Scaffolding Machine Formwork Scaffolding Hook CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Scaffolding Machine Formwork Scaffolding Hook CNBM

Plastic Formwork Concrete Formwork Scaffolding Manufacturer Scaffolding Spanners with New Design

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks.

The advantages of plastic formworks:

Scaffolding Machine Formwork Scaffolding Hook CNBM

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

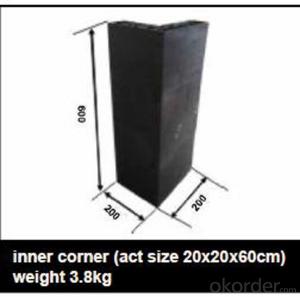

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Scaffolding Machine Formwork Scaffolding Hook CNBM

Scaffolding Machine Formwork Scaffolding Hook CNBM

Scaffolding Machine Formwork Scaffolding Hook CNBM

Scaffolding Machine Formwork Scaffolding Hook CNBM

- Q:How does steel frame formwork accommodate for different concrete surface finishes?

- Steel frame formwork is a versatile system that can easily accommodate different concrete surface finishes. One of the main advantages of using steel frame formwork is its flexibility in creating various surface textures and finishes. To achieve different concrete surface finishes, steel frame formwork can be customized by using different types of form liners, textures, or surface treatments. Form liners are commonly used to create patterns or textures on the concrete surface. These liners are made from various materials, such as rubber, plastic, or fiberglass, and can be easily attached to the steel formwork. For a smooth finish, the steel formwork can be lined with smooth form liners, allowing the concrete to set with a flat and uniform surface. On the other hand, if a textured or patterned finish is desired, form liners with specific designs can be used. These liners can create different textures, such as brick patterns, wood grains, or even unique designs. In addition to form liners, other surface treatments can be applied to the steel formwork to enhance the concrete surface finish. These treatments may include applying release agents, chemical retarders, or pigments to achieve specific effects. Release agents help in preventing the concrete from sticking to the formwork, allowing for easy removal and a smooth finish. Chemical retarders can be used to slow down the setting time of the concrete, which is beneficial for achieving exposed aggregate or textured finishes. Pigments can also be added to the concrete mix to introduce color and create visually appealing surfaces. Overall, steel frame formwork provides a flexible platform for achieving various concrete surface finishes. By using different form liners, textures, and surface treatments, the steel formwork can be customized to meet the desired finish requirements. This versatility makes steel frame formwork an ideal choice for projects where different surface finishes are desired.

- Q:Can steel frame formwork be used for parking structures?

- Yes, steel frame formwork can be used for parking structures. Steel frame formwork offers high strength and durability, making it suitable for constructing large and robust parking structures. It provides the necessary support and stability during the concrete pouring process, resulting in a strong and reliable parking structure.

- Q:How does steel frame formwork handle the placement of concrete in structures with complex geometries or irregular shapes?

- Steel frame formwork is a versatile and reliable solution for handling the placement of concrete in structures with complex geometries or irregular shapes. Its adaptable nature allows for easy customization and adjustment, ensuring a precise fit to the unique requirements of each project. The steel frame provides the necessary strength and stability to support the weight of the concrete, enabling efficient and secure pouring. Additionally, the formwork system allows for quick assembly and disassembly, facilitating the construction process in these challenging scenarios.

- Q:How does steel frame formwork handle different types of concrete mixes and aggregates?

- Steel frame formwork is a versatile and robust system that can handle different types of concrete mixes and aggregates effectively. Its strong and rigid structure ensures the containment of various types of concrete mixes, including lightweight, normal weight, and heavyweight concrete. Additionally, the adjustable height and width of the steel frames allow for accommodating different aggregate sizes, whether it is fine or coarse aggregates. The stability and durability of steel frame formwork make it suitable for handling the varying characteristics of concrete mixes and aggregates, ensuring a reliable and consistent construction process.

- Q:Can steel frame formwork be used for both straight and sloped surfaces?

- Yes, steel frame formwork can be used for both straight and sloped surfaces. The steel frames can be easily adjusted and reinforced to accommodate the desired angle or curve of the surface, making it suitable for various construction projects.

- Q:What are the key considerations for selecting the appropriate steel frame formwork system for projects with limited construction budgets?

- When selecting a steel frame formwork system for projects with limited construction budgets, there are several key considerations to keep in mind. Firstly, it is important to evaluate the cost-effectiveness of the system. This includes assessing the initial cost of the formwork, as well as any additional expenses such as transportation, installation, and maintenance. Secondly, the durability and lifespan of the system should be considered to ensure it can withstand the demands of the project without requiring frequent repairs or replacements. Additionally, the versatility and adaptability of the formwork system should be taken into account, as it should be able to accommodate various types of structures and design requirements. Lastly, the availability and accessibility of the system should be considered, as it should be easily procurable within the limited budget and readily available for use. By considering these factors, one can select an appropriate steel frame formwork system that meets both the budgetary constraints and construction needs of the project.

- Q:Can steel frame formwork be used for both horizontal and vertical concrete elements?

- Yes, steel frame formwork can be used for both horizontal and vertical concrete elements. It is a versatile and robust system that can be easily adjusted and reused for various construction projects.

- Q:What are the different types of concrete finishes that can be achieved with steel frame formwork?

- There are several types of concrete finishes that can be achieved with steel frame formwork, including smooth finishes, textured finishes, exposed aggregate finishes, stamped finishes, and stained finishes.

- Q:Can steel frame formwork be used for both indoor and outdoor construction projects?

- Steel frame formwork can be utilized in both indoor and outdoor construction ventures. Its reputation for durability, strength, and versatility enables it to be suitable for diverse construction applications, regardless of project location. Whether employed in the construction of building foundations, walls, columns, or slabs, steel frame formwork can endure the elements, delivering dependable support and stability. Furthermore, its adaptability allows for easy adjustments to accommodate various shapes and sizes, making it an excellent option for both indoor and outdoor construction projects.

- Q:Can steel frame formwork be used for both single-sided and double-sided concrete pouring?

- Yes, steel frame formwork can be used for both single-sided and double-sided concrete pouring. The steel frame provides strong support and stability, allowing it to withstand the pressure of the concrete from either one or both sides during pouring. This versatility makes steel frame formwork a suitable choice for various construction projects requiring different pouring methods.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Scaffolding Machine Formwork Scaffolding Hook CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products