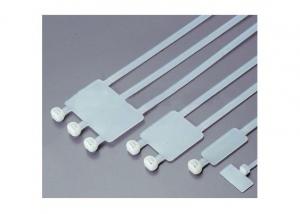

Round Head Ties

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 Pieces pc

- Supply Capability:

- 60000 Pieces per Day pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

*UL, GL, ABS, Lloyd's Register approved product.

*Min. loop tensile strength:114kg (250 lbs)

*High tensile strength cable ties.

*Extra heavy duty ties for application where higher tensile strength is required.

*One-piece construction for consistent performance and reliability.

*Lowest threading force of any one-piece cable tie in the industry.

*Recognition/ certification: UL, ABS, Lloyd's Register, GL

*RoHS compliant. Halogen free material.

*Material: Polyamide 6,6, UL94 V2

*Color: All colors are available

- Q:Elevator monitoring video line tied to the accompanying cable which side is good? How to determine which side of the cable is strong, there are different elevator brand approach is not the same? Such as Otis Elevator and Mitsubishi Elevator. Question added: online There are articles on both sides is not the same, while the high voltage interference is also large, but did not say how to identify more

- The voice patch panel is mainly used for the termination, installation and management of voice cables between wiring closures and equipment. There are two kinds of installation with a pair of legs and a backplane; from 50 pairs to 200 pairs of selected voice telephone points; with label folders and paper labels; another 4 pairs and 5 pairs of cable and cable management ring Product optional; in line with ISO / IEC: 2002 second edition of the standard.

- Q:What is the belt that is bound to the motorcycle line?

- 4.3.4 Plate thickness Steel tray, ladder allows the minimum sheet thickness See Table 9

- Q:What are the precautions for using the cable mesh and how to use it?

- No instructions are clearly stated or allowed. In the "Code for Design of Electric Power Cables" (GB-2007), the provisions of 5.1.3 stipulate that if the number of cables in the same channel is large, if the laying of the multi-layer bracket on the same side, the following provisions shall be met: High to low power cables, strong to weak control and signal cables, communication cables "top to bottom" in the order. When the horizontal channel contains more than 35kV high-voltage cable, or to meet the introduction of the cabinet tray to meet the requirements of the bend radius requirements, should be "bottom-up" in order. In the same project or the cable channel extends to different projects, should be arranged in the same order. 2 bracket space by the channel space constraints, 35kV and below the adjacent voltage level power cables can be arranged in the same layer of support, 1kV and below the power cable can also be with the strong control and signal cable configuration in the same layer of the bracket. 3 The work of the same important circuit and the backup cable should be arranged on the different layers of the brackets. It is possible to note that it is restricted by passage space from section 2. If you really want to lay together, it should be noted that 10kV cable can not use single-core cable, you need to use three-core cable.

- Q:The elevator has 23 floors. But I have not installed before. I would like to ask how to install. How does the video line go? Thank you more

- Wire selection of the best, the best use of elevator dedicated line or 8 minutes signal line, many people think that the reason why the main purpose of this wire is anti-interference, in fact, there is an important reason is that the wire often in motion, What is the core? The installation of dedicated elevator cameras often have openings, a lot of people are very difficult things Oh, and some high-end elevator openings are not good, the material is very hard, and often there are several layers of material, the hole size to master, small We can expand, big on the trouble; pay attention to anti-interference. When the elevator starts, the surge is very scary. And the camera is not much relationship, and your construction level and the relationship between the wire; installation time and the elevator workers must be, this is still more dangerous. Not only the construction workers are dangerous, there may be endangering others. There was a building in the elevator monitoring, elevator workers to stop the elevator, the construction staff in the work, but do not know why, the top of the elevator door opened, there is a buddy did not see, directly into the elevator inside, Empty; with the cable that deal with the best, and the old elevator more exchanges about. Remember not to take the elevator from the top of the elevator overhaul the power supply, infuriated infinity. Do not waste the wire bar. There is a small skill of negotiation. Elevator inside the monitoring is difficult to effect, and must be clear in advance and Party A, do not let Party have a high expectations, this small area of ??the screen feeling certainly no outdoor large area of ??the effect of space to be faster.

- Q:How does the geothermal switch above the sensor line pick up?

- Find the relevant units ah, such as the mining bureau ah, will be issued by the relevant acceptance report can be produced

- Q:Will the power cord wiring with what is called, how the insulation effect

- There is no difference between BTTZ25 square can only do single core

- Q:The use of composite heat - shrink tape

- Composite insulation heat shrink tape (cable repair heat shrink zone) Operating Instructions

- Q:Wire diameter of 15MM current transformer model for the BH-0.66- / 5LMK-0.66SDH-0.66 wear the core is very urgent online Thank you more

- Speed does not come to generally start the capacitor (capacity reduction) and centrifugal switch (open circuit) problem, of course, mechanical problems can also lead to can not start If you start again or the same as the first case, or stop a few minutes later is the same situation, you must focus on checking the mechanical failure (bearing) running capacitor burned should be a problem with the quality of the capacitor (pressure is not enough)

- Q:Hand block the trip switch, do not alarm, but with the manual mode to move the X axis will be normal alarm. The Solve the problem added: Occasionally there will be "overstep-lX" more

- Prepared a little more goods, like the new parts of the price is not low can not prepare, now delivery customers can understand. Piecemeal things as long as they have to use some, the price is not expensive, delivery is not worth. The key is the tool class of the first ready, good things must be the first thing to do it Hammer, plug, self-tapping, stent, needle nose pliers, screwdriver, tool kits, engineering ladder, such things have to have ah. Walkie talkie a little more, a pair of children enough. We are peers, you can list a detailed list of I help you see.

- Q:Hello, may I ask, what norms do you have on the shelf?

- The diameter of the protective tube depends on all the cross-sectional area of the cable. It is usually required that the total cross-sectional area of the cable passing through the cable can not be greater than two-thirds of the area of the hole in the protective tube.

Our facilities are equipped with over 150 injection molding machines to produce full line of cable ties, stainless steel ties, wiring terminals, wiring ducts, flexible conduits, adaptors, and so on. The number of employees worldwide is around 1,500. We welcome customers from the entire world to cooperate with us.

1. Manufacturer Overview |

|

|---|---|

| Location | Taiwan |

| Year Established | 1976 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia Domestic Market |

| Company Certifications | ISO 9001:2008;ISO 14001:2004;ISO/TS 16949 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Laem Chebang/Thailand,Bangkok/Thailand,Donnguan/China |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English, Chinese, Spanish, Japanese |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | High and/or Average |

Send your message to us

Round Head Ties

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 Pieces pc

- Supply Capability:

- 60000 Pieces per Day pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords