Sandwichpanel Prefabricated House | Camp House Sandwichpanele

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Eps Sandwich Panel Water Proof Sandwich Panel

Light weight

High intensity Sound proof Easy installation

Eps Sandwich Panel Water Proof Sandwich Panel

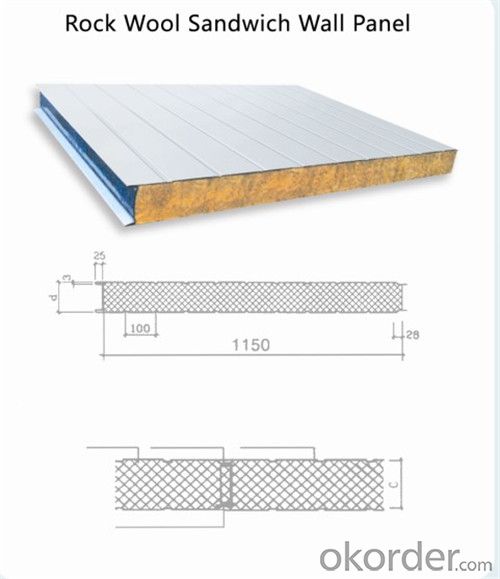

The usual sandwich panels include rock wool Sandwich panel, EPS sandwich panels, PU Sandwich Panel, glass fiber sandwich pannels. The up & down surface of this panel is Galvanized & Prepainted steel sheets, core material is rock rood, EPS, PU, and glass fiber. It is formed by heating, foaming & laminating. It is the best material for temperature keeping and sound insulation. It is widely used as the wall or roof for cold storage, industrial workshop, public building etc.

Specifications

(1)Core Material: Rock Wool, EPS, PU; Surface Materials: Galvanized Steel sheets or Prepainted Steel sheets.

(2)Wall Thickness: 40, 50, 60, 80,100,120,150,180,200,250mm

(3)Max. Width: 1200mm

(4)Length: according to client's demands, engineering requirements and shipment conditions

(5) Application: for ceiling & wall, partition wall

(6) Widely used in common steel structure and storey adding projects,e.g. adding storey to small steel structure industrid factory building worehouse,suburbon temporary office,residentid quarters,school,hospital,etc.

Characteristics

1) With a light weight, a giraffe fitting and random incise characteristic, the fitting is much simpler, and it can advance the benefit and save the time limit for a project

2) Color coated sandwich panel's surface material and heat preservation material are non-burn or hard-burn materials, entirely satisfy the fireproofing criterion request

3) Manifold disquisition and oversea used approving more than 40 years. By especial coated dispose, the color coated steel panel's guaranty is 10-15 years, and the panel's life express 35 years by painting the antisepsis material after each 10 years

4) Pressing steel panel with the clear line, and many colors for choice, and suit with any different building style materials, achieving the satisfying effects.

5) In common use heat preservation materials are rock-wool, polystyrene,

polyurethane, all with lower thermal conductivity and favorable heat preservation and heat insulation effects

6) Sound insulation intension can be 40-50dB, it is the most effective sound insulation material

7) Pressing steel panel can be arbitrariness incise, it can satisty the especially design demands

8) Use the high strength steel panel for the base metal (contradict open and pull intension 5,600kg/cm2), adding the most advanced design and roll pressing moulding, it gets the best structure character

9) Improves speediness and springiness designs according to clients' requirements.

- Q:How to calculate the allowable slenderness ratio of steel structures under compression?

- The slenderness ratio is in the majority of cases for the component, and the formula coffee has given. As for the concept, it is easy to see from the formula that the slenderness ratio is the ratio of the length of the member to its corresponding radius of gyration.

- Q:Housing cost of civil steel structure

- Want to do high-rise residential steel structure also needs a long time in the domestic steel structure at present is industrial plant or self light steel villa type, or a certain first high-rise steel structure of high-rise residential can really do very little the price factor is part of the reason the other hand is the global scope for steel structure high-rise residential fire safety, maintenance cost and technology has not been able to reach. At the same time, the domestic people's knowledge of the steel structure residential is still relatively small, and the popularization of steel structure housing also needs a process.

- Q:What are the different types of steel bridges?

- There are several types of steel bridges, including truss bridges, beam bridges, arch bridges, suspension bridges, and cable-stayed bridges.

- Q:What is the role of steel in historical and heritage buildings?

- The role of steel in historical and heritage buildings is significant and multifaceted. Steel has played a crucial role in the construction and preservation of these structures, providing strength, durability, and versatility. Historically, steel became a prominent material in the late 19th and early 20th centuries with the advent of the Industrial Revolution. Its introduction revolutionized the architecture and engineering industries, allowing for the construction of taller and more expansive buildings. The use of steel frames and beams provided a higher level of structural support, enabling architects to create grand structures with larger open spaces and intricate designs. In heritage buildings, steel has often been utilized during restoration and rehabilitation projects. Many historical buildings suffer from structural deterioration over time, and steel is often used to reinforce weakened or damaged sections. Its high tensile strength and ability to withstand heavy loads make it an ideal material for reinforcing weakened foundations, walls, or floors. Moreover, steel is also used in the restoration of ornate architectural elements. Historical buildings often feature intricate ironwork, such as balconies, railings, or decorative facades. When these elements become rusted or damaged, steel can be used to replicate or replace them, ensuring the preservation of the building's original aesthetic. Additionally, steel plays a crucial role in the adaptive reuse of historical and heritage buildings. Many old structures are repurposed for new functions, such as converting a factory into a museum or a warehouse into residential lofts. Steel's versatility allows architects and engineers to modify the building's interior layout while retaining its historical exterior. Steel beams can be added or modified to accommodate new spaces or support additional floors, providing the necessary flexibility for modern usage. Lastly, steel is a sustainable choice for historical and heritage buildings. Its recyclability and durability make it an environmentally friendly material. By using steel in restoration or adaptive reuse projects, we can reduce the need for new materials and minimize waste, contributing to the preservation of these invaluable structures for future generations. In conclusion, steel plays a vital role in historical and heritage buildings, both in their initial construction and ongoing preservation. Its strength, durability, versatility, and sustainability make it the material of choice for reinforcing structures, restoring ornate elements, adapting buildings for new uses, and ensuring the longevity of these iconic landmarks.

- Q:How are steel structures designed for different access systems?

- Steel structures can be designed to accommodate different access systems by considering factors such as load capacities, safety regulations, and functionality requirements. The design process involves determining the type of access system required, such as staircases, elevators, or cranes, and considering their specific dimensions and weight capacities. Structural engineers also consider the placement and integration of these access systems within the overall design of the steel structure to ensure optimal functionality and ease of use.

- Q:What are the considerations for designing steel structures for sustainable construction?

- When designing steel structures for sustainable construction, several considerations must be taken into account. Firstly, the selection of materials plays a crucial role. Opting for recycled or low-carbon steel can significantly reduce the environmental impact. Additionally, considering the life cycle analysis of the structure helps to determine its overall sustainability by assessing its embodied energy and carbon footprint. Designing for flexibility and adaptability ensures that the structure can accommodate future changes without the need for extensive modifications or demolition. Lastly, incorporating energy-efficient measures such as insulation, efficient lighting, and renewable energy sources further enhances the sustainability of steel structures.

- Q:What are the different types of steel sections or profiles used in construction?

- Some common types of steel sections or profiles used in construction include I-beams, H-beams, C-channels, angles, and tubes. These sections are designed to provide structural support and are often used in the construction of buildings, bridges, and other infrastructure projects.

- Q:What are the factors to consider when designing steel structures for healthcare facilities?

- When designing steel structures for healthcare facilities, several factors need to be considered. These include the specific requirements and regulations of healthcare facilities, such as infection control, patient safety, and accessibility. The structural integrity of the building, including load-bearing capacity and resistance to natural disasters, is crucial. Additionally, considerations must be made for the functionality and flexibility of the space to accommodate medical equipment, technology, and future expansions. Energy efficiency, sustainability, and the integration of advanced building systems are also important factors to ensure a safe and efficient healthcare environment.

- Q:How are steel structures used in the construction of parking structures?

- Steel structures are commonly used in the construction of parking structures due to their strength, durability, and cost-effectiveness. Steel beams and columns are used to provide structural support, allowing for wide open spaces and maximizing parking capacity. Additionally, steel's flexibility allows for easy customization and adaptability to meet specific design requirements. Its fire resistance and ability to withstand harsh weather conditions make it a reliable choice for constructing parking structures that need to stand the test of time.

- Q:How are steel structures used in automotive manufacturing plants?

- Steel structures are used extensively in automotive manufacturing plants to provide a strong and durable framework for various operations. They are used for constructing the plant's main building, assembly lines, and storage facilities. Steel structures offer the necessary strength and stability to support heavy machinery, equipment, and vehicles, ensuring a safe working environment for employees. Additionally, steel can be easily customized and modified, allowing for efficient expansion or reconfiguration of the plant as needed. Its corrosion resistance and fireproof properties also contribute to the overall safety and longevity of automotive manufacturing plants.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Sandwichpanel Prefabricated House | Camp House Sandwichpanele

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords