Rubber Plastic Sheet Rubber Plastic Pipe for Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Flexible Rubber Plastic Insulation Material Product Description

Rubber plastic is a high quality heat-insulating and heat-preservation material which use but yronitrile rubber and polyvinyl chloride(NBR,PVC) as main raw materials. The production process includes mixing, tensing and continuous extruding , heating and foaming.

2.Main Features of Rubber Plastic

-Lower heat-conductivity-Higher fire-blocking performance-Damp-proof and Water-proof-Softness-Neat and -Easy to install easy handing and storage-Good flexibility and tenacity

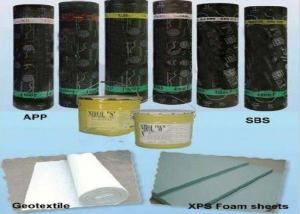

3.Rubber Plastic Images

4.Rubber Plastic Specification --Rubber Plastic Sheet

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

5.FAQ

①How about your company?A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase? In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:I would like to know which direction the one side with foil faces. The roof or the interior of the room?This is an attic room. Roof being "raw" i mean that it looks like cedar tongue in groove boards...then shingles on top of them. Which way do i face the foil side of the sheet..?thanx

- The foil side should go to the outside. I believe it's a moisture barrier.

- Q:The attic was converted into two rooms and I want to add insulation but the space between the ceiling of the rooms and the roof is about 5 inches? How should I do this?

- It sounds like you will have to use blown insulation. They will drill holes in the walls to blow the insulation in. Over time, this type of insulation will drop down or compress; so you will have to top it off over time. You might also add acoustical tile to the exiting ceiling to add a little more insulating value.

- Q:The outer wall of the pre-sprayed real stone paint, the existing cracks seepage, and now spray rain rainbow good Shi 120 can effectively waterproof it?

- 2) Lap length should not be less than 1m, should be equidistant set 3 rotating fasteners fixed

- Q:Do you need to add any time before the tile tiles before the waterproof material? If the addition of the impact on the wall of the impact of it?

- Caigang sandwich panels as one of the main structure of steel structure, the choice is also equal to the main

- Q:Can the cryogenic phase control the cooling rate?

- 1, the principle of liquid nitrogen refrigeration: storage of liquid nitrogen in the container through the liquid in the sublimation of heat to take away the heat of the workpiece heat. Liquid nitrogen refrigeration can not be reused after the need to add a new liquid nitrogen, a large range of cooling rate, cooling temperature range of 0-196 degrees C.

- Q:Glass wool can be used at zero degrees

- Ultra-fine cotton resin products, -120 ~ 400 ℃

- Q:My boyfriend has just moved into a flat in a newly converted house. He's up in the loft, and has just discovered that the roof isn't insulated.Does the landlord have a legal obligation to insulate the roof?

- To comply with UK building regulations all lofts must be insulated... Q22. How much loft insulation do I need? A22. To meet current Building Regulations you need 270mm of mineral wool insulation. 100mm between the ceiling joists and 170mm laid over the joists.

- Q:Who can tell me about the unit weight of glass wool board?

- Glass wool has a good sound absorption performance in the high-frequency sound. The main factors affecting the centrifugal glass wool' sound absorption performance are thickness, density and air flow resistance, etc. Density is the weight per cubic meter of materials. 1. with the increase of thickness, the low frequency sound absorption coefficient significantly increases, but there is little change in the high frequency (high frequency absorption is always larger). 2. thickness is the same, the unit weight increases, the low frequency sound absorption coefficient also increases; but when the unit weight increases to a certain extent, the material becomes dense, the flow resistance is greater than the optimum flow resistance, sound absorption coefficient decreases.

- Q:Which one has better noise absorption performance, the mineral wool or the glass wool?

- Glass wool has better sound-absorbing effect, and its density is smaller, and it has smaller sound reflectivity.

- Q:Is not the multi-layer membrane waterproof, the bottom of the membrane should use glass fiber mats?

- In the yin and yang angle additional layer construction better fit, polyester tire waterproofing membrane tires hard

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rubber Plastic Sheet Rubber Plastic Pipe for Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords