Rubber Door Seal with High Quality and Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rubber Door Seal with High Quality and Low Price:

1. Brief Description of Rubber Door Seal with High Quality and Low Price:

Our products mainly include rubber part,rubber seal,silicone rubber, rubber extrusion,rubber mat, rubber sheet etc. Now our products have been exported to the USA, Argentina, Chile, England, Germany,Sweden, Italy, Poland, Israel, Singapore, Korea and South Africa, totally over 30 countries.

2. Main Features of Rubber Door Seal with High Quality and Low Price:

1) We can customize your brands, and provide high quality products with competitive price.

2). We provide thoughtful, prompt and safe services to every customer.

3). Offer Samples in FREE!

4). More order, More discount!

5). Provide Cheap & Safe Shipping or Express!

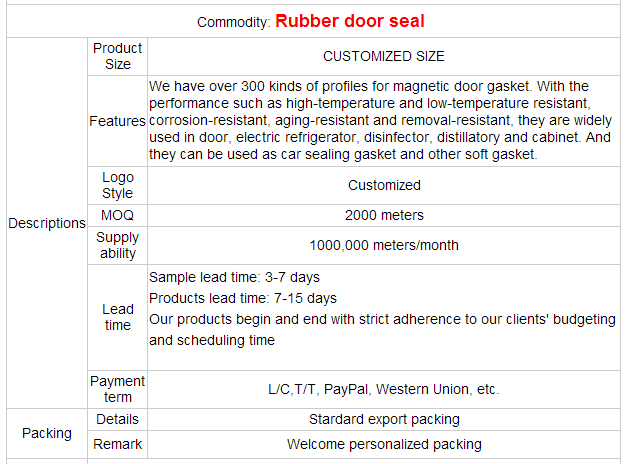

3. Main Specification of Rubber Door Seal with High Quality and Low Price:

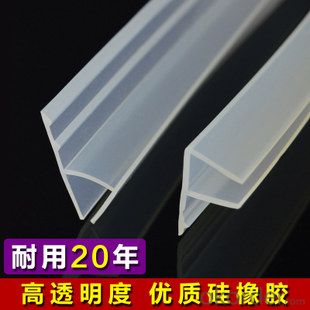

4. Pictures of Rubber Door Seal with High Quality and Low Price:

5. FAQ

1.Q: Do you produce standard parts?

A: No, We do non-standard parts only, customised parts, OEM. According to customers design, drawing or samples.

2. Q: Your MOQ?

A: We do even prototype. No MOQ, or we can say, MOQ is 1pc.

3. Q: Your Product life time?

A: Usually, rubber seal strips can be used about 10 years.

4. Q: Your Product making time?

A: Usually, within 30 days. According to the quantity,we may refund the R$D spendings

5. Q: Your sample lead time?

A: Usually 10 - 15 days after mould's done.

6. Q: Your paymet terms?

A: We accept T/T, L/C, Paypal, Escrow, Western union, Money gram, D/P, D/A, Cash, and O/A.

- Q:Properties and specific uses of various rubbers

- Synthetic rubber is made by synthetic methods, and different kinds of rubber can be synthesized with different raw materials (monomers). Such as, butadiene rubber, chloroprene rubber, styrene butadiene rubber and so on. The yield of synthetic rubber has greatly exceeded that of natural rubber, of which the largest yield is styrene butadiene rubber.

- Q:How to solve the spray of rubber products?

- Rubber spray, including rubber surface spray and surface spray. Spray cream is a liquid or solid compounding agent made from rubberThe phenomenon of internal migration to the rubber surface is the precipitation of the rubber compounding agent.

- Q:What kind of rubber coated aluminum alloy (metal) better

- This is still a problem, the metal is with the rubber, and what rubber can wrap metal, regardless of which kind of metal can and rubber good bonding, the key is what your customers need to use what kind of rubber

- Q:Is carbon black and conductive carbon black used in rubber?

- Conductive carbon black is a kind of carbon black used in rubber. After adding rubber, it can make the rubber which has not poured electricity have conductivity characteristics, but the resistivity is higher, and it can't be used as conductor for current load

- Q:What are the common rubber products, please tell me

- Rubber products mainly include tires, sidewall, rubber strips and inner tubes, as well as parts of automobiles. They are made of wires, cables, wrapping and high voltage and extra high voltage insulating materials. They can also make rubber shoes and guardOther light colored products, such as raw materials, and other general industrial rubber products, cushioning materials, conveyor belts and belts, oil resistant hoses, gaskets, and chemical resistanceCorrosion equipment lining.

- Q:Why does rubber stink?

- The word "rubber" comes from the Indian language "cau-uchu", meaning "weeping tree"". Natural rubber is flowing out from the Hevea latex when tapping after solidification and drying process. In 1770, British chemist J. Priestley discovered that rubber could be used to erase pencil writing. The material used at that time was called rubber, which has been used so far. The molecular chain of rubber can be crosslinked, and the crosslinked rubber can recover quickly when it is deformed by external force, and has good physical and mechanical properties and chemical stability. Rubber is the basic raw material of rubber industry. It is widely used in making tyres, rubber hoses, tapes, cables and other kinds of rubber products.

- Q:High strength rubber repairing agent

- At present, more commonly used high strength rubber repair agent, mostly imported. Like some industrial and mining belts in the repair of broken belts, the choice of sk358 such a two-component rubber repair agent used, the effect is really better.

- Q:What kinds of vulcanized rubber do you have?

- According to the appearance of rubber: rubber can be divided into solid rubber (also known as dry rubber), emulsion rubber (referred to as latex), liquid rubber and powder rubber four categories.

- Q:Why is natural rubber a strategic material?

- Rubber is an important strategic material, in the national defence application is very extensive, for example, a tank with more than 800 kg of general rubber; thirty thousand ton warship with sixty-eight tons of rubber, military equipment, air force facilities, almost all defense engineering rubber footprint. The use of rubber made ship, tent, warehouse and protective equipment, clothing etc. there are many varieties of bath water. As for the anti - tip technology needs high temperature, low temperature, oil resistance, high vacuum resistance and other special properties of the rubber, the constitution of 0 products is indispensable. With the development of national defense modernization, rubber, which is capable of resisting the temperature range of minus 100-400 DEG C and capable of resisting various acids, bases and oxidants with special properties, is being developed and manufactured.

- Q:How do ordinary NBR and EPDM materials differ?

- Difference: EPDM density is lower than NBR, the appearance of EPDM is transparent or white, and NBR is yellow or white yellow.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rubber Door Seal with High Quality and Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords