Rubber Extrusion Tubing Prod

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Meters m

- Supply Capability:

- 10000 Meters per Day m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

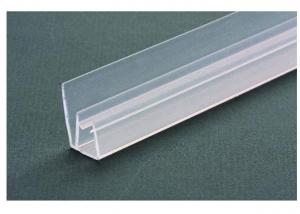

Specifications of Rubber Extrusion Tubing Prod

1.Professional OEM & Exporter

2.Professional service.Custom is God

3.Favorable price & good quality

Type of Rubber Extrusion Tubing Prod

1.Sponge/Foam Extrusion.

2.Solid/compact Extrusion.

3.Co-extruded seal strip.

4.PVC&Rubber compound extrusion.

5.All these can be with metal insertion.

Features of Rubber Extrusion Tubing Prod

Widely used in industry,agriculture,including building,automotive sealing profiles, sealing or decorating of windows, doors, curtain walls, cars etc,avoiding dust,water or air to leak inside the cabin,as

it's good ozone-resistant,chemical resistant,Weather&temperature resistant and has excellent

appearance in flexibility Anti-aging, antiradiation.

Range of Rubber Extrusion Tubing Prod

Manufacture wide range of rubber profile,rubber seals,rubber strip, tubing, cord or custom rubber extrusion

shapes for Auto industry,mechanical,construction,etc ,the extrusions also can be made in PVC. Our rubber

extrusion includes but not limited , D sponge Seal, Rubber bulb, rubber U channel, T section seal, Edge Trim, Flock

lined rubber, flat square sponge rubber, window rubber,weather strip etc.Custom design could be available

General data of Rubber Extrusion Tubing Prod

Material: EPDM, Nitrile(NBR), Neoprene(CR), Silicon, Viton, SBR, Natual rubber and various other basic raw materials.

Hardness: From 35 to 85 Share A.

Temperature resistance:-50 to +260 Degrees Centigrade (up to 300C for short periods).

Various color are available,like black,red,white,blue.etc.

Grade:Industrial grade;Food grade(FDA approval).Medical grade.

Size available:1mm to 150mm high and width

Length:continous.

Different sections as per your sample or drawings,do believe that we can supply competitive price &quality with best service.

- Q:How to remove the silver paint on the black rubber strip and black plastic board?

- Who painted the paint, the decorative strips and the paint on the door were much harder to paint than the bright surface. The seats were diluted with the thinner and the washing would be a little faded

- Q:How much is the Elantra car wiper size?

- The wiper is often used, and rubber which is easy to wear, so we should often check, lift the wiper, fingers after cleaning the rubber wiper blade on the touch, if rubber aging, hardening and crack, then it should replace the wiper rubber strip the. If the vehicle is exposed for long periods of time, the wiper should be lifted and a soft object underneath. Or stand up, too, so that rubber strips can be over aged. In rainy days, when the subject, should put the wiper up, avoid frozen frozen wiper.

- Q:What are the mechanisms of the action of the eye plate and the cutting ring of the concrete pump?

- The S tube valve is composed of an eyeglass plate, a cutting ring, a rubber spring, a special-shaped nut, a transition sleeve, a sealing member, a size bearing and a S pipe welding body.The glasses plate and the cutting ring mainly play the following roles:The sealing function: they mainly work with spring and rubber, through the pressure self balancing and rubber spring automatic gap compensation, the floating cutting ring has self sealing effect, thereby increasing the conveying pressure s tube valve.

- Q:What's the rubber tube on the empty filter for the motorcycle?

- Scooter engine case and even a larger pipe, the ventilation tube.

- Q:What chemicals have been added to the wiper bars?

- Automobile wipers should be of good quality and durability; now wiper manufacturers are grinding costs, so quality will decline a lot, and the average life is 4~6 months;

- Q:Why doesn't the bumper of the car need elastic material like rubber?

- In fact, many foreign models have just arrived in the country, the use of rubber bumpers, such as: old Santana, Chevolet Spaak and so on, are used in this black rubber bumper.But although the bumpers are very practical, they seem to be of low quality. The car manufacturers use glass fiber reinforced plastic bumpers in order to improve the image of the car and to make the body color and cost.

- Q:General car ordinary car had a puncture can continue to open it, most can run far?

- The tyre is not recommended to continue under low pressure. (please check the cause of the tire depression; for example: nail sticking, cutting, rubber aging, cracking, etc.).

- Q:What material is the rubber hose on the tank truck?

- Any of various steels that contain less than 2.11% of the mass of carbon but contain no alloying elements. Sometimes referred to as plain carbon steel or carbon steel.Carbon steel, also called carbon steel, refers to an iron carbon alloy with a carbon content of less than 2.11% Wc.Carbon steel, in addition to carbon, usually contains a small amount of silicon, manganese, sulfur and phosphorus.

- Q:What is the swelling glue used in automobiles?

- Expansion rubber is a kind of auto expansion adhesive tape and film made of synthetic rubber and resin as base material. It has excellent oil surface adhesion, operability, high expansion rate, filling property, elasticity and good adhesion.

- Q:Lianyi auto rubber skid chain, okay?

- After using that previously used Dichotomanthes simply suck.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang,China (Mainland) |

| Year Established | 2004 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | North America Western Europe |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai,Ningbo |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English |

| b)Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 7 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | average |

Send your message to us

Rubber Extrusion Tubing Prod

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Meters m

- Supply Capability:

- 10000 Meters per Day m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords