Rotary Kiln/ Shaft Kiln Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rotary Kiln/ Shaft Kiln Calcined Bauxite

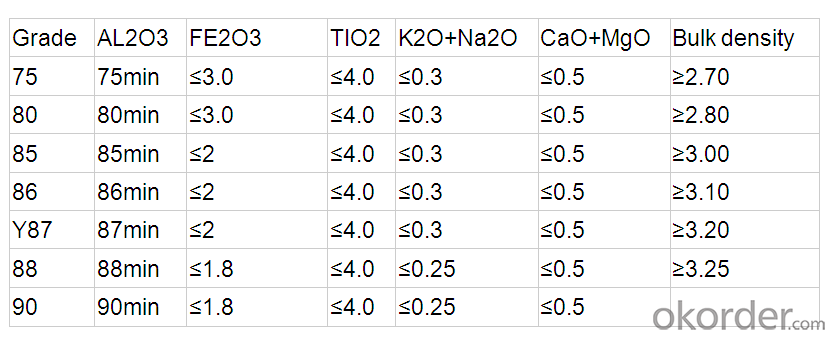

Specifications

1,Manufacturer-Direct sale

2,Good fireproof insulation

3,High bulk density

Our Advantages;

1. We have substantial experience for material manufacture and export.

2. We establish a long-term relation of cooperation with raw material supplier, so we can offer you the best quality and price.

3. We have equipped 8 production lines and skilled workers to make the quality best.

4. We can control strictly quality at factory and third party testing institutions quality inspection.

5. We can also offer you the related test report, both at factory and the third party testing institutions.

6. We have sufficient manufacturing capability to deliver the goods safely and timely.

7. We can pack in 25kg bags, 1mt big bags, 1.25mt big bags or as your request. We can also pack with pallet.

8. We have professional service team keep customers informed from delivery to discharge.

Product Description:

High grade calcined bauxite used for raw material of kinds of refractory products and monolithic series.

Usage

1. Aluminium metallurgy

2. Precision casting / Investment casting:

bauxite grog fines can be made into mold for precision casting.

3. Refractory: high alumina bauxite’s refractoriness can reach 1780°C.

It is charactered by good chemical stability and mechanical performance. (Al2O3 ≥48% with low Fe2O3)

4. Aluminium silicate refractory fiber: The high alumina bauxite grog can melt under 2000°C-2200°C in the electric arc furnace.After a series of processing, it can become aluminium silicate refractory fiber,

which can be made into fiber blanket, plate,cloth.

5. Mixing magnesia and bauxite grog with binders to pour the molten steel ladle for better overall lining

performance.

6. Producing bauxite cement

7. Abrasives

8. Ceramics industry

9. Chemistry industry for all kinds of aluminium compound.

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q:What is the main constituent of refractory brick?

- There are several refractory bricks, including clay brick, carborundum brick and chromium-carbon. The type you said may be refractory bricks made from bauxite.

- Q:Which are roofing fireproofing material?

- (1) Foamed concrete is a kind of fire-proof thermal inuslation matertial featured by good fire resistance and thermal insulation. Besides, it is also characterized by excellent sound proofing, penetration resistance, easy construction, safety and environmental protection without toxin and pollution. (2) Foam glass is featured by light weight, small heat conductivity coefficient and water absorbption, non-inflammability, fire resistance, high strength, no moulding, corrosion resistance, non-toxin and stable physical and chemical properties and thus widely used petroleum, chemical engineering and underground construction. It is also featured by thermal insualtion, heat/cold preservation and sound absorbption and thus can be used for thermal insulation of external wall and roof of civil builduing. Foam glass is featured by stable chemical property, easy to be processed and not easy to deforme, and durable. (3) With slag, basalt and other natural ore as the main raw material, rock wool, mineral wool and its products are made by high temperature melting into fiber, and then processing with binder. It has low thermal conductivity, fire resistance, easy construction and good effects of energy saving and thus is highly cost-effective. (4) With phenolic foam material as main material, phenolic resin plate is made by foaming thermoset phenolic resin. It is featured by light weight, fire resistance, no burning in the air, no smoking, non-toxin, no dropping and non-embrittlement and thus is an ideal thermal insulation material used in HAVC projects. Due to its high obturator formamen rate, low heat conductivity coefficient, good thermal insulation, water resistance and water vapor permeability, phenolic foam is an ideal thermal insulation material.

- Q:What are the physical properties of refractory material?

- The mechanical properties of refractory material include compressive strength, volume density and sclerosing, slag resistance, elastic modulus, thermal shock resistance, oxidation resistance, bibulous rate, fluidity, resilience, bond strength and slump, electrical conductivity, specific heat, heat capacity, the impact strength, linear change, torsional strength, stomatal aperture distribution, resistance to acid, etc. The use performance of refractory material include refractoriness, thermal emissivity, condensation, porosity, coefficient of thermal expansion. Thermal properties of refractory material include thermal conductivity, temperature conductivity, plasticity, the hydration resistance, creep performance. The physical properties of the refractory materials include structure performance, mechanical properties, shear strength, load softening temperature, CO erosion resistance. The structure properties of the refractory materials include porosity, alkali resistance and sintering. The operating performance of refractory material include consistency, tensile strength, the use performance and operating performance, wear resistance, bending strength, thermal properties.

- Q:What material is refractory material?

- Basic refractory materials, basic refractory, CaO, basic, MgO style alkaline earth oxide. The refractory materials mainly refers to magnesia refractories, dolomitic and lime refractory refractory. Main categories: (1) strongly basic magnesite brick, magnesia carbon brick, limestone and dolomite brick refractory materials;(2) alkalescent magnesia chrome refractories, forsterite refractory, magnalium and magnesia-chrome spinel refractory, basic refractory materials, high-temperature caustic slag, alkaline solvent resistance, strongly acidic slag flux or acidic refractory. The reaction is mainly used in steel furnace such as colour metal smelting furnace and cement kiln.

- Q:What are fireproofing materials?

- Plants often use the fireproof sealing material with steel structures without much modification. All the panels that meet the first-order fire protection requirements can be fireproofing materials. Like gypsum boards, aluminum sheets and so on. . Coatings are usually those with fine powder, high density and good sealing. Hardeners mainly depends on specific requirements. .

- Q:The manufacturing technique of refractory material

- The major components of alkaline refractory material include magnesium oxide and calcium oxide. The commonly used alkaline refractory material is magnesia bricks. The magnesia bricks with 80%~85% magnesium oxide has good resistance to basic slag and slag and higher refractoriness than clay bricks and silica bricks. It is mainly used in open hearth, oxygen blowing of converter, electric furnace and smelting non-ferrous metal equipment and other high temperature equipment. Refractory materials applied on special occasions include high temperature oxide refractory materials such as alumina, lanthanum oxide, beryllium oxide, calcium oxide, zirconium oxide, etc., refractory compounds such as carbide, nitride, boride, silicide and sulfide, etc., and high temperature composite materials, including metal ceramics, high temperature inorganic coating and fiber reinforced ceramics, etc. Consult and find reference for efractory materials production equipment, go to http://hi.baidu.

- Q:What material is used for making refractory stone bowl?

- Good refractory stone pot is carved from high-quality natural refractory stone in a professional way. But many are also made of synthetic materials, the price is lower, too.

- Q:What's the B grade fireproofing material?

- B1 grade ceiling material: gypsum board, fobrous plasterboard, cement particle board, mineral wool decorative acoustic panels, glass wool decorative acoustic board, perlite decorative acoustic board, flame retardant plywood, flame retardant medium density fiberboard, rock wool decorative sheet, flame retardant wood, aluminum foil composites, flame retardant phenolic laminate, aluminum foil glass fiber reinforced plastic composite material, etc.; B1 grade wall material: gypsum board, fibrous plasterboard, cement particle board, mineral wool board, glass wool board, perlite board, flame retardant plywood and medium density fiberboard, fireproof plastic decorative sheet, nonflammable double-sided particle board, multicolor coating, flame retardant wallpaper and wall cloth, flame retardant simulated granite decorative plates, magnesium oxychloride cement prefabricated wall panels, flame retardant glass fiber reinforced plastic plates, PVC plastic clapboards, high-strength and lightweight composite wallboards, fire-retardant molded wooden composite boards, flame retardant colored artificial boards, nonflammable glass fiber reinforced plastics, etc.

- Q:What level is the rock wool board fireproofing material ?

- The fire rating classification is a provision for all insulation materials, rather than to separately divide rock wool. Determine the value of the material fire rating according to the relevant test items of 8624. As the rock wool is made from basalt fusion, so it is the level A non-combustible material.

- Q:what is the fireproofing material of engine room? who knows it ?

- 1. The new type fire?retardant?coating in fire retardant coating, the expanded vermiculite, expanded perlite heat insulation material and cenosphere adiabatic powder, etc. These inorganic component, is a major part of the thick coating type of fireproof coating, and they also are the major factor affecting the level of performance of fireproof coatings. The fireproofing thermal insulation properties of fireproof coating, is mainly determined by the fire back surface temperature of this factor, but also related to the fire endurance. If it reaches the same temperature for a longer time, it shows that it's fireproof thermal insulation is better, and the fire endurance therefore is higher. 2. The new fireproof board new fireproof board now is welcomed by the people and the important factor is its environmental protection, and with the increasing high-rise buildings, the fire protection requirements and strength requirements are also rising, it is a big challenge for the performance and standard of the fireproof board.. Now fireproof board is mainly used siliceous material or calcareous materials, and then mixed with the fiber material, lightweight aggregate, adhesives and chemical additives, it is not only be fireproofing, but also improve their thermal insulation performance, and light weight, good carrying capacity, good durability, no aging problem, more importantly, it is good in environmental protection.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rotary Kiln/ Shaft Kiln Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords