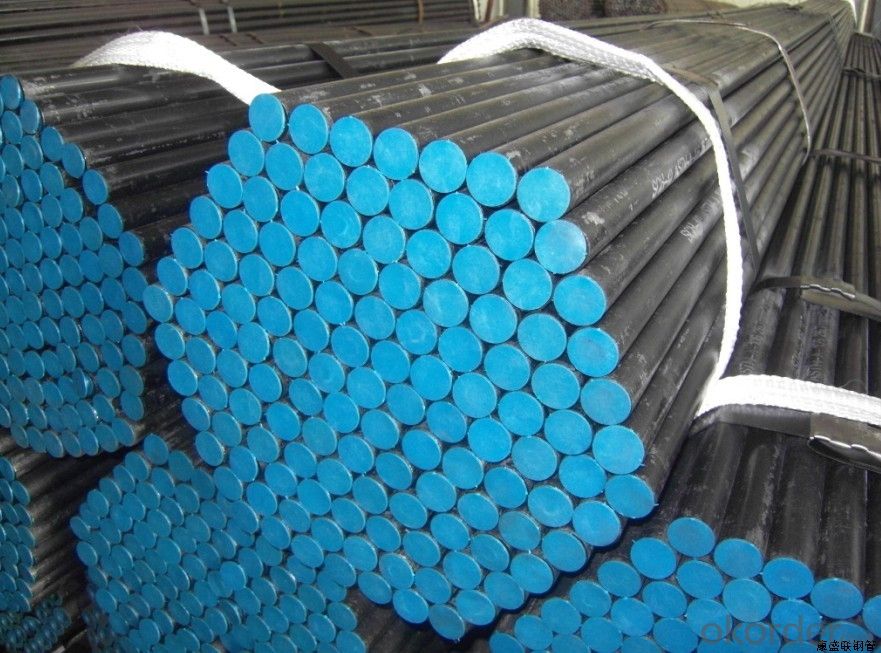

Seamless Boiler Tube

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Descriptions :Seamless Boiler Tube

1.O.D:13.7mm~610mm

2.W.T:2.34mm~30mm

3.Length:5-11.8m

4.Certificate:API 5L,BV

Description | Size | Typical Steel Grade | Standards | Typical Applications | |

OD(mm) | WT(mm) | ||||

Medium and low pressure boiler tube and pipe | 14~720 | 2.0~120 | 10 | GB 3087 | Wall tube, header, steam pipe formedium and low pressure boiler tube and pipe |

20 | |||||

High pressure boiler tube and pipe | 14~720 | 2.0~120 | 20G, 25MnG, 15MoG 12CrMoG, 15CrMoG 12Cr2MoG, 12Cr1MoVG | GB 5310 | Wall tube,header, Steam pipe under the working pressure ≥9.8MPa, Temperature 450~650℃ |

SA106A/B/C | ASME SA106 | ||||

SA179 | ASME SA179 | ||||

SA192 | ASME SA192 | ||||

T1/T1a | ASME SA209 | ||||

SA210A1/C | ASME SA210 | ||||

T2/P2, T5/P5, T9/P9, T11/P11 , T12/P12, T22/P22, T91/P91 | ASME SA213 ASME SA335 | ||||

P195/235/265GH, 16Mo3 13CrMo4-5, 10CrMo9-10 15NiCuMoNb5-6-4 | EN 10216 | ||||

St35.8、St45.8, 15Mo3, 13CrMo44, 10CrMo910 | DIN 17175 | ||||

STPG370, STPG 410 | JIS G 3454 | ||||

STPT370, STPT 410 | JIS G 3456 | ||||

STBA12, STBA22, | JIS G 3462 | ||||

Dalipal Company is one of the most famous enterprises of china professionally producing pipeline and oil casing.We can supply API 5CT series of pipeline and oil casing with all kinds of specifications and materials.We have first-class production equipment and technology.

- Q:How are steel pipes used in plumbing?

- Steel pipes are commonly used in plumbing applications due to their durability, strength, and resistance to corrosion. They are used to transport water, gas, and other fluids from one place to another in a plumbing system. Steel pipes are often found in underground water supply networks, as well as in buildings for conveying hot and cold water, drainage, and venting systems. Additionally, steel pipes are also utilized for connecting fixtures, such as sinks, showers, toilets, and appliances, ensuring a reliable and long-lasting plumbing infrastructure.

- Q:How are steel pipes used in the construction of telecommunications towers?

- Steel pipes are used in the construction of telecommunications towers as they provide structural support and stability. They are used as the main framework for the tower, forming the vertical columns, horizontal bracing, and diagonal supports. These pipes are capable of withstanding heavy loads, high winds, and other environmental factors, ensuring the tower's durability and longevity. Additionally, steel pipes allow for easy installation and maintenance of antennas, cables, and other telecommunications equipment.

- Q:Can steel pipes be used for stadium construction?

- Yes, steel pipes can be used for stadium construction. Steel pipes offer several advantages that make them suitable for this purpose. Firstly, steel pipes are strong and durable, making them capable of withstanding heavy loads and providing structural stability to large structures like stadiums. They have high tensile strength, which means they can resist bending or breaking under pressure. Additionally, steel pipes are resistant to corrosion, which is crucial for outdoor structures like stadiums that are exposed to various weather conditions. Their resistance to rust and other forms of degradation ensures the longevity of the stadium. Furthermore, steel pipes are versatile and can be easily fabricated into different shapes and sizes, allowing for customized designs and efficient installation. Moreover, steel pipes offer cost-effectiveness in stadium construction. They can be easily produced in large quantities, making them readily available and affordable. The ease of transportation and installation of steel pipes also contributes to their cost-effectiveness. Another advantage of using steel pipes for stadium construction is their sustainability. Steel is a recyclable material, and using steel pipes promotes environmental responsibility. The recyclability of steel reduces the demand for new materials and minimizes waste. In summary, steel pipes can indeed be used for stadium construction due to their strength, durability, resistance to corrosion, versatility, cost-effectiveness, and sustainability.

- Q:How are steel pipes used in hydroelectric power plants?

- Steel pipes are used in hydroelectric power plants to transport water from the reservoir to the turbines. These pipes are able to withstand high pressure and ensure a reliable flow of water, which is crucial for the efficient operation of the turbines. Additionally, steel pipes are also used for the construction of penstocks, which control the flow of water and direct it towards the turbines.

- Q:How are steel pipes used in the chemical industry?

- Steel pipes are extensively used in the chemical industry for various applications, including transportation of chemicals, gases, and liquids. They are highly durable, corrosion-resistant, and can withstand high pressure and temperature conditions. Steel pipes are used in chemical plants for the transfer of raw materials, intermediate products, and final products within the production process. They are also employed for the distribution of utilities such as water, steam, and compressed air. Additionally, steel pipes are utilized for the construction of storage tanks, reactors, and other equipment in the chemical industry due to their strength and reliability.

- Q:What is the maximum pressure that steel pipes can withstand?

- The maximum pressure that steel pipes can withstand varies depending on factors such as the steel grade, pipe dimensions, and wall thickness. However, steel pipes are known for their high strength and durability, allowing them to withstand pressures ranging from a few hundred to several thousand pounds per square inch (psi).

- Q:How are steel pipes used in the manufacturing of desalination plants?

- Steel pipes are used in the manufacturing of desalination plants for various purposes, such as transporting seawater, brine, and freshwater through different stages of the desalination process. They are also used for the construction of pipelines, intake systems, and discharge outlets, ensuring durability, corrosion resistance, and efficient water flow in these critical systems.

- Q:Can steel pipes be used for structural applications?

- Yes, steel pipes can be used for structural applications.

- Q:What is the difference between standard wall thickness and extra-strong wall thickness steel pipes?

- The main difference between standard wall thickness and extra-strong wall thickness steel pipes lies in their thickness and durability. Standard wall thickness pipes have thinner walls and are suitable for most general applications, while extra-strong wall thickness pipes have thicker walls and are designed for heavy-duty or high-pressure applications. These extra-strong pipes offer enhanced strength and resistance, making them more reliable and suitable for handling extreme conditions or demanding projects.

- Q:Do steel pipes expand or contract with temperature changes?

- Steel pipes expand when subjected to an increase in temperature and contract when exposed to a decrease in temperature. This phenomenon is a result of the thermal expansion and contraction properties of steel, which is a characteristic of most materials. When steel pipes are heated, the molecules within the metal gain energy and vibrate more vigorously, causing them to move apart and expand in size. Conversely, when the temperature of the steel pipes decreases, the molecules lose energy and move closer together, resulting in a contraction or shrinkage in size. It is important to consider these thermal expansion and contraction properties of steel pipes when designing and installing them, as failure to account for these changes may lead to structural damage, leaks, or other issues.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Seamless Boiler Tube

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords