Schedule 40 Seamless Carbon Steel Pipe X42 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.73 - 59.54 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Fluid Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Galvanized,vanish covering, black painting, galvenized ect. |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Length: | 5-12m as per customer's requirements |

| SCH: | SCH10~160, STD, XS & XXS | Payment Terms: | L/C T/T | Supply Ability: | 5000 Ton/Tons per Week |

| Product: | pipe prices | Grade: | 10#,20#,45#,A106(B,C),A53(A,B),12Cr1MoV,12Cr1MoVG,12Cr2Mo,13CrMo44,13CrMo45,15CrMo,15CrMoG,St52,St52.4,10#-45#,A53-A369,Cr-Mo alloy,ST35-ST52 | Standard: | API 5CT,API 5L,ASTM A106-2006,ASTM A53-2007,DIN 17175,GB 3087-1999,GB 5130,GB 6479-2000,GB 9948-2006,GB/T 17396-1998,GB/T 5312-1999,GB/T 8162-1999,GB/T 8163-1999,API,ASTM,DIN,GB |

Packaging & Delivery

| Packaging Detail: | By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers. |

| Delivery Detail: | within 5-15 days |

Specifications

1.pipe prices

2.Supply Ability:5000 Tons per Week

3.Payment Terms:L/C T/T

High quality Carbon steel pipe, Best pipe prices

1) Application: Overheat pipe for low and mediumpressure boiler,boiling water pipe, locomotive smoke pipe(big and small),Carry gas ,water or oil in the industries of petroleum and natural gas etc

2) Materials: 10#, 20#, 45#, 15CrMo, 12Cr1MoV, 13CrMo44, 12Cr2Mo, 13CrMo45, 12Cr1MoVG, 15CrMoG, API J55, API K55, API N80, API L80, API P110

3)Pipe according to standard: GB 3087-1999, GB/T 8163-1999, GB/T 8162-1999, GB 9948-2006, GB/T 17396-1998, GB/T 5312-1999, GB 6479-2000, GB 5130, DIN 17175, API 5CT, API 5L .

4)Packing: By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers.

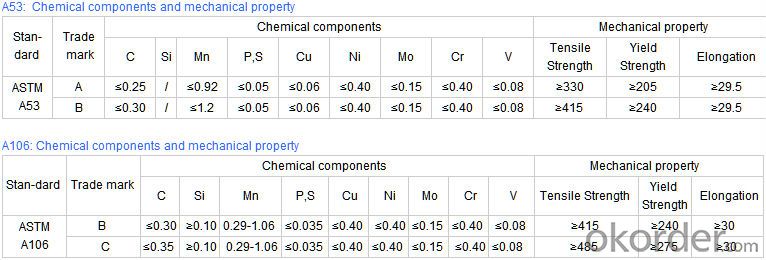

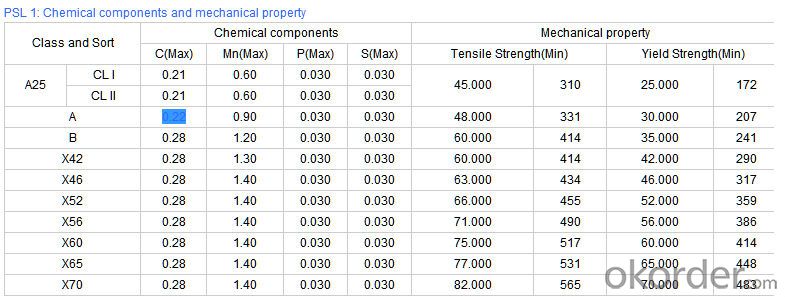

Technical Parameters of Seamless Steel Pipe

- Q:Can steel pipes be used for conveying slurries or abrasive materials?

- Indeed, the utilization of steel pipes proves effective in the conveyance of slurries or abrasive substances. Renowned for their robustness and endurance, steel pipes are aptly suited for the management of demanding tasks. They exhibit resistance against wear, corrosion, and impact, rendering them exceptionally suitable for transporting abrasive materials or slurries laden with solids or particles. Furthermore, steel pipes possess the ability to endure high pressure and retain their structural integrity, thereby guaranteeing the secure and efficient transportation of slurries or abrasive substances.

- Q:What connections are there for concrete filled steel tubular column foundations?

- Strengthening ring joint is a more common in the construction of steel pipe concrete column construction, it is to beam column connection through the upper and lower plate reinforcing ring bending force transmission way is through two to strengthen the uniform arrangement between the rings radial ribs and rib structure to connect with the ring the pipe wall at the top of the plate, so as to transfer the shear stress, so as to strengthen the thickness and improve the quality of connection engineering advantage. In the process of engineering construction, according to the construction principle of longitudinal reinforcement of Deng Qiang to control, so that the smaller width of not less than the replacement of the width of the connecting plate 70%, also need to be given due attention in the form of node selection

- Q:What are the different types of steel pipe reducers?

- Various industrial applications commonly use different types of steel pipe reducers. These reducers facilitate the connection between pipes of varying sizes, ensuring a smooth transition in fluid or gas flow. The following are some of the most frequently encountered types: 1. Concentric Reducers: These reducers possess a symmetrical design with a centerline that aligns with both the larger and smaller pipes' centerlines. They facilitate a gradual reduction in pipe size, ensuring a seamless material flow. 2. Eccentric Reducers: In contrast to concentric reducers, eccentric reducers have an offset centerline. This design is beneficial in preventing the accumulation of air or gases in the piping system. The eccentric reducer directs any gas or air towards a vent or drain point. 3. Welded Reducers: These reducers are created through the welding of two pipes of different sizes. They are frequently used in situations that require a permanent connection. 4. Seamless Reducers: Seamless reducers are manufactured without any welded joints. They are crafted from a single piece of steel, enhancing their strength and durability. Seamless reducers are often preferred in applications where leak-proof connections are crucial, such as high-pressure or high-temperature environments. 5. Threaded Reducers: These reducers have male and female threads on both ends, allowing for easy installation and removal. They are commonly used in low-pressure applications and are a cost-effective option for systems that require frequent disassembly. 6. Flanged Reducers: Flanged reducers possess flanges on both ends, which are bolted together to create a secure seal. They are frequently used in piping systems that require convenient access for maintenance or inspection. Each type of steel pipe reducer offers its own unique advantages and is selected based on the specific requirements of the application. Factors such as the transported fluid or gas type, pressure and temperature conditions, and the need for easy installation or maintenance should be considered when choosing the appropriate reducer for a particular system.

- Q:What are the main components of a steel pipe?

- The main components of a steel pipe are the base metal, which is typically made of carbon steel or alloy steel, and the protective coating, which is applied to prevent corrosion and enhance durability. Additionally, joints or connections are important components that allow for the seamless connection of multiple pipes.

- Q:How do you prevent corrosion in steel pipes?

- One effective way to prevent corrosion in steel pipes is by applying a protective coating, such as paint or epoxy, to the surface of the pipes. This barrier creates a physical barrier between the pipe and the surrounding environment, preventing moisture and corrosive agents from coming into direct contact with the steel. Additionally, regular inspection and maintenance of the pipes, including cleaning and repairing any damaged coating, can help identify and address potential issues before they lead to corrosion.

- Q:Can steel pipes be used for steam distribution?

- Yes, steel pipes can be used for steam distribution. Steel pipes are commonly used in steam distribution systems due to their high strength, durability, and resistance to high temperatures and pressure. They can effectively handle the transportation of steam in various industries such as power generation, chemical processing, and heating systems.

- Q:What are the common grades of steel used in pipes?

- The common grades of steel used in pipes include ASTM A53, ASTM A106, and API 5L.

- Q:ASME seamless tube how to express, what is the form, I did not find on the ASME, thank God!

- Welded and seamless pipe standards are ASME B31.10, no go, if you want to force a seamless tube, the request can be seamless for seamless meaning.In addition to that, the cost and difficulty of manufacturing welded pipe is higher than that of seamless tube.

- Q:How are steel pipes resistant to corrosion?

- Steel pipes are resistant to corrosion due to the protective layer formed on their surface. This layer, also known as a passive film, is created through the presence of chromium in the steel. It acts as a barrier, preventing oxygen and moisture from reaching the underlying metal, thus inhibiting the corrosion process. Additionally, steel pipes can also be coated with anti-corrosive materials like zinc or epoxy, providing an extra layer of protection against rust and other corrosive elements.

- Q:What is the average cost of steel pipes?

- The average cost of steel pipes can vary significantly depending on factors such as size, grade, and quantity needed. Therefore, it is difficult to provide a specific average cost without more information.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Schedule 40 Seamless Carbon Steel Pipe X42 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords