Round Steel 5115 Steel Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Round Steel 5115 Steel Bars

Products Details

1. good mechanical property

2. high temper resistance

3. hardened and tempered steel

4. 12-250mm/200~650mm

| Material standardized according to | 5115 round steel round bar |

| Unfinished products manufactured | Pipes - profiles - squares |

| Properties | Excellent mechanical features - good workability on high-speed automatic machines with easy fragmentation of the shavings made by the tool |

| Typical applications | used for making heavy loading and sectional gear shaft,gear,connecting rod,eccentric shaft,rear axle shaft of car,parts of steam turbine,etc |

Chemical composition (%)

| C | Cr | Si | p | Mn | Ni |

| 0.37~0.45 | 0.90~1.20 | 0.17~0.37 | ≤0.035 | 0.90~1.20 | ≤0.030 |

Specifications: (approximate values)

| Quenching Temp | 860 ±15 °C |

| Cool Media | Oil |

| Tempering Temp | 600 ±15 °C |

| Cooling Media | air |

Mechanical features

| Tensile Strength (MPA) | Yield Strength(MPA) | Elongation(%) | Reduction In Area(%) | Impact Energy(J) | Hardness(HB) |

| ≥1080 | ≥ 930 | ≥ 12 | ≥ 45 | ≥ 63 | ≥217 |

Products Show

Product Overviews

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 |

GB/SAE/JIS/DIN

|

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

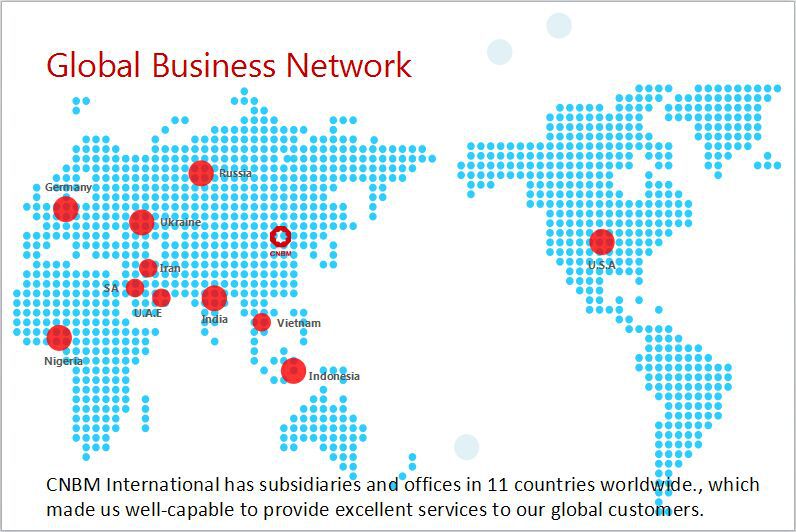

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q:What are the different types of tests performed on steel round bars for quality control?

- There are several types of tests performed on steel round bars for quality control. These include visual inspection, dimensional checks, surface roughness evaluation, hardness testing, tensile testing, impact testing, and chemical composition analysis. These tests help ensure that the steel round bars meet the required quality standards and are fit for their intended applications.

- Q:Can steel round bars be used for making tie rods?

- Yes, steel round bars can be used for making tie rods.

- Q:What kind of nuts do you need for round 20 rounds?

- Common materials for 301, 304, 303, 316, 316L, 304L, 321, 2520, 201, 202 and so on. Specifications are expressed in diameter, such as "50", which means a round bar of 50 millimeters in diameter. Round bar is divided into three parts: hot rolling, forging and cold drawing. Standard Specification for hot rolled round steel is 5.5-250 mm.Stainless steel round bar has a broad application prospect, and is widely used in hardware, kitchenware, shipbuilding, petrochemical, machinery, medicine, food, electricity, energy, aerospace and other architectural decoration. Equipment, chemicals, dyes, paper making, oxalic acid, fertilizer, etc.; equipment for photography, food industry, coastal areas, ropes, CD poles, bolts, nuts, etc..

- Q:How are steel round bars used in the construction of offshore structures?

- Steel round bars are commonly used in the construction of offshore structures due to their high strength and durability. These bars are typically made from carbon steel or alloy steel, which are known for their excellent mechanical properties. In offshore construction, steel round bars are primarily used to provide structural support and reinforcement. They are used in various applications, such as the construction of oil rigs, offshore platforms, pipelines, and subsea structures. One of the key uses of steel round bars is in the fabrication of piles. Piles are long, cylindrical structures that are driven into the seabed to provide a stable foundation for offshore structures. These piles are typically made from steel round bars due to their ability to withstand the harsh marine environment and high loads. Steel round bars are also used in the construction of offshore platforms. These platforms are large, elevated structures that provide a workspace for oil and gas exploration and production activities. The steel round bars are used to create the framework of the platform, forming the main structural elements such as columns, beams, and trusses. These bars are often welded or bolted together to create a strong and rigid structure capable of withstanding extreme weather conditions and heavy loads. Furthermore, steel round bars are utilized in the construction of pipelines that transport oil and gas from offshore wells to onshore facilities. These bars are used to create the pipeline supports, ensuring that the pipeline remains stable and securely fastened to the seabed. In conclusion, steel round bars play a vital role in the construction of offshore structures. Their high strength, durability, and ability to withstand harsh marine environments make them an ideal choice for providing structural support and reinforcement in offshore construction projects.

- Q:Are steel round bars suitable for use in the mining industry?

- Yes, steel round bars are suitable for use in the mining industry. Steel round bars are known for their strength and durability, making them ideal for use in the mining industry where heavy-duty equipment and machinery are utilized. These bars can be used for various applications such as shafts, support beams, and structural components in underground mines, open-pit mines, and processing plants. Steel round bars are capable of withstanding high loads and pressures, making them suitable for harsh mining environments. They have excellent tensile strength and can withstand extreme temperatures, making them resistant to wear, abrasion, and impact. This is crucial in mining operations where equipment is subjected to heavy loads, vibrations, and constant movement. Moreover, steel round bars can be easily welded, fabricated, and machined according to specific requirements, making them versatile and adaptable to a wide range of mining applications. They can be customized to different sizes, lengths, and shapes, ensuring a perfect fit for various mining equipment and structures. In addition to their strength and versatility, steel round bars also offer cost-effectiveness and long-term value. They have a long lifespan, require minimal maintenance, and can withstand the harsh conditions typically found in mining operations, reducing the need for frequent replacements or repairs. Overall, steel round bars are a reliable and suitable choice for the mining industry due to their strength, durability, versatility, and cost-effectiveness. They provide the necessary support and structural integrity required for mining operations, ensuring the safety and efficiency of the industry.

- Q:Can steel round bars be used for making renewable energy systems?

- Yes, steel round bars can be used for making renewable energy systems. Steel is a versatile material that is commonly used in various industries, including renewable energy. It is strong, durable, and resistant to corrosion, making it ideal for constructing frameworks, support structures, and components of renewable energy systems. Steel round bars can be used to manufacture wind turbine towers, solar panel frames, and support structures for hydroelectric power systems. Wind turbine towers require a strong and stable structure to support the weight of the turbine and withstand the forces of wind. Steel round bars provide the necessary strength and stability, ensuring the safety and efficiency of the wind turbine. Similarly, solar panel frames need to be sturdy enough to support the weight of the panels and withstand harsh weather conditions. Steel round bars can be used to construct durable frames that can securely hold the solar panels in place. In the case of hydroelectric power systems, steel round bars can be used to build support structures for various components, such as turbines, generators, and penstocks. These structures need to withstand the immense pressure and force of water flow, and steel's strength and durability make it an excellent choice for this purpose. Overall, steel round bars are a reliable and commonly used material in the construction of renewable energy systems. Their strength, durability, and resistance to corrosion make them suitable for various applications, helping to ensure the long-term viability and sustainability of renewable energy sources.

- Q:How are steel round bars used in the construction of high-rise buildings?

- Steel round bars are commonly used in the construction of high-rise buildings due to their strength, durability, and versatility. These bars are typically made of carbon steel, which has excellent mechanical properties and can withstand high loads and pressures. In the construction of high-rise buildings, steel round bars are primarily used in reinforced concrete structures. They are commonly used as reinforcement in concrete beams, columns, and slabs. The bars are embedded in the concrete to provide additional strength and stiffness to the overall structure. One of the main advantages of using steel round bars is their ability to resist tension forces. Concrete is strong in compression but weak in tension, so the steel bars act as tension reinforcement, preventing the concrete from cracking or failing under tension loads. This helps to enhance the structural integrity and overall safety of the building. Additionally, steel round bars can be easily bent, shaped, and welded, allowing for flexible design and construction possibilities. They can be customized to specific lengths and diameters to suit the requirements of the building project. This versatility makes them ideal for constructing various structural elements, such as beams and columns, which need to be precisely engineered to support the weight and stresses of a high-rise building. Moreover, steel round bars have excellent resistance to corrosion, which is crucial in the construction of high-rise buildings that are exposed to various environmental elements. The corrosion-resistant properties of steel ensure the long-term durability and lifespan of the structure. Overall, steel round bars play a vital role in the construction of high-rise buildings by providing strength, durability, and flexibility to the reinforced concrete structures. They enhance the overall structural integrity, safety, and longevity of the building, making them an essential component in modern construction practices.

- Q:What are the different cutting methods for steel round bars?

- Depending on the specific requirements and available equipment, there are various cutting methods that can be used for steel round bars. Here are some of the most commonly used ones: 1. Sawing: Sawing is a traditional and basic method of cutting steel round bars. It involves using a saw blade with teeth to cut through the metal. This can be done manually with a hacksaw or with the assistance of a bandsaw or circular saw. Sawing is a versatile method suitable for both small and large-scale cutting projects. 2. Shearing: Another commonly used method is shearing. It utilizes a shear machine or hydraulic press to apply high force and cut through the metal. Shearing is particularly effective for cutting thick or heavy-duty steel bars. 3. Abrasive cutting: For steel round bars with irregular shapes or precision cutting projects, abrasive cutting is often employed. This method involves using an abrasive wheel or disc to grind away the metal and create the desired cut. It can be performed manually with a handheld grinder or with the assistance of an abrasive cut-off saw. 4. Flame cutting: Also known as oxy-fuel cutting, flame cutting employs a combination of oxygen and a fuel gas to create a high-temperature flame that melts and cuts through the steel. This method is commonly used for cutting thick steel bars or shaping metal. 5. Plasma cutting: Plasma cutting is an advanced method that utilizes a plasma torch to cut through the steel. The torch generates a high-velocity jet of ionized gas, which melts and removes the metal. Plasma cutting is often preferred for precision cutting due to its greater control and ability to produce cleaner cuts compared to other methods. It is important to consider factors such as the thickness and hardness of the steel round bar, desired precision of the cut, and available equipment when selecting a cutting method. Consulting with a professional or experienced metalworker is recommended to determine the most suitable method for a specific project.

- Q:Can steel round bars be used for making kitchen utensils?

- Kitchen utensils can indeed be made using steel round bars. Steel, being a robust and long-lasting material, is frequently employed in the manufacturing of kitchen utensils because of its ability to withstand corrosion, heat, and chemical harm. By effortlessly shaping and molding steel round bars, they can be transformed into a variety of utensils like spoons, forks, knives, and ladles. Moreover, steel utensils are non-reactive, ensuring that they do not release any harmful substances into food, thereby offering a safe option for cooking and food preparation.

- Q:What are the advantages of using nickel-tungsten alloy steel round bars?

- There are several advantages of using nickel-tungsten alloy steel round bars: 1. High strength and durability: Nickel-tungsten alloy steel round bars have excellent strength and durability properties. This makes them suitable for applications that require resistance to wear, fatigue, and high-temperature environments. 2. Corrosion resistance: The addition of nickel in the alloy enhances its corrosion resistance properties. This makes nickel-tungsten alloy steel round bars highly resistant to various corrosive environments, including acids, alkalis, and seawater. 3. Excellent heat resistance: Nickel-tungsten alloy steel round bars exhibit excellent heat resistance, which allows them to maintain their mechanical properties even at elevated temperatures. This makes them ideal for applications that involve high-temperature environments, such as in the aerospace and automotive industries. 4. Good electrical conductivity: The inclusion of tungsten in the alloy enhances its electrical conductivity properties. This makes nickel-tungsten alloy steel round bars suitable for applications that require good electrical conductivity, such as in electrical connectors and electronic devices. 5. Machinability: Nickel-tungsten alloy steel round bars are relatively easy to machine, allowing for the production of complex shapes and designs. This makes them versatile and suitable for various manufacturing processes, including machining, forging, and welding. 6. Cost-effective: Despite their advantageous properties, nickel-tungsten alloy steel round bars are relatively cost-effective compared to other high-performance alloys. This makes them a cost-efficient choice for many industries, as they offer a balance between performance and affordability. Overall, the advantages of using nickel-tungsten alloy steel round bars make them a preferred material for a wide range of applications, including aerospace, automotive, electrical, and manufacturing industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Round Steel 5115 Steel Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords