SDIC Chlorine Powder Disinfectant Dichloroisocyanurate Sodium

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 1800 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SDIC

Introduction:

CNBM--SDIC White powder or grain with chlorine odor . It is a strong oxidant and chlorate agent and can dissolved in water easily . Its aqueous solution assumes weak acidity and the active chlorine in its dry products lose little when it is stored for a long time at the atmospheric temperature .

Specification:

Chemical Name | Sodium Dichloroisocyanurate | |

Molecular Formula: | C3O3N3HCL2NA | |

Molecular Weight: | 220.96 | |

CAS Number: | 2893-78-9 | |

Product | 60% | 56% |

Available chlorine(%,min) | 60 | 56 |

Moisture content(% max) | 5 | 8 |

PH Value(1% solution) | 6-7 | 6-7 |

Particles Size:

Mesh | 5~8 | 8~30 | 20~40 | 20~60 |

Main usage:

this products can effectively kill various germs, fung uses and viruses, specially A&B type hepatitis viruses. It is effective on killing algae, decolorizing cleaning water or bleaching .It can be widely used for epidemic prevention, livestock farming , industry and agriculture.

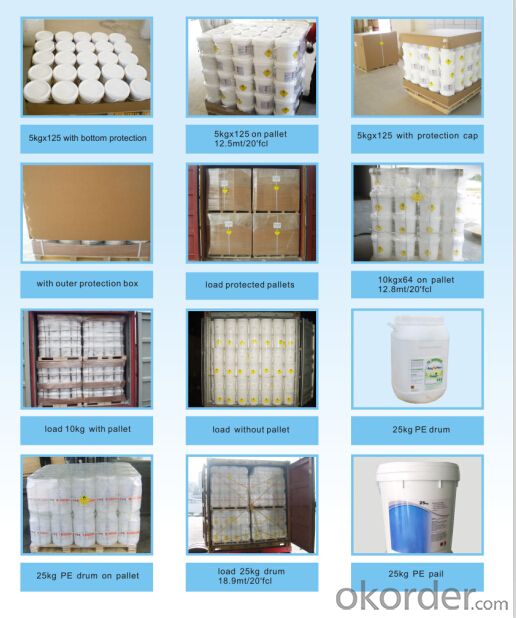

Package:

50KG PLASTIC DRUMS/ FIBER DRUMS.

25KG PLASTIC DRUMS/FIBER DRUMS.

1000KG BIG BAGS.

Or any other packages suggest by customers.

Application of SDIC in water treatment

1)It can be used for swimming pool and drinking water treatment, clean the industrial circulating water.

2)It can be used as preventive disinfection of house, hotel, hospital and public place; used on the environmental sterilization of raising fish.

3)It can be used to bleach the textile, to prevent wool from shrinkage, to prevent paper by decay and act as rubber chlorination.

Delivery Port

Tianjin Port

Payment terms :

T/T,L/C at sight

Storage :

Shall be sealed and stored in the dry and ventilated place to prevent from rain ,high temperature and strong sunlight .

Sample management

Free sample to be offered before place an order.

- Q:Explain how catalysts help to reduce costs in industrial processes !?Thanks

- they reduce the activation energy of a specific chemical reaction, which in turn reduces the temperature at which a reaction will occur at any significant rate (and therefore fuel costs) while generally making the reaction occur faster. In general, if you can catalyze a reaction, you can get away with using less robust equipment because you don't need as much energy.

- Q:What is the microcosmic principle of the catalytic reaction in the chemical reaction?

- The catalyst reduces the activation rate of the reactants by increasing the reactant density of the reaction conditions and making the chemical reaction easier.

- Q:Is palladium predominantly a catalyst in chemistry?

- Palladium in the chemical mainly to do the catalyst; palladium and ruthenium, iridium, silver, gold, copper and other alloy, can improve the palladium resistivity, hardness and strength, used in the manufacture of precision resistors, jewelry and so on.

- Q:a) A catalyst such as chlorophyll must be present for some reactions to take place.b) A catalyst such as chlorophyll is not one of the products of a chemical reaction.c) A catalyst such as chlorophyll is not a substance that is used or changed in a chemical reaction.

- Perky, I doubt that it would be B because everything could be said to be the result of a chemical reaction. I think the answer is C because you could paraphrase it to say; chlorophyll is a substance that does not participate in any chemical reactions, which is of course, not true.

- Q:If possible can anyone give me information on the active site, substrates, products, and the energy of activation as part of the answer?Responses greatly appreciated! Thankss! 10pts to best answer!

- To make it simple unlike the dude above me...enzymes (biological catalysts) lower the activation energy, which speeds up the reaction. EVERY reaction needs a little boost of energy--the activation energy--and enzymes lower that.

- Q:What kind of chemical substances can seriously damage the ozone layer, as a catalyst or reactants can be?

- Freon decomposition of free radicals. The destruction of our ozone is mainly caused by him. Chlorine free radicals are also available.

- Q:Now, i am studying for my biology exam in 3 weeks time...i stumbled upon catalase, and then checked my book its catalyst...now im confused...is there a different among these 2 terms? i think..catalyst is the when a substance brings up or about a chemical reaction without using itself up and then catalase breaks down the toxic by-product of metabolism, hydrogen peroxide, into water and oxygen.Or am i wrong?please explain what is catalyst and catalase in biology or are they the same, just differently?

- an enzyme that decomposes hydrogen peroxide into oxygen and water.a substance that causes or accelerates a chemical reaction without itself being affected. To put thing simply, a catalyst is any substance that speeds up a chemical reaction. These can be natural or manmade. Catalase is actually a specific type of naturally-occuring catalyst, an enzyme in cells that decomposes hydrogen peroxide (Which is extremely toxic to life!) into harmless components. Catalase enzymes are highly concentrated in the aptly named cell organelles known as peroxisomes. Just remember- if the word ends in -ase, it's a type of enzyme! :) Hope this information helps!

- Q:Chemical reactions in the presence of impurities will cause catalyst poisoning, how to understand this sentence

- This is in the chemical balance, but also alone

- Q:What suitable catalysts can I use for the reaction between Hydrochloric acid and zinc metal?

- catalysts are substances that alter the rate of a reaction.a suitable catalyst would be finely divided platinum.

- Q:My chemistry teacher wont tell me because it's in the higher course. And i'm not waiting a whole year to find out. And also, google is being a gimp about it. So thanks a lot if you know, I only have basic chemistry knowledge btw, lumen'ss terms if you can.

- Catalysts facilitate the reaction. They might work in several ways. Here is an example: Catalysts generally react with one or more reactants to form intermediates that subsequently give the final reaction product, in the process regenerating the catalyst. The following is a typical reaction scheme, where C represents the catalyst, X and Y are reactants, and Z is the product of the reaction of X and Y: X + C → XC (1) Y + XC → XYC (2) XYC → CZ (3) CZ → C + Z (4) Although the catalyst is consumed by reaction 1, it is subsequently produced by reaction 4, so for the overall reaction: X + Y → Z They might also just increase the surface area, thus speeding up the reaction. Example: Coke looses its fizz over time if left with the cork unscrewed. This is because the HCO3 is released as CO2. If you drop a menthos into the coke, it explodes with CO2, because the methos is full of tiny dents in the surface (thus giving it a massive surface area). (i blatantly copied the first example from the wiki)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SDIC Chlorine Powder Disinfectant Dichloroisocyanurate Sodium

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 1800 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches