RUBBER VULCANIZING ACCELERATOR·ETU(NA-22)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- 120000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chemical Name: Ethylene thiourea

Molecular Formula: C3H6N2S

Molecular Weight: 102.17

CAS NO. : 96-45-7

Executive standard: HG/T2343-92

Specification:

|

Item |

Index | ||

|

Top Grade |

First grade |

Qualified Grade | |

|

Appearance (Visual inspection) |

white powder | ||

|

Initial M.P, oC ≥ |

195.0 |

193.0 |

192.0 |

|

Loss on drying, % ≤ |

0.30 |

0.30 |

0.50 |

|

Ash, % ≤ |

0.30 |

0.30 |

0.50 |

|

Residues on 150μm sieve, % ≤ |

0.50 |

0.10 |

0.10 |

Properties: White powder. Little bitter. Density is 1.42-1.43. Soluble in water,alcohol, ethylene glycol and pyridine, do not dissolve ether, benzene, chloroform and petroleum ether. No pollution to final products. Stabilization storage

Application:: The product can be used to chloroprene rubber, Epichlorohydrin rubber, chlorinated polyethylene, etc., are particularly suited to non-curing system of the chlorine-butylamine Hopewell accelerator. Can often 100-500 oC , with the right selection system can be the best rapid curing, and the whole parade security. Its products vulcanized high tensile strength, permanent deformation small for W (54-1 type polychloroprene), a non-curing system into effect significantly. It usually with zinc oxide and magnesium oxide together with the use, mainly for industrial products, and coating lines, shoes and other clothing chloroprene rubber products.

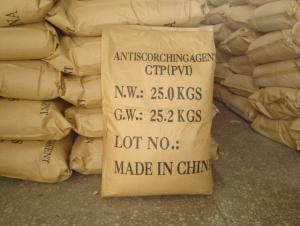

Packaging: 25kg plastic woven bag, paper with plastic film bag, Kraft paper bag.

Storage: To keep the bags tightly closed in a cool, well-ventilated place at 25 max, to place the goods on the dry wooden shelf at a height of 20cm min. And to avoid from moisture, sunshine, light and fires. The recommended max.shelf life is 2 years.

Note: The product could be ultra fine powder based on customer accurate require.

- Q:What is the color of the isobutyl silane impregnant for concrete anticorrosion?

- Should be substandard products, ask for inspection reports, manufacturers qualified to prove, or return.

- Q:How to control the impregnation conditions to obtain the active components of the various distributions of different catalysts

- Personal humor petrocatal (station contact TA) can be given in accordance with the literature of the load, the first comparison of different load methods or different starting materials (salt) of the catalyst is good or bad, determine the load method, and then examine the carrier The impact of the difference, and finally look at the impact of the load. On the second floor of the orthogonal law, very good, but for writing articles, the point too little, not suitable for mapping!

- Q:Friends, ask you a question, the capacitor of the different impregnation, capacitance What is the difference?

- These capacitors represent different dipping agents. Concrete can refer to the following answer: BKMJ --- self-healing low-voltage parallel power capacitors, mainly used to compensate for power frequency power system reactive power, adaptive and low voltage reactive

- Q:How to determine the load when the load is loaded

- The amount of active components and additives is an important factor affecting the catalytic performance of the catalyst, the active components, the amount is too small, the activity of course, with the increase in the amount of load, the activity slowly increased, but generally have An optimum value, greater than the optimal value of the time, the activity is basically the same, even due to the load is too large caused by metal sintering,

- Q:The laboratory was used as a rotary sprinkler for impregnation of the catalyst

- Laboratory to buy a dip is pulling method of coating with a CNC pull device, you can set many parameters, rising and lowering speed, coating height, immersion time, the number of coating and so on. Which rise and fall speed can reach 1um / s,

- Q:Dipping method and precipitation method to prepare the catalyst

- The non-roasting catalyst is easily lost with the solution

- Q:How to do the best volume impregnation to prepare a supported catalyst?

- Take a certain amount of material measured its saturated adsorption volume, then this part is in the back of the impregnation of the precursor solution, it can not be used to be lost? The amount of catalyst used to do not measure the saturation adsorption volume with water immersion carrier , After the completion of the carrier can also be used. Drying (station contact TA) You may have a problem with this system, CeO2 part of the water, PtCl2 aqueous solution is strong acid, the carrier will dissolve!

- Q:What is the silane impregnant

- Silane impregnant is a high performance silane product for the anticorrosive effect of reinforced concrete structures on concrete surfaces such as isobutyltriethoxysilane DB-H538, isooctyltriethoxysilane DB-H580, etc. ( China Daoer chemical industry can provide professional). Are relatively stable small molecular structure, painted to the concrete ...

- Q:The use of silane impregnants

- Silane impregnation simply means that the concrete surface is silane sprayed, first explaining what is silane. In the general seawall project, inland saline soil, freezing and thawing damage more serious, harsh environmental engineering are required to do the concrete structure of the silane impregnation anti-corrosion construction, the silane referred to here generally refers to isobutyl (alkene) triethoxysilane DB-H538 (liquid) search and isooctyl triethoxysilane DB-H580 (paste), and the content requirements are relatively high, respectively, requirements for more than 98.9% and 80%.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000;ISO14001:2004 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Lianyungang Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 135,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

RUBBER VULCANIZING ACCELERATOR·ETU(NA-22)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- 120000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords