Schedule 40 Seamless Carbon Steel Pipe API P110 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.73 - 59.54 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Fluid Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Galvanized,vanish covering, black painting, galvenized ect. |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Length: | 5-12m as per customer's requirements |

| SCH: | SCH10~160, STD, XS & XXS | Payment Terms: | L/C T/T | Supply Ability: | 5000 Ton/Tons per Week |

| Product: | pipe prices | Grade: | 10#,20#,45#,A106(B,C),A53(A,B),12Cr1MoV,12Cr1MoVG,12Cr2Mo,13CrMo44,13CrMo45,15CrMo,15CrMoG,St52,St52.4,10#-45#,A53-A369,Cr-Mo alloy,ST35-ST52 | Standard: | API 5CT,API 5L,ASTM A106-2006,ASTM A53-2007,DIN 17175,GB 3087-1999,GB 5130,GB 6479-2000,GB 9948-2006,GB/T 17396-1998,GB/T 5312-1999,GB/T 8162-1999,GB/T 8163-1999,API,ASTM,DIN,GB |

Packaging & Delivery

| Packaging Detail: | By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers. |

| Delivery Detail: | within 5-15 days |

Specifications

1.pipe prices

2.Supply Ability:5000 Tons per Week

3.Payment Terms:L/C T/T

High quality Carbon steel pipe, Best pipe prices

1) Application: Overheat pipe for low and mediumpressure boiler,boiling water pipe, locomotive smoke pipe(big and small),Carry gas ,water or oil in the industries of petroleum and natural gas etc

2) Materials: 10#, 20#, 45#, 15CrMo, 12Cr1MoV, 13CrMo44, 12Cr2Mo, 13CrMo45, 12Cr1MoVG, 15CrMoG, API J55, API K55, API N80, API L80, API P110

3)Pipe according to standard: GB 3087-1999, GB/T 8163-1999, GB/T 8162-1999, GB 9948-2006, GB/T 17396-1998, GB/T 5312-1999, GB 6479-2000, GB 5130, DIN 17175, API 5CT, API 5L .

4)Packing: By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers.

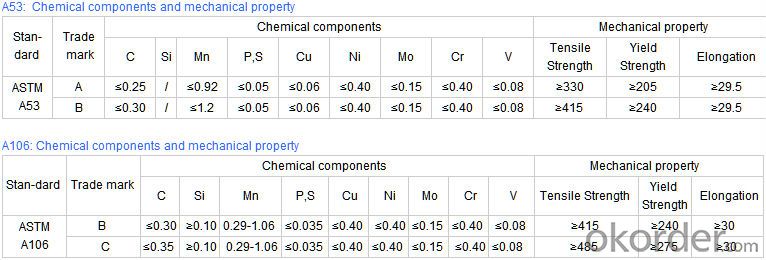

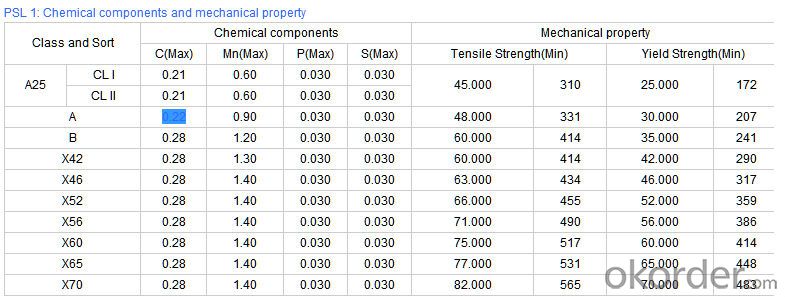

Technical Parameters of Seamless Steel Pipe

- Q:How are steel pipes used in stadium construction?

- Steel pipes are commonly used in stadium construction for various purposes such as structural support, plumbing systems, and the installation of lighting and audio equipment. They provide strength, durability, and versatility, making them ideal for ensuring the overall stability and functionality of the stadium.

- Q:How do you measure the diameter of a steel pipe?

- To measure the diameter of a steel pipe, you can use a caliper or a measuring tape. Place the caliper jaws or measuring tape around the widest part of the pipe, ensuring it is perpendicular to the pipe's axis. Take the reading displayed on the caliper or measure the distance between the two points on the measuring tape. This measurement will provide you with the diameter of the steel pipe.

- Q:What is the difference between steel pipe and fiberglass pipe?

- Steel pipe and fiberglass pipe differ in terms of their material composition, flexibility, resistance to corrosion, and cost. Steel pipe is made of an alloy of iron and carbon, known for its strength and durability, making it a popular choice for plumbing, construction, and industrial projects. In contrast, fiberglass pipe is composed of glass fibers embedded in a resin matrix, resulting in a lightweight and corrosion-resistant material suitable for applications requiring chemical resistance. Another contrasting factor between steel pipe and fiberglass pipe is their level of flexibility. Steel pipe is rigid and stiff, while fiberglass pipe offers greater flexibility, allowing it to bend and conform to different shapes and contours. This flexibility makes fiberglass pipe easier to install in tight spaces or areas with complex geometries. Corrosion resistance is another significant difference between the two materials. Steel pipe is susceptible to corrosion, particularly in environments with high moisture or chemical exposure. To counteract this, steel pipes are often coated or lined with corrosion-resistant materials. In contrast, fiberglass pipe is inherently resistant to corrosion due to its construction, making it a preferred choice for applications in saltwater environments or chemical processing plants. Cost is yet another factor that sets steel pipe and fiberglass pipe apart. Generally, steel pipe is more affordable than fiberglass pipe, especially for smaller diameter pipes. However, as the diameter and pressure rating increase, the cost of steel pipe can exceed that of fiberglass pipe. Additionally, fiberglass pipe requires less maintenance and has a longer lifespan, which can offset the initial cost difference over time. In conclusion, the differences between steel pipe and fiberglass pipe can be summarized in terms of their material composition, flexibility, corrosion resistance, and cost. The choice between these two types of pipes depends on various project requirements, including the application, environment, budget, and expected lifespan.

- Q:What are the advantages of using steel pipes in the manufacturing of furniture?

- There are several advantages of using steel pipes in the manufacturing of furniture. Firstly, steel pipes provide durability and strength, ensuring that the furniture is sturdy and long-lasting. Secondly, steel pipes have a sleek and modern appearance, adding a contemporary touch to the furniture design. Additionally, steel pipes are resistant to corrosion, making them suitable for both indoor and outdoor furniture. Lastly, steel pipes are versatile and can be easily shaped and welded, allowing for customization and flexibility in furniture design.

- Q:Can steel pipes be used for wastewater treatment?

- Indeed, wastewater treatment can make use of steel pipes. The construction of wastewater treatment plants and systems frequently incorporates steel pipes owing to their robustness, resilience, and resistance to corrosion. Their exceptional suitability lies in their capacity to handle the transportation and distribution of wastewater, given their ability to withstand substantial pressure and temperature fluctuations. Moreover, steel pipes have the potential to be coated or lined with materials that offer supplementary protection against corrosion and chemical reactions with the wastewater. Nonetheless, it is crucial to ensure the adequate upkeep, inspection, and replacement of steel pipes when required, to avert potential leaks or failures that could jeopardize the wastewater treatment process.

- Q:Are the welded and galvanized tubes the same weight?

- The difference is that because zinc has weight, even if the difference is very small, there are also differences,Galvanized pipe weight is basically the same about 1.06 of the welded tube, of course, you can artificially ignored.

- Q:How are steel pipes protected against electrolytic corrosion?

- Steel pipes are protected against electrolytic corrosion through various methods such as applying protective coatings, using sacrificial anodes, implementing cathodic protection systems, or utilizing corrosion inhibitors. These measures help to prevent the flow of electric current and the subsequent corrosion caused by electrolysis, ensuring the longevity and integrity of the steel pipes.

- Q:How are steel pipes classified according to their wall thickness?

- Steel pipes are classified according to their wall thickness into various categories such as standard, extra strong, and double extra strong.

- Q:What are the different types of joints used in steel pipes?

- There are several types of joints commonly used in steel pipes, including threaded, welded, flanged, and grooved joints.

- Q:Why should the weak electricity be pre buried with galvanized steel pipe?

- Galvanized steel pipe mainly because of anti-interference and electrical connectivity, to prevent other strong magnetic strong signal to interfere with weak signal, while in the electrical connection, galvanized steel pipe can be directly connected to the bridge.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Schedule 40 Seamless Carbon Steel Pipe API P110 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords