Seamless Steel Pipe with Best Price and High Quality/Hot Selling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DETAILS

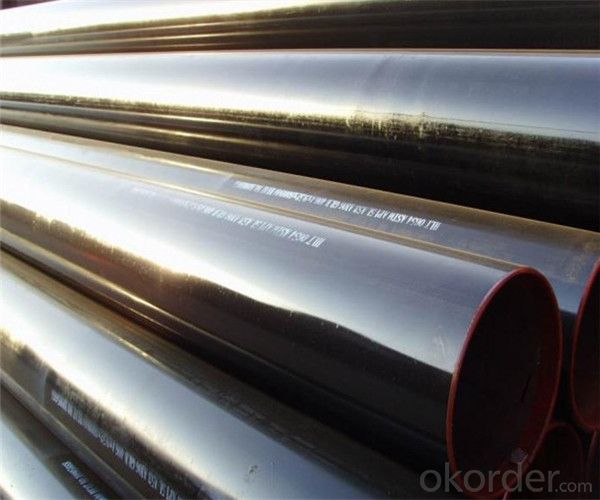

1.Structure of Seamless Steel Pipe Description:

A large amount of Seamless Steel Pipes is offered to the clients at cost effective rates. These pipes are extremely durable, resistant to corrosion and have high tensile strength. Our pipes are used in nuclear plants, power plants, refineries and construction industry across the country. Furthermore, we are capable of providing these seamless pipes to the clients in bulk quantity.

2.Product pictures

3.Packaging & Delivery:

| Packaging Details: | Seaworthy packages, bundles wrapped with strong steel strip |

| Delivery Detail: | 15-30 days after received 30% TT |

4.Seamless Steel Pipe Specification:

| Standard: | GB, DIN, ASTM,ASME, ASTM A106-2006, ASTM A53-2007 |

| Grade: | 10#,20#, 45#, 16Mn |

Thickness: | 8 - 33 mm |

| Section Shape: | Round |

| Outer Diameter: | 133 - 219 mm |

| Place of Origin: | Shandong, China (Mainland) |

| Secondary Or Not: | Non-secondary |

| Application: | Hydraulic Pipe |

| Technique: | Cold Drawn |

| Certification: | API |

| Surface Treatment: | factory state or painted black |

| Special Pipe: | API Pipe |

| Alloy Or Not: | Non-alloy |

| Length: | 5-12M |

| Outer Diameter: | 21.3-610mm |

5.FAQ of Seamless steel pipe:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust.

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q:How are steel pipes protected against rust and corrosion?

- Steel pipes are protected against rust and corrosion through various methods such as applying protective coatings, galvanizing, and cathodic protection. These measures create a barrier between the steel surface and moisture or corrosive substances, ensuring the longevity and integrity of the pipes.

- Q:How are steel pipes coated for protection?

- Steel pipes are commonly coated for protection through a process called galvanization. This involves immersing the pipes in a bath of molten zinc, creating a protective layer that prevents corrosion and extends their lifespan. Additionally, other methods such as epoxy coatings or polyethylene wrappings can be used to provide additional protection against external factors.

- Q:How do steel pipes compare to other types of piping materials?

- Steel pipes are highly durable and have excellent strength, making them superior to other types of piping materials in terms of longevity and resistance to extreme conditions. They are also more cost-effective, as steel pipes require less maintenance and have a longer lifespan. Additionally, steel pipes have better corrosion resistance, making them ideal for various applications, especially in industries where chemical exposure is common.

- Q:Which is better, galvanized steel pipe or stainless steel?

- Most of the use requirements are to maintain the original appearance of the building for a long time. In determining the type of stainless steel to be chosen, the main consideration is the aesthetic standards required, the corrosivity of the atmosphere in the area, and the cleaning system to be adopted. However, other applications increasingly seek only structural integrity or watertightness. For example, the roof and side walls of industrial buildings. In these applications, the construction cost of the owner may be more important than the aesthetic, the surface is not very clean can also. The use of 304 stainless steel in a dry indoor environment is quite effective.

- Q:What are the uses of seamless steel tubes?

- A large number of pipes used for conveying fluids, such as pipelines for transporting petroleum, natural gas, gas, water, and certain solid materials.

- Q:What are the specific differences between flexible pipes and rigid pipes?

- The rigid waterproof sleeve is used in the wall of the building which does not need to bear the vibration and expansion deformation of the pipe, and the wall thickness is 200mm in general;Flexible waterproof sleeve is mainly applicable to the wall of buildings with seismic requirements, pipeline vibration and expansion deformation, and strict waterproof requirements, and the wall thickness is 300mm

- Q:What are the different methods of pipe protection for steel pipes?

- Steel pipes can be protected in various ways, each with its own purpose and level of defense. Some commonly used methods include: 1. Coatings: To shield steel pipes from corrosion and environmental factors, coatings are applied to the outer surface. These can be paints, epoxies, or polymers that create a barrier between the pipe and its surroundings, preventing contact with corrosive elements. 2. Wrapping: Another method involves using materials like tape or shrink wrap to cover the steel pipe, providing a physical barrier against moisture, chemicals, and corrosive substances. Wrapping is often combined with coatings to enhance protection. 3. Cathodic Protection: This electrochemical method safeguards steel pipes from corrosion by connecting them to a sacrificial anode, typically made of zinc or magnesium. The anode corrodes instead of the pipe, preventing deterioration. It is commonly used for buried or submerged pipelines. 4. Thermal Insulation: Steel pipes exposed to extreme temperatures can be protected with thermal insulation. Materials like foam or mineral wool are applied around the pipe to minimize heat transfer. This is particularly important for pipes carrying hot fluids or in harsh weather conditions. 5. Vibration Dampening: Vibrations can damage steel pipes by causing stress and fatigue. To counter this, techniques like vibration damping pads or supports and clamps can be used. These methods absorb and dissipate the energy generated by vibrations, reducing the risk of pipe failure. 6. Concrete Coating: For pipelines installed underwater or in highly corrosive environments, concrete coating is often employed. A layer of concrete or cement-based mortar is applied to the steel pipe, providing both mechanical protection and resistance to corrosion. Choosing the appropriate method of pipe protection depends on the specific application, environmental conditions, and desired level of defense. Regular inspection and maintenance are also crucial in maintaining the long-term integrity of steel pipes.

- Q:How are steel pipes connected or joined together?

- Steel pipes are commonly connected or joined together through welding, threading, or using pipe fittings such as couplings, flanges, or unions.

- Q:How are steel pipes protected against internal corrosion?

- Steel pipes are protected against internal corrosion through various methods, such as applying protective coatings or linings to the inner surface of the pipes. These coatings act as a barrier between the steel surface and the corrosive elements present in the transported fluids. Additionally, cathodic protection can be employed, where a sacrificial anode or an impressed current system is used to prevent corrosion by diverting the electrical current away from the steel surface. Regular maintenance and monitoring are also crucial to ensure the ongoing protection of steel pipes against internal corrosion.

- Q:What's wrong with the 3PP anticorrosive steel tube?

- That is, polypropylene corrosion resistant coating of steel pipe, the biggest feature of this anti-corrosion coating is good heat resistance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Seamless Steel Pipe with Best Price and High Quality/Hot Selling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords