Saltworks Geomembrane with Good Quality and Low Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description:

Our product was proved as good mechanic performance, high tearing resistance, strong deformation adaptability, puncture, aging,

ultra-violet radiation, high and low temperature resistance, good waterproof, drainage, anti-seepage , complete width and thickness

specifications, low cost and simple construction.

1.used in landfill caps

2. base liner applications under roads, railways,

3.They are also used for waterproofing of buildings and other similar structures.

2.Product Characteristic:

1),Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial,

hospital solid waste, etc.) .

2),Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart,

slope protection, etc.).

3), Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining,

etc.).

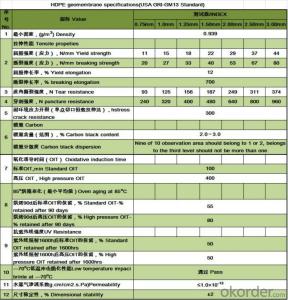

3.Product Specifications:

1.Thickness : 0.1mm---3mm,

2.Length: 50 m -100 m ; width: 4 m -8 m ( according to customer needs )

3.Elongation at break 600%

4.Material: HDPE.

5.Color: Black or as required

4.Reference Picture

- Q:What are the benefits of using geomembranes in stormwater ponds?

- There are several benefits of using geomembranes in stormwater ponds. Firstly, geomembranes act as a protective barrier, preventing the infiltration of stormwater into the surrounding soil, thus reducing the risk of groundwater contamination. Secondly, they help to control and manage stormwater runoff, allowing for better retention and storage of water during heavy rainfall events. Additionally, geomembranes can help to reduce the growth of algae and other unwanted vegetation in stormwater ponds, improving water quality and aesthetics. Lastly, these membranes provide stability to the pond structure and prevent erosion, ensuring the longevity and durability of the stormwater management system.

- Q:What is geotextile

- The geotextile is also known as the geotextile, which is made of synthetic fibers that are made of permeable synthetic material by needle punching or weaving. Finished product is cloth form, the general width is 4-6 meters and the length is 50-100 meters. The geotextile is divided into woven geotextile and non-woven geofabric. The geotextile has excellent filtration, drainage, isolation, reinforcement, seepage prevention and protection, and has the characteristics of light weight, high tensile strength, good permeability, high temperature resistance, freezing resistance, aging resistance and corrosion resistance.

- Q:What are the typical widths of geomembranes?

- The typical widths of geomembranes vary depending on the specific application and project requirements. However, common widths range from 4 to 10 meters (13 to 33 feet).

- Q:How many kinds does the films of glass door?

- High transparent ceramic materials: glass film processed into nano particles deposited into; that adhere to the highest transmittance and the maximum can absorb solar energy. This type of film reflectivity is very low, the insulation is attributed to the high rate, high power in the world of commodity. Called IR type heat reflective film. Usage: glass film metal function layer after interlayer or magnetron sputtering plating skills made, with the intention to reach many reflected solar radiation heat and light. Heat reflective glass film has outstanding shading function and heat insulation function, make indoor light soft and comfortable. The one-way perspective: the glass film metal function layer through the interlayer or magnetron sputtering techniques the plating is made, with the highest reflection of solar radiation and visible light function. Facing the light side with mirror characteristics, the opposite perspective. This can appearance reflective layer mirror effect and color of the building Decoration effect of good, namely, one-way perspective type with reflection translucency and pleochroism. Perspective: that adhere to the high transparency, but also cut off from the inevitable heat from the sun, is modern buildings throughout the use of glass membrane type. Widely used in commercial and residential buildings.

- Q:Can geomembranes be used in fishpond lining?

- Yes, geomembranes can be used in fishpond lining. They are often used as liners in aquaculture systems to prevent leakage and contamination of water.

- Q:What is the construction technology of geotechnical engineering?

- (1) Geological surveying and mapping. (2) Exploration and sampling. (3) In-situ test and laboratory test. (4) On-site inspection and monitoring. Engineering geological mapping is the basis of geotechnical engineering investigation and is usually carried out in the early stages of the investigation. The essence of this approach is to use geological and engineering geological theory to observe and describe the geological phenomenon, analyze its nature and rules, and thereby infer the geological condition of the subsurface providing evidence for other investigation methods like exploration and testing. In sites that have complex topography and geological conditions, engineering geological mapping must be carried out. However, for sites that is of flat terrain, simple geological conditions and relatively small space, engineering geological mapping survey can be replaced by investigation. Engineering geological mapping is the most economical and effective way to know the engineering geological conditions. High-quality mapping work can be fairly accurately infer the subsurface geological condition and effectively guide other investigation methods.

- Q:Can geomembranes be used in hydraulic structures?

- Yes, geomembranes can be used in hydraulic structures. They are often used as liners or barriers in various hydraulic applications such as canals, reservoirs, dams, and waste containment systems. Geomembranes provide effective waterproofing, erosion control, and containment of liquids or gases, making them a suitable choice for hydraulic structures.

- Q:Geomembrane sn2/ what does pe represent for?

- Two cloths one membrane,

- Q:Can geomembranes be used in decorative swimming pools and water features?

- Yes, geomembranes can be used in decorative swimming pools and water features. Geomembranes are impermeable liners that can effectively prevent water leakage and provide a reliable barrier. They are commonly used in various applications, including decorative pools and water features, to ensure water containment and prevent seepage into the surrounding soil.

- Q:How to remove the mobile phone film?

- the film on the mobile phone can be directly removed, the above glue can be cleared: 1, the first step is using drawing eraser to wipe screen so you can remove most of the offset print; 2, the second step is to use a small amount of toothpaste, it is better to choose a good one, which is the kind will not wear CD box as advertised, a little bit evenly on the surface of the screen, but it is better not to seep into the screen edge seam. Then add a little water to slowly rub on the screen, you can remove stubborn dirt. 3,Second step, you can also use the wet paper towel gently wipe the residual dirt. 4, the third step, use a damp cloth to wipe clean the screen, a light screen appears.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Saltworks Geomembrane with Good Quality and Low Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords