Rough Top Diamond Surface PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

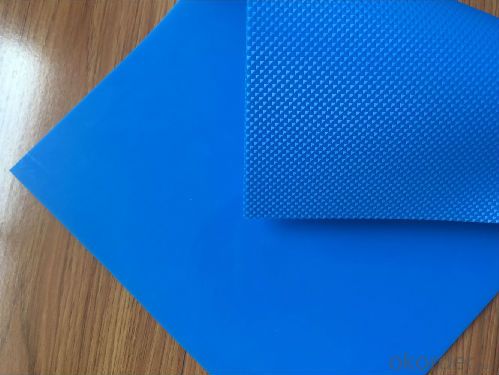

Rough Top Diamond Surface PVC Conveyor Belt

PVC Conveyor belt uses polyester fabrics as reinforcing materials, mainly used for conveying light, medium quality materials, suitable for use on the conveyor systems.

Conveyor Belt is manufactured in both white, transparent & blue provide excellent oil & greaseresistance. Our hygienic food belt range is available with varioustop & bottom cover finishes & hardness. Multiply Hygienic PVC& PU Conveyor Belts are available with either high gloss smooth PVC/PU, PVC/PU cover or bare polyester top covers.

Applications & features:

It is widely used in the assembly lines in the areas of food processing, pharmaceutical, electronics, cigarette, printing

Product features: hard wearing, good tensile strength, long service life.

Product specification: One fabric- One rubberized, Two fabric- Two rubberized, Three fabric- three rubberized,ect

Forms of joints: tooth-shaped, stepped&angled, or metal buckle

Colors:

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness:

PVC (1~7mm) PU (0.8~4mm)

Appearance:

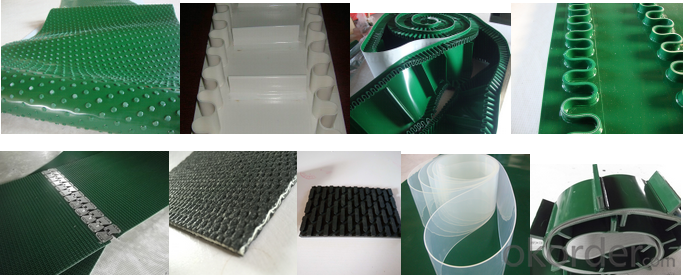

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Application:

Subsequent machining technology:

it can add baffle, skirt, sponge, guide bar and etc.

Packaging & Shipping

1.Free for samples, Door-to-Door.

2. By Air or by Sea for batch goods, Airport/ Port receiving.

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time:Based on customers' quantity. In general,25 days for batch goods.

Product photos:

Pls contact me freely if any inquiry,thank you!

- Q:Can olive nets be used for both small and large-scale olive tree nurseries?

- Yes, olive nets can be used for both small and large-scale olive tree nurseries. Olive nets are versatile and can be customized to fit various nursery sizes. They provide protection against birds and other pests, promote optimal sunlight exposure, and facilitate proper air circulation, making them suitable for both small and large-scale nurseries.

- Q:How can plastics be produced? In several ways?

- Plastic molding is the process of making final plastics from polymers made from synthetic resin manufacturing plants. Processing methods (often referred to as plastic primary processing) include compression molding (extrusion molding), extrusion (extrusion), injection molding (injection molding), blow molding (hollow forming), calendering, etc..

- Q:Electric kettle is plastic, okay?

- In addition, plastic electric kettle, only the outer shell is made of plastic, the liner is used in stainless steel, but the electric kettle in the heating process, the stainless steel liner temperature will become very high, the external plastic shell may appear a little taste in the heat, but this kind of the taste is very slight, generally do not produce what harm to the human body.

- Q:Can olive nets be used on olive trees grown in greenhouses?

- Yes, olive nets can be used on olive trees grown in greenhouses. Olive nets are commonly used to protect the olives from birds and other pests, and this protection is equally applicable to olive trees grown in greenhouses. The nets can be installed over the trees to prevent any potential damage or loss of the olives.

- Q:Are olive nets reusable?

- Yes, olive nets are reusable.

- Q:What are the codes for the plastics and plastics industries in the industry?

- Manufacturing, plastic packing box and container manufacturing, plastic shoes manufacturing synthetic leather, plastic industry is in plastic processing as the core, a whole including plastic resins, additives and additives, plastics processing machinery and tooling. The future of domestic plastic products market mainly focuses on agricultural plastic products.

- Q:How do olive nets prevent olives from bruising?

- Olive nets prevent olives from bruising by creating a protective barrier between the olives and the ground. The nets catch the olives as they fall from the tree, preventing them from making direct contact with the hard surface. This reduces the chances of bruising and damage to the olives, ensuring a higher quality yield.

- Q:Can olive nets be used for olive trees in arid climates?

- Yes, olive nets can be used for olive trees in arid climates. Olive nets provide shade and protect the trees from excessive sun exposure, which can be beneficial in arid regions where the temperatures are high. Additionally, olive nets can help reduce water evaporation from the soil and prevent wind damage, thus aiding in the water conservation efforts in arid climates.

- Q:Is plastic bath safe?

- If you're sure, try it directly and see if any chemicals are poisonous. Don't worry about that. You don't have to drink it. Although some plastics break down toxic substances when heated, it's in high temperature

- Q:How does an olive net affect the overall water usage in the olive grove?

- An olive net can significantly reduce water usage in an olive grove. By placing the net over the trees, it helps retain the moisture in the soil by preventing evaporation. This means that less water is required for irrigation, as the net helps maintain a more consistent and efficient water supply for the olive trees.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rough Top Diamond Surface PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords