Rubber Seal Strips Used for Car Doors with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rubber Seal Strips Used for Car Doors with High Quality:

1. Brief Description of Rubber Seal Strips Used for Car Doors with High Quality:、

We not only can produce the rubber seal on the photo, but can also produce other similar rubber seal strips, welcome inquiry us with your drawings or sample or photos or design !

2. Main Features of Rubber Seal Strips Used for Car Doors with High Quality:

1). Environmental safety, good insulation, high temperature, low compression set, strong resilience;

2) smooth surface, uniform density foam;

3) acid, anti-aging, non-toxic;

4) good non-stick surface, good air permeability;

5) using 100 percent high-quality rubber raw materials, and rigorous testing

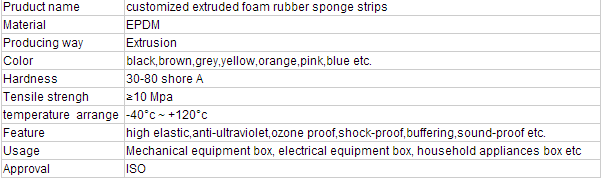

3. Main Specification of Rubber Seal Strips Used for Car Doors with High Quality:

4. Pictures of Rubber Seal Strips Used for Car Doors with High Quality

5. FAQ

1.Q: Do you produce standard parts?

A: No, We do non-standard parts only, customised parts, OEM. According to customers design, drawing or samples.

2. Q: Your MOQ?

A: We do even prototype. No MOQ, or we can say, MOQ is 1pc.

3. Q: Your Product life time?

A: Usually, rubber seal strips can be used about 10 years.

4. Q: Your Product making time?

A: Usually, within 30 days. According to the quantity,we may refund the R$D spendings

5. Q: Your sample lead time?

A: Usually 10 - 15 days after mould's done.

6. Q: Your paymet terms?

A: We accept T/T, L/C, Paypal, Escrow, Western union, Money gram, D/P, D/A, Cash, and O/A.

- Q:How to distinguish between plastic products and rubber products, toys?

- Temperature resistance, plastic, fire easily deformation, melting, rubber will not be deformed, it will not melt

- Q:When rubber products are hardened, what methods soften?

- Either hardening or vulcanization. Vulcanized rubber becomes elastic rubber. This is an irreversible process. The elastomer can be changed into a plastic regenerated rubber by the desulfurization process.

- Q:What is the difference between rubber expansion joint and rubber joint?

- The expansion joint is also called expansion device, expansion joint and compensator. It is divided into several types, such as ripple compensator, sleeve compensator, rotary compensator and square natural compensator, and also has intubation type expansion joint. Among them, the corrugated compensator is more commonly used, mainly to ensure the safe operation of the pipeline, and has the following functions: 1.. Compensating the axial, transverse and angular thermal deformation of the absorption pipeline. 2. vibration absorption equipment to reduce the impact of equipment vibration on the pipeline. The deformation of the pipeline 3., absorption of seismic subsidence.

- Q:What are the applications of rubber airbags in the automotive field?

- Rubber accounts for 5% of the total weight of automotive materials, with an average of 100200 rubber parts per car, with a total number of 200500. Along with the automobile reliability, environmental protection and energy saving requirements continue to increase, and rubber materials, product structure optimization, improve the heat resistance, low temperature resistance, long aging, oil resistance, leakage resistance, long-term fatigue, and further reduce the cost has become the main topic of the development of automotive rubber. Fluorine rubber, silicone rubber, acrylic rubber and other special heat-resistant elastic body will still be the mainstream of the future direction of the development of automobile rubber.

- Q:Several aspects of rubber aging performance and how to identify them

- Oxygen, oxygen free radical chain reaction in rubber with rubber molecules, the molecular chain rupture or excessive crosslinking caused by rubber performance. Oxidation is one of the important reasons for aging of rubber

- Q:Rubber soaked with hot water will not come out harmful substances?

- Chloroprene rubber is electrical insulation, cold resistant performance is poor, rubber is not stable in storage. Neoprene is widely used, such as the manufacture of transport belts and belts, wires and cables, and the manufacture of oil resistant hoses, gaskets, and chemical resistant equipment linings.

- Q:What are the uses of ethylene propylene rubber?

- The ethylene propylene rubber has excellent water resistance, heat resistance and weather resistance, and convenient construction etc. Therefore, ethylene propylene rubber in the construction industry is mainly used for plastic playground, waterproof materials, housing seal doors and windows, glass curtain wall sealing, sanitary equipment and pipeline seal etc.. Ethylene propylene rubber in the construction industry, the largest amount of plastic sports field and waterproofing membrane, in terms of domestic consumption, has accounted for ethylene propylene rubber total amount of 26%-28%. A waterproof roll made of EPDM that has gradually replaced other materials (such as CMS), especially waterproof rolls used in underground structures.

- Q:How is rubber made? What kind of equipment do you need? How much is it?

- The processing process of rubber is mainly to solve the process of plastic and elastic contradictions, through various means of processing, the elastic rubber has become the plastic rubber, adding various in the preparation of semi-finished products, and then through the vulcanization is has semi-finished plastic and rubber products into high elasticity and good mechanical performance the.

- Q:What are the rubber parts for the car?

- Sealing ring, toothed cutting belt, automobile synchronous belt, automobile multi wedge belt, automobile engine suspension rubber pad, shock absorber glue, anti-collision shock absorption rubber, dustproof cover, fuel tank cover, filter rubber parts, cloth (diaphragm)

- Q:What is rubber damping material?

- Butyl rubber, butyl bromide and butyl chloride are the main ones!! Need to design, sell rubber products, can find me!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rubber Seal Strips Used for Car Doors with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords