S35C Forged Alloy Steel Round Bars with Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description:

1. Sizes: Diameter: 16mm-300mm; Length: 6m, 9m, 12m

2. Grade: 35#, SAE1035, S35C, C35

3. Invoicing on theoretical weight or actual weight as customer’s request

4. Shape: Round bar, solid bar of steel with circular section

5. Technique: Hot rolled, forged, cold rolled

Chemical Composition:

C | Si | Mn | P | S | Ni | Cr | Cu |

0.32-0.40 | 0.17-0.37 | 0.50-0.80 | ≤0.035 | ≤0.035 | ≤0.30 | ≤0.25 | ≤0.25 |

Packing and Delivery:

Packing in bundle with steel strips and shipped by break bulk vessel or container (depend on target market and different ports)

Delivery Detail: Approx.45 days

Usage and Applications:

1. Steel round bar is used in a large number of architectural and engineering structures. Or it can be used in construction of plants for the production of steel house frames, high-voltage transmission towers, bridges, vehicles, boilers, containers, ships, etc.

2. And we can use this kind of product on the performance of the mechanical parts if the demand is not very high.

3. Some especial material steel round bar can be used for main shaft of steamer, hummer shank, with big section and supper force.

Specification:

OD | Length | Material | Standard | Technique |

16-260mm | 6-12m or aques per request | 20# | GB ASTM DIN | Hot rolled |

16-350mm | 35# | |||

200-500mm | 35# | Forged | ||

20-250mm | 20Cr,40Cr,20-42CrMo | Hot rolled | ||

50-300mm | GCr15 |

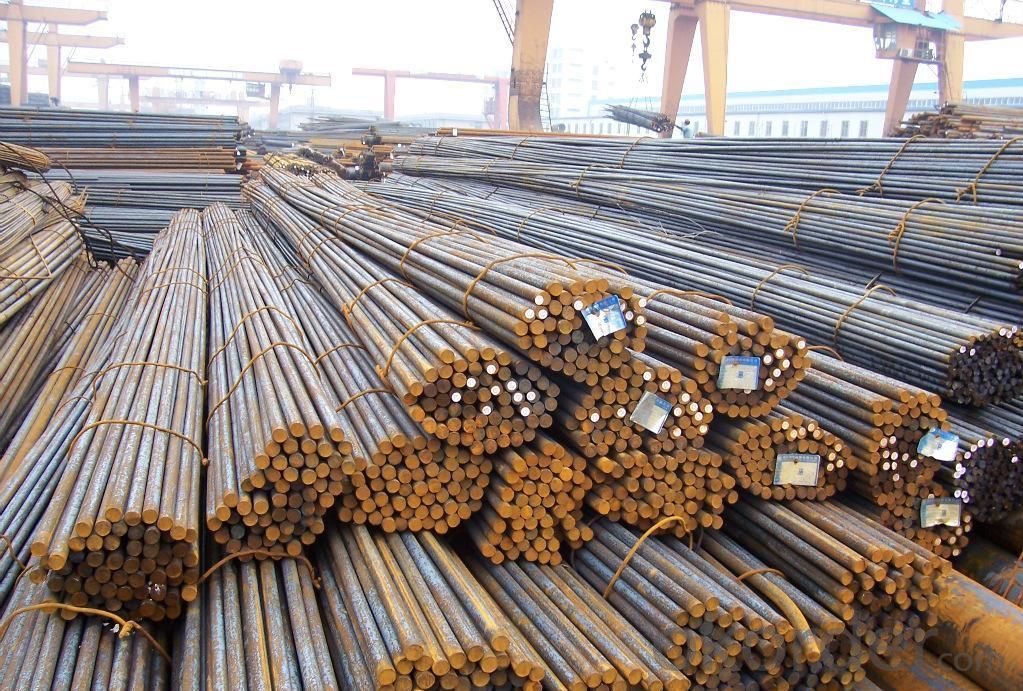

Main product pictures:

- Q:What are the requirements for special steel used in textile machinery?

- The requirements for special steel used in textile machinery include high strength and durability, excellent corrosion resistance, good wear resistance, and the ability to withstand high temperatures and pressures. Additionally, the steel should have good machinability and be able to maintain dimensional stability under various operating conditions.

- Q:What are the main characteristics of wear-resistant castings?

- Wear-resistant castings are specifically designed to withstand the harsh conditions of wear and abrasion. The main characteristics of these castings include: 1. Hardness: Wear-resistant castings are made from materials that have a high hardness rating. This allows them to resist deformation, surface damage, and wear caused by friction and impact. 2. Toughness: In addition to being hard, wear-resistant castings also possess high toughness. This means they can absorb energy without fracturing or breaking, ensuring their longevity and durability in challenging environments. 3. Corrosion resistance: Wear-resistant castings are often resistant to corrosion and oxidation, which helps to extend their lifespan and maintain their performance even in corrosive or high-temperature conditions. 4. Heat resistance: These castings can withstand high temperatures without losing their hardness or strength, making them suitable for applications where heat is generated or transferred, such as in industrial machinery or power plants. 5. Wear resistance: As the name suggests, the primary characteristic of wear-resistant castings is their ability to resist wear. They are designed to minimize the loss of material due to abrasion, erosion, or friction, ensuring a longer lifespan and reduced maintenance requirements. 6. Customizability: Wear-resistant castings can be customized to suit specific applications and requirements. They can be produced in various shapes, sizes, and configurations to fit different components and machinery, providing tailored solutions for wear-related challenges. Overall, the main characteristics of wear-resistant castings make them essential components in industries where wear and abrasion are prevalent, such as mining, construction, cement, and steel manufacturing. These castings help to increase the lifespan and reliability of equipment, reduce downtime, and improve overall operational efficiency.

- Q:What are the standards and certifications for special steel?

- Some of the standards and certifications for special steel include ISO 9001 for quality management systems, ISO 14001 for environmental management systems, and ISO 45001 for occupational health and safety management systems. Additionally, there are various industry-specific standards such as ASTM International, EN standards, and JIS standards that provide specifications and testing requirements for different types of special steel. These standards and certifications ensure that the special steel meets specific quality, safety, and environmental standards, and helps to establish trust and credibility in the industry.

- Q:How does special steel contribute to the automotive racing aftermarket industry?

- Special steel plays a crucial role in the automotive racing aftermarket industry by providing the necessary strength, durability, and performance required for high-performance racing vehicles. In this industry, where speed, precision, and safety are paramount, special steel offers unique properties that enable engineers and manufacturers to push the limits of performance. One key way that special steel contributes to the automotive racing aftermarket industry is through its ability to withstand extreme conditions. Racing vehicles are subjected to intense heat, pressure, and vibrations during high-speed races, which can put immense stress on various components. Special steel, with its exceptional heat resistance and high tensile strength, ensures that critical parts like engine components, transmission gears, and suspension systems can withstand these harsh conditions without compromising performance or safety. Furthermore, special steel is known for its lightweight properties, making it an ideal material for racing vehicle components. Weight reduction is a crucial aspect of racing as it directly impacts acceleration, handling, and overall performance. By using special steel, manufacturers can create lighter yet stronger components, allowing racing teams to achieve higher speeds, better maneuverability, and improved fuel efficiency. Special steel also contributes to the automotive racing aftermarket industry by offering excellent machinability and weldability. This allows for precise customization and modification of components, catering to the specific needs and preferences of racing teams. Whether it is creating custom engine blocks, exhaust systems, or chassis reinforcements, special steel provides the flexibility required to optimize performance and gain a competitive edge. Moreover, the use of special steel in the automotive racing aftermarket industry promotes innovation and technological advancements. Steel manufacturers continually develop new alloys and compositions that enhance the performance capabilities of racing vehicles. These advancements can include improved corrosion resistance, better fatigue strength, and enhanced material properties, all of which contribute to the overall performance and longevity of racing vehicle components. In summary, special steel is a vital contributor to the automotive racing aftermarket industry. Its unique combination of strength, durability, lightweight properties, and machinability enables racing teams to design and manufacture high-performance vehicles that can withstand extreme conditions. By leveraging the advantages of special steel, the industry can continue to push the boundaries of automotive racing, delivering faster, safer, and more efficient racing machines.

- Q:Can special steel be used for making food processing equipment?

- Yes, special steel can be used for making food processing equipment. Special steel, also known as stainless steel, is commonly used in the food processing industry due to its unique properties. Stainless steel is non-reactive, meaning it does not interact with food or alter its taste, odor, or color. It is also resistant to corrosion, which is essential in preventing contamination and ensuring food safety. Additionally, special steel is durable, easy to clean, and has a smooth surface that prevents the growth of bacteria. These qualities make it an ideal material for making food processing equipment such as mixing tanks, conveyors, cutting tools, and storage containers.

- Q:What are the different forging grades of special steel?

- There are several different forging grades of special steel, each with its own unique characteristics and applications. Some of the most commonly used forging grades include: 1. Carbon Steel: Carbon steel is a popular choice for forging due to its high strength and durability. It contains various amounts of carbon, which determine its hardness and toughness. Carbon steel forgings are commonly used in automotive parts, construction equipment, and machinery. 2. Alloy Steel: Alloy steel is made by adding various alloying elements to carbon steel, such as manganese, chromium, nickel, or molybdenum. This enhances its strength, corrosion resistance, and wear resistance. Alloy steel forgings are widely used in aerospace, defense, oil and gas, and power generation industries. 3. Stainless Steel: Stainless steel is a corrosion-resistant steel alloy that contains a minimum of 10.5% chromium. It is highly resistant to rust and staining, making it suitable for applications in harsh environments or where hygiene is critical. Stainless steel forgings are commonly used in the food processing, chemical, and medical industries. 4. Tool Steel: Tool steel is specifically designed for use in cutting tools, molds, and dies. It has high hardness, wear resistance, and toughness, allowing it to withstand high temperatures and heavy loads. Tool steel forgings are used in the manufacturing of drills, saw blades, punches, and various precision tools. 5. High-Speed Steel: High-speed steel is a type of tool steel that is capable of cutting at high speeds without losing its hardness. It contains additional elements like tungsten, molybdenum, or vanadium, which improve its heat resistance and wear resistance. High-speed steel forgings are used in the production of cutting tools, drills, and milling cutters. 6. Maraging Steel: Maraging steel is a low-carbon, high-nickel steel alloy known for its exceptional strength and toughness. It is heat-treated to achieve high tensile strength while maintaining good ductility. Maraging steel forgings are commonly used in aerospace, defense, and missile systems. These are just a few examples of the different forging grades of special steel available in the market. Each grade offers specific properties suited to different applications, ensuring that the right material can be selected for the desired performance and durability requirements.

- Q:What are the properties of heat-resistant steel?

- Heat-resistant steel has several key properties that make it suitable for use in high-temperature environments. Firstly, it has a high melting point, allowing it to withstand extreme heat without deforming or melting. Additionally, it exhibits excellent strength and toughness at elevated temperatures, enabling it to maintain structural integrity under thermal stress. Heat-resistant steel also possesses good oxidation and corrosion resistance, preventing it from corroding or deteriorating when exposed to oxygen or other corrosive elements at high temperatures. Finally, it has low thermal expansion, ensuring dimensional stability even when subjected to significant temperature changes. Overall, the properties of heat-resistant steel make it a reliable choice for applications in industries such as aerospace, power generation, and petrochemicals, where it can endure and perform consistently under intense heat conditions.

- Q:What are the different methods of improving the wear resistance of special steel?

- There are several methods that can be employed to improve the wear resistance of special steel. Firstly, heat treatment techniques such as quenching and tempering can be used. Quenching involves rapidly cooling the steel in a liquid medium, such as oil or water, to increase its hardness. This process forms a hardened surface layer that can resist wear. Tempering, on the other hand, involves reheating the quenched steel to a specific temperature and then cooling it slowly. This helps to reduce the brittleness caused by quenching and improve the steel's toughness, which is important for wear resistance. Another method is through alloying. Adding elements such as chromium, manganese, or vanadium to the steel can significantly enhance its wear resistance. These alloying elements form carbides, nitrides, or borides, which increase the hardness and improve the material's ability to resist wear and abrasion. Surface treatment techniques like carburizing or nitriding can also be employed. Carburizing involves introducing carbon into the steel's surface by heating it in a carbon-rich atmosphere. This forms a hardened surface layer with a high carbon content, making the steel more wear-resistant. Nitriding, on the other hand, involves diffusing nitrogen into the steel's surface, forming nitrides that increase hardness and wear resistance. Furthermore, physical vapor deposition (PVD) or chemical vapor deposition (CVD) coatings can be applied to the steel surface. PVD involves depositing a thin layer of wear-resistant material, such as titanium nitride or diamond-like carbon, onto the steel's surface using a vacuum process. CVD, on the other hand, involves depositing a wear-resistant coating by chemical reactions at elevated temperatures. These coatings provide an additional layer of protection against wear and friction. Lastly, the grain size of the steel can be controlled through processes like grain refinement or severe plastic deformation. Smaller grain sizes typically result in increased hardness and improved wear resistance. Overall, a combination of these methods can be used to enhance the wear resistance of special steel, depending on the specific application and desired properties.

- Q:How is alloy steel different from carbon steel?

- Alloy steel differs from carbon steel in that it contains additional elements, such as nickel, chromium, or molybdenum, which enhance its strength, hardness, and corrosion resistance. This makes alloy steel more suitable for applications that require high performance and durability, while carbon steel is typically used for general-purpose applications.

- Q:How does the heat treatment process affect the properties of special steel?

- The properties of special steel are greatly affected by the heat treatment process. This process involves controlled heating and cooling of the steel to modify its microstructure and, as a result, its mechanical properties. To begin, heat treatment can increase the hardness of special steel. By heating the steel to a specific temperature and then rapidly cooling it through quenching, the steel undergoes a phase transformation that boosts its hardness. This is especially advantageous for applications that demand high strength and resistance to wear, such as cutting tools or bearings. Furthermore, heat treatment can enhance the toughness of special steel. By tempering the quenched steel at a lower temperature, the brittleness caused by rapid cooling can be minimized, leading to improved toughness and ability to withstand impacts. This is crucial in applications where the steel must endure sudden shocks or impacts, like in automotive or aerospace components. Moreover, heat treatment can also improve the overall strength of special steel. Through a combination of heating, cooling, and tempering processes, the steel's grain structure can be refined, resulting in increased strength and resistance to deformation. This is particularly critical for structural applications where the steel must withstand heavy loads or extreme conditions. Additionally, the heat treatment process can influence the corrosion resistance of special steel. By subjecting the steel to specific heat treatment cycles, the formation of certain phases or chemical compounds can be encouraged, leading to enhanced resistance against corrosion or oxidation. This is essential for applications exposed to harsh environments or corrosive substances, such as in marine or chemical industries. In conclusion, the heat treatment process is essential in modifying the properties of special steel. By carefully controlling the heating, cooling, and tempering cycles, the hardness, toughness, strength, and corrosion resistance of the steel can be significantly improved. This allows for the production of special steel with customized properties to meet the specific requirements of various industrial applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

S35C Forged Alloy Steel Round Bars with Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords