Self-Climbing Type and Mobile Type Concrete Placing Boom

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

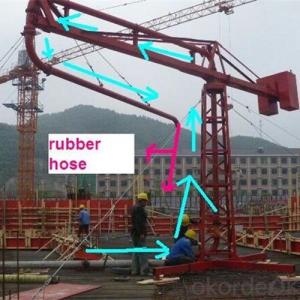

Mobile Concrete Placing Boom

A mobile concrete placing boom can be put on any places that are rigid and flat according to job requirements.

Features

The placing boom has a Z&R-shaped boom assembly with three foldable sections, which can swing through 360 degrees while luffing, folding/unfolding, thus allowing it to place concrete to form walls, pipes, columns, piles and other vertical structures without confined placement areas.

The boom assembly’s luffing; folding/unfolding and swinging are carried out hydraulically with buttons. The hydraulic and electrical system feature overload protectors, flow controls, alarms, phase sequence protectors and so on, which ensures the placing boom to have reliable performance, easy and smooth operation, and high safety.

Featuring compact structure and lightweight, the placing boom can be completely lifted and transferred to any suitable places for concrete placement, such as floors, platforms, simply-structured racks or even trailers. It does not need to be fixed while working. In addition, it can be lifted off the placement sites when it is not needed, which leads to no disturbance to other jobs and easy maintenance.

It is well fit for the construction of different floors and for complicated jobsites without being influenced by the size and shape of floors.

Brief Technical Description

Mobile Concrete Placing Booms | HGY13 | HGY15 | HGY17 | ||

Horizontal Reach(m) | 13 | 15 | 17 | ||

Length of End Hose(m) | 3 | 3 | 3 | ||

Rotation(m) | 360 | 360 | 360 | ||

Elevation Angle (°) | 2~84.4 | 0~90 | 0~90 | ||

Hydraulics Output(kw) | 4 | 4 | 5.5 | ||

Hydraulics Pressure(Mpa) | 20 | ||||

Total Weight(t) | Without counterweight | 2.7 | 3.2 | 4.94 | |

Counterweight | 1.6 | 2.2 | 2.1 | ||

Self -Climbing Placing Boom

A climbing concrete placing boom mainly consists of the tower body, climbing frames, slewing mechanism, upper-lower pedestals, boom assembly, hydraulic system, electrical system, etc., and is suitable for the construction of high-rise buildings. It is fixed in the lift shafts or floor openings and climbs up by means of its climbing system or a tower crane, providing enhanced efficiency and quality of concrete placement and saving labor.

a. Self-climbing in the lift shafts: The placing boom climbs up along the lift shaft with the rising of the floors, with horizontal reaches of 28m and 24m.

b. Self-climbing in the floor openings: The placing boom climbs up along the floor openings with the rising of the floors, with horizontal reaches of 32m, 28m, 24m and 17m.

Tower crane-aided climbing in the floor openings(Model HGY17)The HGY17 places concrete by fixing it in the prepared openings in the floor plates.

When the placing boom is required to climb up, lift it up to a higher floor by means of a tower crane so as to fix its tower body in the prepared openings in the floor plates with the help of its climbing frames. In case of large square concrete placement, more tower bodies can be mounted in different openings to match with the boom assembly that is disassembled from one location and then lifted to the designated location.

This type of placing boom is unable to climb up by itself, but with the help of a tower crane it can perform as a self-climbing one or a mobile one, and has the following advantages:

Prepared openings can be built in different locations according to job requirements to make full use of the length of boom sections.

Self-Climbing Placing Booms | HGY 17 | HGY24 | HGY28 | HGY32 | |

Horizontal Reach(m) | 17 | 24 | 28 | 32 | |

Length of End Hose(m) | 3 | 3 | 3 | 3 | |

Stationary Height(m) | 11 | 21 | 21 | 21 | |

Rotation(°) | 360 | 360 | 360 | 360 | |

Elevation Angle(°) | -4~90 | -4~90 | -4~90 | -4~90 | |

Hydraulics Output(kw) | 5.5 | 11 | 11 | 18.5 | |

Mode of Drive | Hydraulic | Hydraulic | Hydraulic | Hydraulic | |

Mode of Operation | Radio/Cable/Control panel | ||||

Pipeline Diameter(mm) | 125 | 125 | 125 | 125 | |

Scope of Application of the Equipment

The concrete placing boom is a concrete placer for combined use with a concrete pump in concrete placement operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This equipment can only be used in concrete construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The equipment is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Product Advantages:

OKorder's Concrete placing boom Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (20-40 days after receiving deposit)

Reliable performance

Easy and smooth operation

High safety.

· Professional Service

· Competitive pricing

Q1: How to control the Placing Boom ?

A1: The control system has two control modes for the user's selection: wireless remote control, and panel control.

Q2: How do we guarantee the quality of our Placing Boom?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Concrete Placing Boom according to customers request?

A4: Yes, we can produce Concrete Placing Boom according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q:What is a fixed concrete distributor?

- Concrete distributing machine: special concrete pouring equipment for construction, design and production of railway beam yard and nuclear power plant

- Q:How to maintain the concrete spreader?

- Four screw high precision quantitative cloth is adopted, and the error of cloth quantity is less than 2%. According to the field process, the traveling speed and the cloth speed are stepless flexible adjusted

- Q:what's the difference between the fabric pump and boom pump?

- Boom pump itself has pumping function, cloth machine needs to buy drag pump matching use

- Q:What are the weekly inspection items for concrete spreader?

- Check the wear of the pipe, the arm thickness is less than 2mm, should be replaced in a timely manner

- Q:What are the benefits of concrete handling machines?

- The construction area of the crane pipe can not be reached, and the concrete distributor can be used instead

- Q:What are the specifications of concrete spreader?

- Rotary: rotary, rotary and double rotary bearings; is a kind of new construction machinery and supporting the use of concrete conveying pump tube

- Q:What are the monthly inspection items of the movable concrete spreader?

- Check whether the rotary limiter works properly and check the coupling of the motor

- Q:What are the acceptance items of concrete spreader?

- The transmission mechanism of the protective cover, etc., each part is firmly connected cloth machine should maintain a certain distance with high voltage and electrical lines, the end of the pouring hose must fasten safety flies, prohibit the use of the length of more than 3 meters water column end hose, hose into the column shall be poured concrete, in strict accordance with the scope of work cloth machine. Work fabric machine under arms are not allowed to stand

- Q:How to install and use the distributor?

- Install the fuse according to the electricity consumption. No steel, aluminum or zinc wire shall be used instead of the fuse.

- Q:How to distinguish tower type distributor and general distributor?

- No frame structure. Its stability and service life are all behind the tower cloth machine

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Self-Climbing Type and Mobile Type Concrete Placing Boom

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords