Rubber Sheet Pipe Faced with Aluminum Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Flexible Rubber Plastic Insulation Material Product Description

Rubber plastic is a high quality heat-insulating and heat-preservation material which use but yronitrile rubber and polyvinyl chloride(NBR,PVC) as main raw materials. The production process includes mixing, tensing and continuous extruding , heating and foaming.

2.Main Features of Rubber Plastic

-Lower heat-conductivity-Higher fire-blocking performance-Damp-proof and Water-proof-Softness-Neat and -Easy to install easy handing and storage-Good flexibility and tenacity

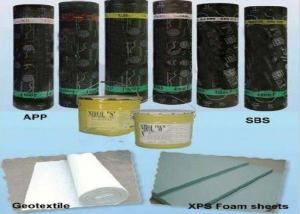

3.Rubber Plastic Images

4.Rubber Plastic Specification --Rubber Plastic Sheet

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

5.FAQ

①How about your company?A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase? In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:Is fiberglass facing fire-resistant?

- Yes, fiberglass is considered fire-resistant. It is made from a combination of glass fibers and resin, which gives it excellent heat resistance properties. Fiberglass can withstand high temperatures without melting or releasing toxic fumes. It is often used in applications where fire resistance is important, such as insulation, protective clothing, and construction materials. However, it's important to note that while fiberglass itself is fire-resistant, the materials it is used with, such as adhesives or coatings, may affect its fire-resistance properties.

- Q:What are the differences among glass wool, rock wool and mineral wool?

- Glass wool: The main raw material is glass, the fire rating of which is A-level, and the heat conductivity coefficient is 0.037, the shrinkage temperature is around 270 degrees. Uses: It has a significant cold insulation performance. Rock wool: The main raw material is basalt, the fire rating of which is A-level, and the heat conductivity coefficient is 0.040, the shrinkage temperature is around 730 degrees. Uses: It can be used in high-end engineering projects such as construction, shipbuilding, petrochemical ones. Mineral wool: The main raw material is slag, the fire rating of which is A-level, and the heat conductivity coefficient is 0.044, the shrinkage temperature is around 680 degrees. Uses: It can be used as filling and thermal insulation materials for curtain walls.

- Q:Can glass wool be used in exterior wall for thermal insulation?

- The tensile property of external wall thermal insulation materials is entirely determined by unit weight of thermal insulation materials and the mixture of binder with rock wool.

- Q:02J611-4 aluminum alloy color steel stainless steel sandwich panel door Atlas who made a thank you

- Scaffolding decoration and use, is the construction of the scaffolding, after the construction is not removed, and then as a decoration construction, do not repeat structures, do not repeat charges.

- Q:i like to put a layer of sand in roofing instead of insulation. it's fireproof and insulates better. plus it's free. how much weight can ceiling board handle? I find about 15 inches poured into the roof works fine so far. Saves me about $1600 each house built

- first sand is very heavy and will probably exceed the loading on the roof and walls the extra reinforcing you would need to make the house SAFE would far outway any savings

- Q:What is the difference between glass wool and rock wool?

- Rock wool products are refined basalt as the main raw material, high temperature melting, high-speed centrifugal equipment made of inorganic fibers, and then add a special binder and dust oil by the swing belt and through special equipment to change the fiber arrangement structure, and finally The new type of lightweight insulation materials made by curing and stereotypes can be processed into rock wool board, rock wool felt, rock wool shell and so on according to different uses.

- Q:Fiberglass Felt Polyester Powder Adhesive Details

- The chopped strand mats cut the glass precursor (sometimes with roving) into a 50 mm long, randomized but evenly laid out on a mesh belt, followed by an emulsion binder or a powdery powder. Bonding to chopped stranded mats. The chopped mat is mainly used for hand lay-up, continuous plate making and mold pressing and SMC processes.

- Q:Why is the most insulation needed in ceilings or roofs? Just wanted to know

- well insulation in general is to keep the inside temperature different than the outside. since hot air usually rises, i think it is to keep warm air form escaping in winter. also you don't usually have a heater in the attic, or air conditioning so insulation will keep the air in the attic from having an effect on the air within the house. that is my idea as to why

- Q:Whose thermal insulation performance is the best between glass wool felts and cystosepiments?

- The construction methods are different. The cystosepiments are certainly better than glass wools. But cystosepiments are rigid plates, while the glass wool felts are soft. From the thermal insulation property,

- Q:XPS Extrusion foam insulation board is a batch of how much

- . steel pipe scaffold steel pipe should be used outside diameter 48mm, wall thickness 3.5mm welded steel pipe, can also be used outside diameter 51mm, wall thickness 3.1mm welded steel pipe. The maximum length of the steel pipe used for horizontal horizontal bars shall not be greater than 2 m; the other rods shall not be greater than 6.5 m, and the maximum quality of each pipe shall not exceed 25 kg in order to be suitable for manual handling. . fasteners fastener steel scaffolding should be used for cast iron casting fasteners, the basic form of three: for vertical cross between the rods at right angles fastener, for parallel or oblique connection between the rods And the butt fasteners for the butt joint of the rods. . scaffold scaffold available steel, wood, bamboo and other materials, each piece of quality should not be greater than 30kg. Stamping steel scaffold is a commonly used scaffolding board, generally made of thick steel plate 2mm, length 2-4m, width 250mm, the surface should be anti-slip measures. Wooden footboard can be used not less than 50mm thickness of the fir board or pine production, length 3 ~ 4m, width 200-250mm, both ends should be set galvanized steel wire hoop two, to prevent the end of the wooden footboard damage. . even the wall with wall pieces of the pole and the main structure connected together, available steel pipe, fasteners or embedded parts composed of rigid wall pieces, but also can be used to pull the ribs of flexible flexible wall pieces. . the base base in the form of both plug-in and jacket type, interpolation of the outer diameter D1 diameter than the pole 2mm, jacket type diameter D2 than the pole diameter 2mm.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rubber Sheet Pipe Faced with Aluminum Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords