact me.

The information should be including inquiry as following:

1.Pump's flow rate

2.Pump's Head (Pressure)

3.Driven Mode: By electric motor or diesel engine or bare shaft etc

4.Power and rotary speed

5.Suction lift for self priming pump

6.Temperature of liquid if you can provide

Upon the receipt of the pump's parameter, we can send our quotation to you within 24 hours.

Or the condition of pump station would be provided.

♦FAQ:

1. Q: Can I know more about your products?

A: Pls view our website: www.lanco.cc.

2. Q: What’s your MAQ of this item?

A: 1~2PCS

3. Q: What is the lead time?

A: 10~30 days after receiving your payment,depends on pumps.

4. Q: where is your loading port?

A: Ningbo, China port

5. Q: Are you a manufacturer or trading company

A: We are a manufacturer specialize in water pump and other pumps more than 20 years.

For more information, please contact me.

- Q:Advantages and disadvantages of centrifugal pumps?

- The uniform liquid no pulse phenomenon.(2) shortcomingsBefore running, the pump must be filled with liquid.For the supply of small flow, large pressure head inappropriate, inefficient and limited.Encountered imperfect design or operation is not at the time, such as milk, it is easy to produce foam, affecting the next process production.The installation is wrong. There will be "Qi tie" phenomenon.The efficiency is also lower than the reciprocating pump.The sources of knowledge are absolutely reliable!!!!

- Q:If the suction pump does not have enough suction range, you need to add a vacuum pump to increase the suction stroke. How do you install the suction pipe of the vacuum pump? Water pump impeller is not closed, it is normal that the vacuum pump is unable to pump suction pipe to a vacuum, is it because the water pump outlet pipe connected to the role of the check valve? But the water pump, outlet pipe, check valve sealing performance can achieve the function of non leakage?

- The role of the check valve:"[the water pump impeller is not closed" refers to the pump suction pump before the water without water inlet pipe and water outlet pipe gas should be connected] is a connector, a connector, still can make the level surface, in order to prevent the water flow along the pipe, until it reaches the level of the flush, then increased check valve.

- Q:Working principle and structure of external gear pump

- External gear pump is the most widely used gear pump, the general gear pump usually refers to the external gear pump. Its structure as shown in the diagram, there are mainly driving gear, driven gear, pump body, pump cover and safety valve and so on. The seal space of pump body, pump cover and gear is the workshop of gear pump. The wheel shafts of the two gears are respectively arranged in the bearing holes on the two pump cover, and the driving gear shaft extends out of the pump body and is driven by the motor to rotate. The external gear pump is simple in structure, light in weight, low in cost, reliable in operation and wide in application. When the gear pump works, the driving wheel rotates with the motor and drives the driven wheel to rotate

- Q:How many concrete pump tube diameter

- The pump is generally divided into 125 and 150 two, the inner diameter is 125mm and 150mm. And the two kinds of each have high and low pressure points. Low pressure type type 125 pump for the pipeline diameter is phi 133,

- Q:What is the difference between the ground pump and the pump in the commercial concrete?

- What you should say here is the concrete pump.Ground pump: the pump will be placed in a position on the site, the pipeline will be sent to the construction of concrete surface,

- Q:What is the distance between the pump and the wall?

- What do you mean by that? If your pump is parallel to the wall! Then, the wall of the pump near the wall is usually 500mm. This is an empirical data, considering the import pipe length, pump maintenance and motor heat dissipation and other aspects of the situation to determine. Dozens of pumps installed in our company are placed in this size! Hope to be of help to you.

- Q:5 floor water pressure is too low, what kind of water pump is better?

- Installed pump flow, lift did not meet the requirements, this will need to re type selection, calculation;

- Q:Suction stroke and lift of water pump

- Lift pump lift pump can lift refers to the height, usually expressed in H, the unit is m. centrifugal pump lift to the impeller center line, divided by two parts. The vertical height from the pump impeller centerline to the water surface, the water pump to suck water up to the height, called water head, referred to as suction pump impeller; from the center line to the vertical height of the water tank, the water pump can put pressure on the height, called water pressure head, referred to as the pressure. The pump head = + suction head pressure water head should be pointed out that the nameplate marked head refers to the pump itself can produce lift, it is not with the pipe flow friction resistance caused by the loss of lift. In the selection of water pump, attention can not be ignored. Otherwise, will be pumping Sheung Shui.

- Q:Must the water pump in the tank be all soaked in water?

- Need a submersible pump in the water, but it is not entirely like this, I have to work for a long time no problem in water, but there is a problem you should pay attention to the water pump, at least in half, or stop when the smoke is not on water.

- Q:What are the advantages and disadvantages of the pump control system and valve control system in the hydraulic system? How to choose in the project?

- Pump control system is generally used for closed systems, the flow of the oil pump changes to control the motor or cylinder actuator action. The utility model has the advantages that the principle is simple, and the power of the engine can be fully utilized. The disadvantage is that the calorific value of larger, relatively poor precision.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Self priming centrifugal diesel engine four wheel trailer pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches