Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

Plastic Formwork Concrete Formwork Scaffolding Manufacturer Scaffolding Spanners with New Design

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

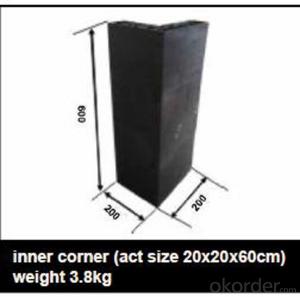

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

- Q:Can steel frame formwork be used in projects with limited space for storage and staging?

- Yes, steel frame formwork can be used in projects with limited space for storage and staging. Steel frame formwork is known for its compact design and lightweight construction, making it suitable for projects with limited storage space. Additionally, steel frame formwork can be easily stacked and stored, maximizing the available space without compromising on efficiency and productivity.

- Q:How does steel frame formwork help in reducing material waste?

- Steel frame formwork helps in reducing material waste in several ways. Firstly, steel frame formwork is highly durable and can be reused multiple times. Unlike traditional wooden formwork, which often needs to be discarded after a few uses, steel formwork can withstand many construction cycles without losing its structural integrity. This means that less material is needed for each construction project, as the same formwork can be used repeatedly. Secondly, steel frame formwork is adjustable and customizable. This allows for precise shaping and sizing of concrete structures, minimizing the need for excessive material usage. With wooden formwork, it is often necessary to cut and shape the wood to fit the desired structure, resulting in wastage of excess material. Steel formwork, on the other hand, can be easily adjusted and reused for different projects, reducing the amount of material that goes to waste. Additionally, steel formwork provides a smooth and even surface finish, reducing the need for additional material to be used for surface treatments. This eliminates the need for plastering or smoothing out uneven surfaces, which would otherwise require additional materials such as plaster or cement. By providing a high-quality finish directly from the formwork, steel frame formwork minimizes the amount of material waste in the form of surface treatments. Overall, steel frame formwork helps in reducing material waste by being reusable, adjustable, and providing a high-quality finish. These characteristics contribute to a more efficient and sustainable construction process, ultimately reducing the overall environmental impact of construction projects.

- Q:What is the role of steel frame formwork in achieving a smooth concrete finish?

- The steel frame formwork plays a crucial role in achieving a smooth concrete finish by providing a stable and rigid structure that holds the concrete in place during the pouring and curing process. Its precision engineering ensures that the formwork remains in position, preventing any movement or deformation while the concrete sets. This stability allows for precise concrete placement and reduces the risk of surface imperfections. Additionally, the smooth surface of the steel formwork prevents any texture transfer onto the concrete, resulting in a clean and polished finish.

- Q:Can steel frame formwork be used for architectural concrete finishes?

- Yes, steel frame formwork can be used for architectural concrete finishes. Steel frame formwork offers a high level of precision and accuracy in shaping and molding the concrete, making it suitable for achieving architectural concrete finishes. The steel frames provide stability and support to the formwork, ensuring that the desired shape and design of the concrete is maintained throughout the pouring and curing process. Additionally, steel frame formwork can be easily adjusted and modified to accommodate different architectural designs and complex shapes. The smooth and seamless surface of the steel formwork also contributes to achieving a high-quality architectural concrete finish.

- Q:Can steel frame formwork be used for both vertical and horizontal concrete elements?

- Yes, steel frame formwork can be used for both vertical and horizontal concrete elements. Steel frame formwork is a versatile and durable system that can be easily assembled and adjusted to accommodate various shapes and sizes of concrete structures. The steel frames provide sufficient strength and stability to support the weight and pressure exerted by the wet concrete during pouring and curing processes. This makes it suitable for constructing walls, columns, beams, slabs, and other types of concrete elements, both vertically and horizontally. The steel frame formwork system allows for quick and efficient construction, ensuring high-quality results and reducing construction time and costs.

- Q:PKPM can be used to calculate the deflection of steel frame beam

- Can consider the effect of the plate on the beam of the beam to calculate the deflection of the beam, the deflection calculation is based on the actual reinforcement, in the PKPM should be the actual reinforcement input checking, can not use PKPM directly generated deflection.

- Q:How does steel frame formwork contribute to the overall safety of a construction site?

- Steel frame formwork contributes to the overall safety of a construction site by providing a sturdy and durable structure for concrete pouring. Its robustness ensures that the formwork can withstand the weight and pressure of wet concrete, minimizing the risk of collapse or structural failure. Additionally, the steel frame's rigidity helps maintain the accuracy and stability of the formwork system, reducing the chances of any accidents or errors during construction.

- Q:The following is a two storey steel frame to be done above the door of the frame of 9 meters high, with the PKPM model is the use of door type rigid frame, with interlayer, or the lower frame, the upper

- If you use PKPM modeling, you can use the steel frame module calculation, it is best not to separate calculation.

- Q:How does steel frame formwork contribute to the overall strength and stability of a concrete structure?

- Various ways exist in which steel frame formwork is instrumental in enhancing the overall strength and stability of a concrete structure. Firstly, the steel frame functions as a rigid and robust framework, offering support to the concrete during the pouring and curing process. This containment and shaping of the concrete guarantee the prevention of any sagging, bulging, or deformation that could potentially weaken the structure. In addition, the steel frame formwork allows for precise and accurate placement of the concrete, ensuring consistency and uniformity throughout the structure. This eradicates any potential weak points or irregularities that might compromise the overall strength. Furthermore, the steel frame formwork exhibits excellent resistance against external forces like wind, seismic activity, or heavy loads. Its high tensile strength and durability enable it to withstand these forces, thus enhancing the overall stability of the concrete structure. Moreover, the steel frame formwork creates a controlled environment that facilitates the proper curing of the concrete. This controlled environment minimizes the risk of shrinkage, cracking, or moisture-related issues that could considerably weaken the structure over time. The steel frame formwork's ability to allow for a consistent and controlled curing process contributes to the long-term strength and durability of the concrete structure. In summary, steel frame formwork's contribution to the overall strength and stability of a concrete structure lies in its provision of a rigid support system, ensuring accuracy and uniformity in placement, resisting external forces, and facilitating proper curing. Its durability and robustness make it an indispensable component in the construction process, ultimately enhancing the structural integrity and longevity of the concrete structure.

- Q:What are the different types of connections used in steel frame formwork systems?

- There are two main types of connections used in steel frame formwork systems: bolted connections and welded connections. Bolted connections involve the use of nuts and bolts to secure the different components together, providing flexibility in assembly and disassembly. Welded connections, on the other hand, involve fusing the structural elements using heat, resulting in a permanent and strong connection. Both types of connections have their advantages and disadvantages depending on the specific requirements of the construction project.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords