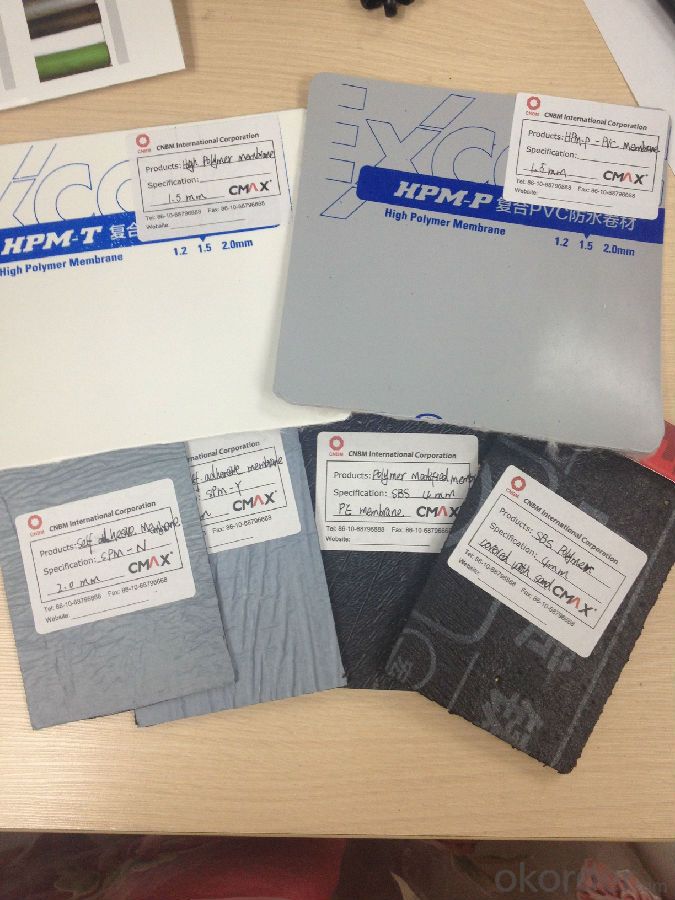

SBS Elastomeric Polymer Bitumen Waterproof Roofing Membrane Tpae

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick DetailsType:

Waterproof Membrane, Waterproof membrane Place of Origin: China (Mainland)

Surface film: PE, SAND, SCHIST,aluminum Thickness: 2.0mm~5.0mm Length: 10.0m

Width: 1.0m Usage: waterproofing for roof, understand,etc

Packaging & DeliveryPackaging Details: 10 sq.m./roll export package or as requirment

Delivery Detail: 15 days after receipt of deposit.

Specifications3mm SBS modified bitumen waterproof membrane

1) 2--5mm

2) Base:PY/G

3) Surface:PE / S / M / Al

Application:

1. Make sure the base surface smooth, clean and dry(Moisture<9%), then paint the delicated agent on the base surface. start application till it is dry.< span="">

2. Application Method:

Heating the bottom surface of membrane and the roof deck surface by flam spray gun or other suitable appliances till the asphalt start to melt(not flowing), then spread. Using roller to compact the membrane so that it can firmly adhere to the base surface. The overlap on the long side should be 100mm and the short side should be 150mm.

3. After application, a careful inspection is required. Make sure there is no air bubble, no fold, no falling away etc to guarantee the waterproof life.

Package

the membrane is launched into the market in rolls 1m wide and 10m long.

Storage Conditions and Service life

Rolls must be vertically stored in roofed-over spaces. If the rolls have to be stored outdoors for a long period of time, then they must be covered with a protective layer in order to protect them against the sunlight. If the rolls are to be stowed without pallets, they they are not stacked one on top of another. In palletised stowage, two rows may be stacked one on top of the other.

Attentions for Construction

·

SBS / APP asphalt waterproof membrane, bituminous waterproof membrane

1. Membranes should be stored under dry and ventilated conditions.

2. Different types of membranes must be piled separately.

3. Under usual condition, storage period is one year since production date.

4. Membrane roll should be put vertically during transportation. It should be kept away

from sunshine and rainwater.

Installation Sketch point

Clean the substrate using broom or high pressure dusty cleaner.

Apply primer

Heat the membrane bottom using a high temperature flame gun.

Push forward while the primer and membrane oil melted

Use a roller to push hard the membrane surface to ensure it stick firmly

Why choose us?

1,Honest supplier to the worldwide buyers

2,Factory, direct supplier, competitive price

3,Know how to control the costing with 30 years experience

4,Warm and friendly service and guide

5,China National Standard GB/18242-2008

6,3 shifts workers for 24hrs production, high capacity

7,Small and big orders are welcome from the worldwide

8, 24 hours service for you

FAQ

1,Q:Are you a factory or trading company?

A:We are a factory

2,Q:Where is your factory located?How can i visit there?

A:Our factory is located in Zhengzhou City,Henan Province,China,about 2 hours plane from Shanghai,Guangzhou ect.We can pick you up at the airport.All our clients,from home or abroad,are warmly welcome to visit us!

3,Q:How can i get some samples?

A:We are honored to offer you Free samples.

4:Q:How does your factory do regarding quality control?

A:Quality is priority.King Waterproof Material people always attach great importance to quality controlling from the every beginning to the very end.Our factory has gain ISO9001:2008,ISO4001:2000 ,CEC And LANxess Testing

- Q:Can a waterproofing membrane be used for a balcony deck?

- Yes, a waterproofing membrane can be used for a balcony deck. In fact, it is often a recommended solution for protecting balcony decks from water damage. A waterproofing membrane is designed to create a barrier that prevents water from seeping into the underlying structure, thereby safeguarding the deck from moisture-related issues such as rot, mold, and deterioration. It is typically applied as a liquid or sheet material over the surface of the balcony deck, forming a seamless and impenetrable layer. This membrane acts as a protective shield, ensuring that any water that comes into contact with the deck is repelled and directed away. By using a waterproofing membrane, you can effectively extend the lifespan of your balcony deck and maintain its structural integrity for years to come.

- Q:Can a waterproofing membrane be applied in wet conditions?

- No, a waterproofing membrane cannot be applied in wet conditions. In order for the membrane to properly adhere to the surface and create an effective barrier against water, the surface must be dry and free from any moisture. Applying a waterproofing membrane in wet conditions can result in poor adhesion, which can compromise its effectiveness and lead to water leakage. It is essential to ensure that the surface is completely dry before applying the membrane to achieve the desired waterproofing results.

- Q:How does a waterproofing membrane handle moisture from the ground?

- To effectively manage moisture from the ground, a waterproofing membrane is designed to create a barrier that stops water infiltration. It is typically constructed using impermeable materials like rubber, bitumen, or modified asphalt. When correctly implemented, the membrane forms a continuous, watertight layer that prevents water from seeping through the foundation or walls. Typically, the membrane is placed on the exterior side of a building's foundation, where it serves as a protective shield against groundwater. It is applied directly onto the concrete or masonry surface, forming a seamless and durable waterproofing layer. To ensure its long-term durability, the membrane is then covered with a protective layer, such as soil or backfill. In addition to being impermeable, a waterproofing membrane also incorporates features that enable it to handle moisture effectively. For example, it may include built-in channels or dimples that facilitate the drainage of water away from the foundation, preventing the accumulation of hydrostatic pressure. Some membranes even possess self-healing properties, allowing them to seal minor punctures or cracks that may develop over time. Overall, a properly installed waterproofing membrane serves as a dependable barrier against ground moisture. It safeguards the structure from water damage, prevents the growth of mold and mildew, and maintains a dry and healthy indoor environment. However, it is crucial to ensure correct installation by adhering to the manufacturer's guidelines and seeking assistance from experienced professionals to guarantee its effectiveness.

- Q:How does a waterproofing membrane handle construction vibrations?

- A waterproofing membrane is designed to withstand construction vibrations by providing a flexible and durable barrier against potential damage caused by these vibrations. Its composition and installation techniques ensure that it can absorb and dissipate the energy generated by construction activities, minimizing the risk of any cracks or leaks that could compromise its waterproofing effectiveness.

- Q:Can a waterproofing membrane be used on nickel surfaces?

- Indeed, nickel surfaces can benefit from the use of a waterproofing membrane. These membranes are frequently employed in construction and building ventures to safeguard surfaces against water damage and moisture infiltration. They serve as a barrier, preventing water from seeping through the surface and causing harm. Like any other metal surfaces, nickel surfaces can be vulnerable to corrosion and water-induced damage. By applying a waterproofing membrane, the nickel surface can be effectively shielded from water and moisture, thereby prolonging its lifespan and preserving its integrity. However, it is crucial to guarantee that the chosen waterproofing membrane is suitable for use on nickel surfaces. Different membranes may have distinct compatibility requirements, which is why it is advisable to consult the manufacturer or a professional for guidance on proper application and compatibility.

- Q:Can a waterproofing membrane be used for a shopping mall?

- Indeed, a waterproofing membrane is suitable for the application in a shopping mall. Due to its multiple levels and extensive surface area, a shopping mall is prone to water infiltration from various sources such as rain, plumbing leaks, and others. By incorporating a waterproofing membrane, one can effectively safeguard the structure and its contents against water damage. Typically, this membrane is installed on the exterior walls, roofs, and foundation of the shopping mall to establish a barrier against moisture penetration. Acting as a protective layer, it effectively prevents water from seeping into the building, thereby minimizing the risk of structural deterioration, mold growth, and related problems. Moreover, a properly installed waterproofing membrane can also augment energy efficiency by reducing heat loss and preventing water-induced deterioration of insulation materials. Thus, employing a waterproofing membrane is a prudent decision to ensure the long-lasting durability and functionality of a shopping mall.

- Q:Can a waterproofing membrane be applied to wood surfaces?

- Wood surfaces can indeed be protected with a waterproofing membrane. There are various options available in the market, including liquid or sheet membranes that are specially designed for wood. These membranes are typically made from materials like rubber, asphalt, or polyurethane, which form a barrier against water and prevent moisture from seeping into the wood. The application of the waterproofing membrane varies depending on the product, and can involve brushing, rolling, or spraying. By applying a waterproofing membrane to wood surfaces, the wood's lifespan can be extended, rotting and warping can be prevented, and water damage can be avoided. However, it is crucial to properly prepare the surface and follow the manufacturer's instructions for application in order to achieve optimal results.

- Q:Can a waterproofing membrane be used in kitchens?

- Yes, a waterproofing membrane can be used in kitchens. In fact, it is highly recommended to use waterproofing membranes in areas prone to moisture and water exposure, such as kitchens. These membranes are designed to create a barrier against water and prevent it from seeping into the underlying structure, protecting it from damage. They are commonly used on floors, walls, and even countertops to ensure a watertight seal and prevent water damage, mold growth, and other issues. Additionally, waterproofing membranes can also help with soundproofing and provide added durability and longevity to the kitchen surfaces.

- Q:Can a waterproofing membrane be used on precast concrete surfaces?

- Yes, a waterproofing membrane can be used on precast concrete surfaces. It helps to prevent water penetration and protect the concrete from moisture damage.

- Q:Can a waterproofing membrane be used on concrete slabs or foundations?

- Yes, a waterproofing membrane can be used on concrete slabs or foundations. It serves as a protective barrier against water penetration, preventing moisture-related issues such as leaks, mold, and structural damage. The membrane is typically applied to the exterior surface of the concrete to create a waterproof seal.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SBS Elastomeric Polymer Bitumen Waterproof Roofing Membrane Tpae

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords