Schedule 40 Seamless Carbon Steel Pipe A335P92 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.73 - 59.54 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Fluid Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Galvanized,vanish covering, black painting, galvenized ect. |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Length: | 5-12m as per customer's requirements |

| SCH: | SCH10~160, STD, XS & XXS | Payment Terms: | L/C T/T | Supply Ability: | 5000 Ton/Tons per Week |

| Product: | pipe prices | Grade: | 10#,20#,45#,A106(B,C),A53(A,B),12Cr1MoV,12Cr1MoVG,12Cr2Mo,13CrMo44,13CrMo45,15CrMo,15CrMoG,St52,St52.4,10#-45#,A53-A369,Cr-Mo alloy,ST35-ST52 | Standard: | API 5CT,API 5L,ASTM A106-2006,ASTM A53-2007,DIN 17175,GB 3087-1999,GB 5130,GB 6479-2000,GB 9948-2006,GB/T 17396-1998,GB/T 5312-1999,GB/T 8162-1999,GB/T 8163-1999,API,ASTM,DIN,GB |

Packaging & Delivery

| Packaging Detail: | By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers. |

| Delivery Detail: | within 5-15 days |

Specifications

1.pipe prices

2.Supply Ability:5000 Tons per Week

3.Payment Terms:L/C T/T

High quality Carbon steel pipe, Best pipe prices

1) Application: Overheat pipe for low and mediumpressure boiler,boiling water pipe, locomotive smoke pipe(big and small),Carry gas ,water or oil in the industries of petroleum and natural gas etc

2) Materials: 10#, 20#, 45#, 15CrMo, 12Cr1MoV, 13CrMo44, 12Cr2Mo, 13CrMo45, 12Cr1MoVG, 15CrMoG, API J55, API K55, API N80, API L80, API P110

3)Pipe according to standard: GB 3087-1999, GB/T 8163-1999, GB/T 8162-1999, GB 9948-2006, GB/T 17396-1998, GB/T 5312-1999, GB 6479-2000, GB 5130, DIN 17175, API 5CT, API 5L .

4)Packing: By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers.

Technical Parameters of Seamless Steel Pipe

- Q:Seamless steel pipe 8162 and 8163 what is the difference?

- GB 8162 is the structure of the tube, there is no need for flaw detection, the use of mechanical processing, stents;

- Q:How do you transport and store steel pipes?

- Careful planning and adherence to safety guidelines are essential when it comes to the transportation and storage of steel pipes. The following steps outline the necessary procedures: 1. Select the appropriate mode of transportation: Depending on the quantity and weight of the steel pipes, you have the option to transport them by truck, train, or ship. Evaluate the distance, logistics, and cost-effectiveness of each alternative before making a decision. 2. Package and secure the steel pipes: Proper packaging is crucial to prevent damage during transit. Bundle the pipes together using steel strapping or banding, ensuring a tight and secure fastening to prevent any shifting or movement during transportation. 3. Utilize suitable lifting equipment: When loading and unloading the pipes, make use of appropriate lifting equipment such as cranes, forklifts, or hoists. Ensure that the equipment is capable of safely handling the weight and length of the pipes. 4. Protect against moisture and corrosion: Steel pipes are vulnerable to moisture and corrosion, which can weaken their structural integrity. Apply a protective coating or wrap the pipes with waterproof materials before transportation. Additionally, consider using moisture-absorbing desiccants or placing the pipes on pallets to keep them elevated off the ground. 5. Plan for secure storage: If storing the steel pipes for an extended period, select a dry and secure location. Ensure that the storage area is well-ventilated and shielded from direct exposure to sunlight, rain, or extreme temperatures. Utilize racks or pallets to keep the pipes off the ground and prevent contact with moisture. 6. Conduct thorough inspections for damage: Prior to transportation and after storage, perform comprehensive inspections to identify any damage or signs of corrosion. This proactive approach will enable prompt resolution of any issues and ensure the integrity of the steel pipes. It is important to adhere to local regulations and safety guidelines specific to your region when transporting and storing steel pipes. By following these steps, you can guarantee the safe and efficient transportation and storage of steel pipes while minimizing the risk of damage and preserving their quality.

- Q:Can steel pipes be used for wastewater treatment facilities?

- Yes, steel pipes can be used for wastewater treatment facilities. Steel pipes are known for their durability, corrosion resistance, and high strength, which makes them suitable for handling various types of wastewater and harsh chemicals. Additionally, steel pipes can be easily welded, allowing for flexibility in design and installation.

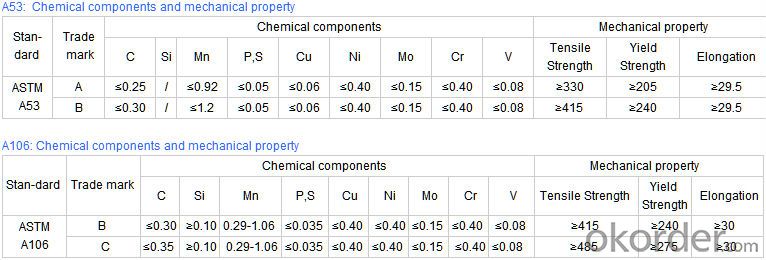

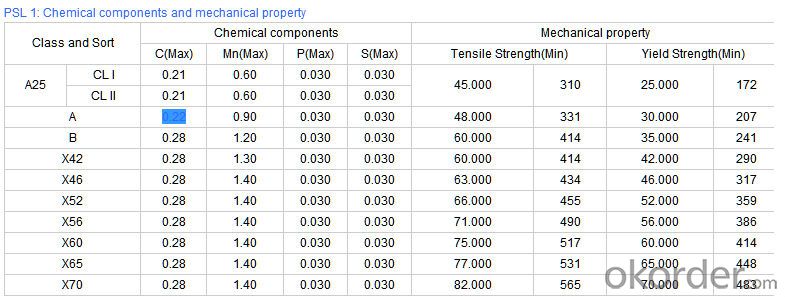

- Q:What is the difference between API 5L and ASTM A53 steel pipes?

- API 5L and ASTM A53 are widely utilized carbon steel pipe standards with similar purposes but notable distinctions. 1. In terms of scope, API 5L pertains to seamless and welded pipes for transporting oil, gas, water, and other fluids. It encompasses plain-end, threaded-end, and belled-end pipe types. Conversely, ASTM A53 is a standard specification for seamless and welded black and hot-dipped galvanized steel pipes utilized in mechanical and pressure applications. 2. The manufacturing processes differ, as API 5L pipes undergo hot-rolling, while ASTM A53 pipes undergo either hot-rolling or cold-drawing. This variance affects the chemical composition and mechanical properties of the pipes. 3. Generally, API 5L pipes have a higher carbon content compared to ASTM A53 pipes. This discrepancy arises from the intended use of API 5L pipes for conveying oil, gas, and water, necessitating greater strength and durability. On the other hand, ASTM A53 pipes cater to mechanical and pressure applications, where lower carbon content is deemed appropriate. 4. API 5L pipes exhibit higher minimum yield strength and tensile strength than ASTM A53 pipes. This outcome stems from the increased carbon content and more stringent manufacturing process employed for API 5L pipes. Conversely, ASTM A53 pipes possess lower yield and tensile strength requirements, rendering them more suitable for general-purpose applications. 5. API 5L pipes offer various coating options, including black varnish, 3PE, FBE, among others, depending on the specific application requirements. In contrast, ASTM A53 pipes are typically hot-dipped galvanized to enhance corrosion resistance. In conclusion, API 5L and ASTM A53 steel pipes differ in scope, manufacturing processes, chemical compositions, mechanical properties, and coating options. The appropriate choice of pipe hinges upon specific application requirements, such as the nature of the conveyed fluid, operating conditions, and desired strength and durability.

- Q:Are steel pipes recyclable?

- Yes, steel pipes are recyclable.

- Q:Can steel pipes be used for telecommunications cables?

- No, steel pipes cannot be used for telecommunications cables. Telecommunications cables typically require materials with high electrical conductivity and insulation properties, such as copper or fiber optics. Steel pipes are not suitable for transmitting signals and would interfere with the transmission of data.

- Q:Can steel pipes be used for transporting chemicals?

- Yes, steel pipes can be used for transporting chemicals. Steel pipes are known for their strength, durability, and resistance to corrosion, making them suitable for handling various chemicals. Additionally, steel pipes can withstand high pressure and temperature conditions, ensuring safe transportation of chemicals.

- Q:How do steel pipes compare to other materials, such as PVC or copper?

- Steel pipes have several advantages over other materials such as PVC or copper. Firstly, steel pipes are incredibly durable and strong, making them suitable for heavy-duty applications and high-pressure environments. Additionally, steel pipes have a longer lifespan compared to PVC or copper, as they are less prone to cracking, corrosion, or degradation. Steel pipes also provide better fire resistance and are more resistant to extreme temperatures. However, steel pipes can be more expensive and require professional installation due to their weight and rigidity. PVC pipes, on the other hand, are lightweight, affordable, and easy to install, but they may not be as durable or suitable for certain applications. Copper pipes offer excellent corrosion resistance and are commonly used for water supply systems, but they can be more expensive and require skilled labor to install. Ultimately, the choice between steel, PVC, or copper pipes depends on the specific requirements of the project and the desired balance of cost, durability, and performance.

- Q:What are the lengths of scaffold steel tubes?

- Scaffold tubes are our name for materials used to build scaffolding, because most scaffolding uses tubular bamboo or steel tubing. Bamboo and other bamboo is for a long time in the use of the scaffolding tube, but due to lack of safety and durability, now only in rural and urban area construction is lagging behind some of the home building small building has been used. The modernization construction, the most commonly used type of scaffolding pipe is steel pipe, the scaffolding should not only meet the demand of workers, but also to meet the characteristics of scaffolding firm and durable, so tough hard steel is the best choice. The selected steel pipe generally requires smooth surface, no cracks, no bending, no rust, and meet the relevant national standards.

- Q:How are steel pipes used in the automotive manufacturing industry?

- Steel pipes are commonly used in the automotive manufacturing industry for various purposes such as exhaust systems, fuel lines, and structural components. They provide durability, strength, and resistance to high temperatures, making them ideal for these applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Schedule 40 Seamless Carbon Steel Pipe A335P92 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords