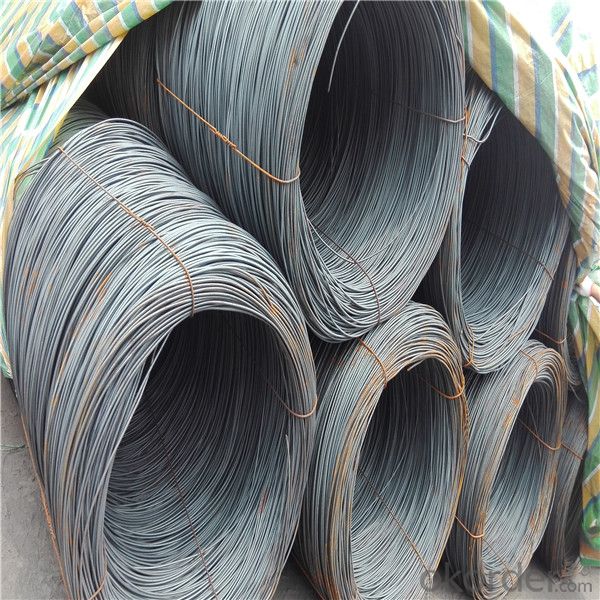

SAE1008 Steel wire rod 5.5mm-14mm low carbon

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 17645 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Produced from billets at the rolling mill, wire rod is the basis of all steel wire, rope and fencing products.

The most important characteristic in determining wire rod’s end use is its drawability. Common low carbon

wire rod is used for nails, small shaped products, barbed wires, various wire nettings, steel chains, and

other applications. High Carbon wire rod uses include steel tire cords for automobiles, conveyor belts, and

pressure hoses. Other applications include bolts, nuts, and machine parts, as well as compression, tension

and torsion springs.

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale,

easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Product Description :

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material/steel grade | Q195-Q235,SAE1006B,SAE1006CR, SAE1008B, SAE1008CR, SAE1010B, SAE1018B, or according to customers requirements |

Wire Gauge | 5.5-12mm |

Coil weight | 1.8-2.1mts |

MOQ | 25MT |

Delivery Time | 15-30 days after receipt of L/C or deposit by T/T |

Packing | In coil and load in container, if large quantity, by bulk vessel; Can be packed as customers' special requirements |

Payment terms | 1).100% irrevocable L/C at sight. 2).30% T/T prepaid and the balance against the copy of B/L. 3).30% T/T prepaid and the balance against L/C |

Application | widely used in machinery parts, manufacturing industry, electronics industry, metal tools and others |

Application :

It generally used in braiding the hose for bathing product and machinery. With it

good flexibility, resistant to high temperature and resistant to corrosion, it

used widely in many industries.

Packing :

Hot-rolled wire rod is held in a unit with at least four steel straps in the

transverse direction and transported and stored without further packaging.

Before

the steel strapping is applied, the wire rod must be sufficiently compressed.

The strapping is fixed in the transverse direction with a single circumferential

strap so that the strapping does not slip and cause the coil to come apart.

Our service:

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing

consistently high standards of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in

customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with

shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can

achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our

key markets. To maintain our position as market leader we must continue to add

value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the

professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3

-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q:What are the challenges faced by the steel wire rod manufacturers?

- Some challenges faced by steel wire rod manufacturers include fluctuating raw material prices, intense competition in the market, evolving customer demands, and compliance with environmental regulations. Additionally, maintaining product quality, ensuring efficient production processes, and managing supply chain logistics are also significant challenges for these manufacturers.

- Q:How is steel wire rod used in the manufacturing of cable wires?

- Steel wire rod is used in the manufacturing of cable wires as it serves as the primary raw material for their production. The steel wire rod is first drawn through a series of dies to reduce its diameter and increase its strength. This process is called wire drawing. The resulting wire is then coated with a layer of insulation material to protect it from damage and ensure proper electrical conductivity. The insulated steel wire is further twisted or braided with other wires to form the cable, which is used for various applications such as electrical wiring, telecommunications, and power transmission.

- Q:How is steel wire rod used in the manufacturing of wire harnesses?

- Steel wire rod is used in the manufacturing of wire harnesses as it serves as the primary material for the conductive wires within the harness. The wire rod is first drawn into the desired diameter and then processed further to remove any impurities or surface defects. These high-quality wires are then twisted, braided, or insulated to create the necessary configuration for the wire harness, providing the required strength, flexibility, and electrical conductivity. Overall, steel wire rod plays a crucial role in ensuring the durability and performance of wire harnesses in various industries, including automotive, aerospace, and electronics.

- Q:What are the main factors affecting the market investments of steel wire rod?

- The main factors affecting the market investments of steel wire rod include global demand and supply dynamics, raw material prices, competition from alternative materials, economic and political factors, technological advancements, and regulatory policies.

- Q:What are the common applications of low alloy and oil tempered steel wire rod?

- Low alloy and oil tempered steel wire rod have a wide range of common applications in various industries. One common application is in the manufacturing of automotive components. Low alloy and oil tempered steel wire rod is used to make springs, such as suspension springs and valve springs, which are crucial for the proper functioning of vehicles. The high strength and durability of these steel wire rods make them ideal for withstanding the demanding conditions and heavy loads experienced by automobiles. Another common application is in the construction industry. Low alloy and oil tempered steel wire rod is used to make reinforcing bars (rebars), which are essential for reinforcing concrete structures like buildings, bridges, and highways. The strength and ductility of these steel wire rods ensure that the reinforced structures can withstand the stresses and pressures they are subjected to, providing stability and longevity. In addition, low alloy and oil tempered steel wire rod is also used in the manufacturing of various industrial equipment and machinery. These steel wire rods are commonly used to make wire ropes, which are used in cranes, elevators, and other lifting equipment. The high tensile strength and resistance to corrosion of these steel wire rods make them suitable for withstanding heavy loads and harsh environments. Furthermore, low alloy and oil tempered steel wire rod finds applications in the production of wire mesh, fencing, and other wire products. The strength and durability of these steel wire rods ensure that the wire products can withstand external forces and provide security or containment in various settings, such as construction sites, agricultural fields, and industrial facilities. Overall, the common applications of low alloy and oil tempered steel wire rod include automotive components, construction reinforcement, industrial equipment, and wire products. The unique properties of these steel wire rods, such as high strength, durability, and resistance to corrosion, make them versatile materials that contribute to the functionality and reliability of various products and structures.

- Q:What are the common industry standards for steel wire rod manufacturers?

- The common industry standards for steel wire rod manufacturers include adherence to internationally recognized quality management systems such as ISO 9001, compliance with national and international standards like ASTM, JIS, and EN, and meeting specific customer requirements regarding diameter, tensile strength, surface finish, and chemical composition. Additionally, manufacturers may also follow industry best practices for production processes, testing procedures, and packaging to ensure the consistent quality and performance of their steel wire rod products.

- Q:How are steel wire rods used in the manufacturing of fasteners?

- Steel wire rods are an essential component in the manufacturing of fasteners. Fasteners, such as bolts, screws, and nails, are used to join or secure two or more objects together. Steel wire rods serve as the raw material for fasteners, providing the necessary strength and durability. The manufacturing process begins with steel wire rods, which are usually made from carbon or alloy steel. These rods are typically produced through a hot rolling process, where the steel is heated and then passed through a series of rollers to achieve the desired shape and size. The resulting wire rods are then further processed to meet the specific requirements of fastener production. One of the primary uses of steel wire rods in fastener manufacturing is for the production of bolts and screws. The wire rods are typically cut into specific lengths and then undergo a series of operations, such as heading, threading, and heat treatment. Heading involves forming the head of the bolt or screw, while threading creates the ridges or grooves that allow them to be screwed into place. Heat treatment is often employed to enhance the strength and hardness of the fastener. Steel wire rods are also used in the production of nails. The rods are first drawn to the desired diameter and then cut into appropriate lengths. The ends of the wire are sharpened, and the nails are formed by a process called pointing. Pointing involves creating a sharp tip on one end of the wire, which allows the nail to penetrate materials easily. In addition to bolts, screws, and nails, steel wire rods are used in the manufacturing of other fasteners, such as rivets, cotter pins, and clips. These fasteners are essential in various industries, including construction, automotive, aerospace, and furniture. Overall, steel wire rods play a crucial role in the manufacturing of fasteners by providing the necessary strength, durability, and versatility required for joining and securing objects together. They serve as the foundation for the production of various fastener types, enabling the construction of strong and reliable structures.

- Q:How does the fatigue strength of steel wire rod vary with different heat treatment processes?

- The fatigue strength of steel wire rod can vary significantly depending on the methods of heat treatment employed. Heat treatment involves subjecting the steel wire rod to specific heating and cooling processes in order to change its microstructure and mechanical properties. One commonly used heat treatment process to improve the fatigue strength of steel wire rod is quenching and tempering. This process includes heating the wire rod to a high temperature and then rapidly cooling it (quenching) to achieve a hardened microstructure. This leads to an increase in the fatigue strength of the wire rod because the hardened structure provides better resistance against fatigue failure. The subsequent tempering process involves reheating the wire rod to a lower temperature and slowly cooling it, which helps to relieve internal stresses and improve the toughness of the wire rod while maintaining an optimum balance of strength and ductility. On the other hand, if the steel wire rod undergoes a heat treatment process at a lower temperature, such as annealing, the fatigue strength may be reduced. Annealing involves heating the wire rod to a specific temperature and allowing it to cool slowly, often in a controlled atmosphere. This process is used to soften the wire rod, relieve internal stresses, and improve its machinability and formability. However, the resulting softer microstructure may cause a decrease in fatigue strength compared to quenched and tempered wire rod. In conclusion, the fatigue strength of steel wire rod can be improved through heat treatment processes like quenching and tempering, which lead to a hardened microstructure. Conversely, heat treatment processes like annealing can decrease the fatigue strength by producing a softer microstructure. Therefore, the selection of heat treatment processes is crucial in determining the fatigue strength of steel wire rod.

- Q:How does the tensile strength of steel wire rod vary with different diameters?

- The tensile strength of steel wire rod can vary depending on its diameter. Generally, as the diameter of the wire rod increases, its tensile strength also tends to increase. This is because a larger diameter allows for more surface area, which helps the material resist deformation when under tension. In addition, a larger diameter wire rod usually contains more material, making the overall structure stronger. However, it is important to note that the relationship between diameter and tensile strength is not always straightforward. There comes a point where increasing the diameter of the wire rod may not have a significant impact on its tensile strength. This is because factors like the steel's grade, microstructure, and any treatments or heatings it undergoes can also affect its strength. Furthermore, factors other than diameter can influence the tensile strength of steel wire rod. These factors include the manufacturing process, as well as any subsequent treatments, such as drawing processes, heat treatments, and the presence of alloying elements. Therefore, when considering the tensile strength of steel wire rod with different diameters, it is crucial to consider all these factors in order to accurately determine the relationship between diameter and tensile strength.

- Q:What are the safety precautions to be taken while handling steel wire rod?

- When handling steel wire rods, it is important to take certain safety precautions to minimize risks. First and foremost, wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots is crucial to protect against potential injuries. Additionally, workers should be trained on proper lifting techniques and use mechanical aids, such as cranes or forklifts, if necessary, to avoid strain or accidents. It is important to ensure a clear and organized work area, free from any obstructions or tripping hazards. Regular inspections of the wire rods for any defects or damage should also be conducted to prevent accidents. Lastly, maintaining good communication and following established safety protocols can further enhance overall safety while handling steel wire rods.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SAE1008 Steel wire rod 5.5mm-14mm low carbon

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 17645 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords